1-6 n

27” Stacked Laundry Center

GENERAL INFORMATION

Using the Washer

Add Laundry Products

11

■Empty pockets. Loose change, buttons, or any small object

can pass under the agitator and become trapped, causing

unexpected sounds.

■Sort items by recommended cycle, water temperature,

and colorfastness.

■Separate heavily soiled items from lightly soiled.

■Separate delicate items from sturdy fabrics.

■Do not dry garments if stains remain after washing, because

heat can set stains into fabric.

■Treat stains promptly.

■Close zippers, fasten hooks, tie strings and sashes, and

remove non-washable trim and ornaments.

■Mend rips and tears to avoid further damage to items

during washing.

Helpful Tips:

■When washing waterproof or water-resistant items, load evenly.

■Use mesh garment bags to help avoid tangling when washing

delicate or small items.

■Turn knits inside out to avoid pilling. Separate lint-takers from

lint-givers. Synthetics, knits, and corduroy fabrics will pick up

lint from towels, rugs, and chenille fabrics.

NOTE: Always read and follow fabric care label instructions to

avoid damage to your garments.

1. Sort and prepare your laundry

USING YOUR WASHER

Add a measured amount of HE

detergent or single-dose laundry

packet into the basket.

If using Oxi-type boosters, color-safe

bleach, or fabric softener crystals, add

to the bottom of the washer basket before adding clothes.

IMPORTANT: Use only High Efciency detergents. The package

will be marked “HE” or “High Efciency.” Using non-HE

detergent will likely result in longer cycle times and reduced

rinsing performance. It may also result in component malfunction

and, over time, buildup of mold or mildew. HE detergents should

be low-sudsing and quick-dispersing to produce the right

amount of suds for the best performance. They should hold soil

in suspension so it is not redeposited onto clean clothes. Not all

detergents labeled as High Efciency are identical in formulation

and their ability to reduce suds. For example, natural, organic,

or homemade HE detergents may generate a high level of suds.

NOTE: Follow the manufacturer’s instructions to determine the

amount of laundry products to use.

2. Add laundry products

Figure X

Add a measured amount of HE detergent or single-dose

laundry packet into the basket.

If using Oxi-type boosters, color-safe bleach, or fabric soener

crystals, add to the boom of the washer basket before adding

clothes.

IMPORTANT: Use only High Eciency detergents. The

package will be marked “HE” or “High Eciency.” Using

non-HE detergent will likely result in longer cycle mes and

reduced rinsing performance. It may also result in component

malfuncon and, over me, buildup of mold or mildew. HE

detergents should be low-sudsing and quick-dispersing to

produce the right amount of suds for the best performance.

They should hold soil in suspension so it is not redeposited

onto clean clothes. Not all detergents labeled as High

Eciency are idencal in formulaon and their ability to

reduce suds. For example, natural, organic, or homemade HE

detergents may generate a high level of suds.

NOTE: Follow the manufacturer’s instrucons to determine

the amount of laundry products to use.

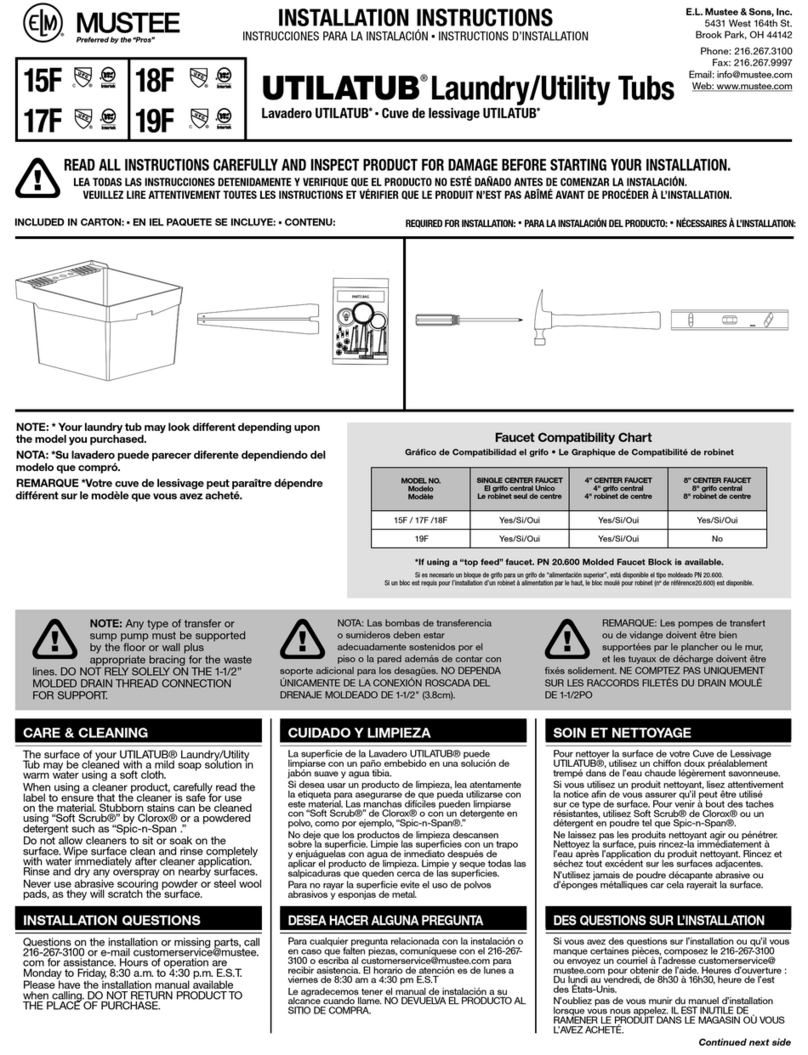

Add Liquid Chlorine Bleach to Dispenser

Do not overll, dilute, or use more than 1 cup (236 mL). Do

not use color-safe bleach or Oxi products in the same cycle

with liquid chlorine bleach.

12

5. Add fabric softener to dispenser

Pour a measured amount of liquid fabric

softener into dispenser; always follow

manufacturer’s directions for correct amount

of fabric softener based on your load size.

Dilute liquid fabric softener by lling the dispenser with warm

water until liquid reaches the underside of the rim. See max ll

line arrows. Do not overll.

Adding Liquid Fabric Softener Manually to Wash Load

During the nal rinse, wait until the washer has completed lling

and press the START/PAUSE button to pause the washer. Lift

the lid and add the measured recommended amount of liquid

fabric softener. Do not allow liquid fabric softener to spill, splash,

drip, or run into the basket or on load. Do not use more than

the recommended amount. Close the lid and press the START/

PAUSE button again to start the washer.

Do not overll, dilute, or use more than 1 cup (236 mL).

Do not use color-safe bleach or Oxi products in the same

cycle with liquid chlorine bleach.

Load garments in loose heaps evenly around basket wall.

For best results, do not pack the load tightly. Do not wrap large

items such as sheets around the agitator; load them in loose

piles around the sides of the basket. Try mixing different-sized

items to reduce tangling.

3. Load laundry into washer

IMPORTANT: Do not tightly pack or force items into washer.

Items need to move freely for best cleaning and to reduce

wrinkling and tangling.

Turn cycle knob to choose your wash cycle. For more

information, see “Washer Cycle Guide.”

6. Select cycle

4.

Add liquid chlorine bleach

to dispenser

MAX FILL

Liquid

Chlorine Bleach

Figure X

Add Fabric Softener to Dispenser

12

5. Add fabric softener to dispenser

Pour a measured amount of liquid fabric

softener into dispenser; always follow

manufacturer’s directions for correct amount

of fabric softener based on your load size.

Dilute liquid fabric softener by lling the dispenser with warm

water until liquid reaches the underside of the rim. See max ll

line arrows. Do not overll.

Adding Liquid Fabric Softener Manually to Wash Load

During the nal rinse, wait until the washer has completed lling

and press the START/PAUSE button to pause the washer. Lift

the lid and add the measured recommended amount of liquid

fabric softener. Do not allow liquid fabric softener to spill, splash,

drip, or run into the basket or on load. Do not use more than

the recommended amount. Close the lid and press the START/

PAUSE button again to start the washer.

Do not overll, dilute, or use more than 1 cup (236 mL).

Do not use color-safe bleach or Oxi products in the same

cycle with liquid chlorine bleach.

Load garments in loose heaps evenly around basket wall.

For best results, do not pack the load tightly. Do not wrap large

items such as sheets around the agitator; load them in loose

piles around the sides of the basket. Try mixing different-sized

items to reduce tangling.

3. Load laundry into washer

IMPORTANT: Do not tightly pack or force items into washer.

Items need to move freely for best cleaning and to reduce

wrinkling and tangling.

Turn cycle knob to choose your wash cycle. For more

information, see “Washer Cycle Guide.”

6. Select cycle

4.

Add liquid chlorine bleach

to dispenser

MAX FILL

Liquid

Chlorine Bleach

12

5. Add fabric softener to dispenser

Pour a measured amount of liquid fabric

softener into dispenser; always follow

manufacturer’s directions for correct amount

of fabric softener based on your load size.

Dilute liquid fabric softener by lling the dispenser with warm

water until liquid reaches the underside of the rim. See max ll

line arrows. Do not overll.

Adding Liquid Fabric Softener Manually to Wash Load

During the nal rinse, wait until the washer has completed lling

and press the START/PAUSE button to pause the washer. Lift

the lid and add the measured recommended amount of liquid

fabric softener. Do not allow liquid fabric softener to spill, splash,

drip, or run into the basket or on load. Do not use more than

the recommended amount. Close the lid and press the START/

PAUSE button again to start the washer.

Do not overll, dilute, or use more than 1 cup (236 mL).

Do not use color-safe bleach or Oxi products in the same

cycle with liquid chlorine bleach.

Load garments in loose heaps evenly around basket wall.

For best results, do not pack the load tightly. Do not wrap large

items such as sheets around the agitator; load them in loose

piles around the sides of the basket. Try mixing different-sized

items to reduce tangling.

3. Load laundry into washer

IMPORTANT: Do not tightly pack or force items into washer.

Items need to move freely for best cleaning and to reduce

wrinkling and tangling.

Turn cycle knob to choose your wash cycle. For more

information, see “Washer Cycle Guide.”

6. Select cycle

4.

Add liquid chlorine bleach

to dispenser

MAX FILL

Pour a measured amount of liquid fabric soener into

dispenser; always follow manufacturer’s direcons for correct

amount of fabric soener based on your load size.

Dilute liquid fabric soener by lling the dispenser with warm

water unl liquid reaches the underside of the rim. See max ll

line arrows. Do not overll.

Adding Liquid Fabric Soener Manually to Wash Load

During the nal rinse, wait unl the washer has completed

lling and press the START/PAUSE buon to pause the washer.

Li the lid and add the measured recommended amount of

liquid fabric soener. Do not allow liquid fabric soener to

spill, splash, drip, or run into the basket or on load. Do not use

more than the recommended amount. Close the lid and press

the START/ PAUSE buon again to start the washer.

Figure X