Platinum Split

TABLE OF CONTENTS

Quick Reference Guide

Evaporator Unit ........................................................ 2

Controller Layout & Specications ......................................... 3

Fully Ducted Unit & Specications ......................................... 4

Receiving & Inspecting the System ........................................ 5

Before You Start .......................................................... 6

Preparing the Wine Cellar ................................................. 7

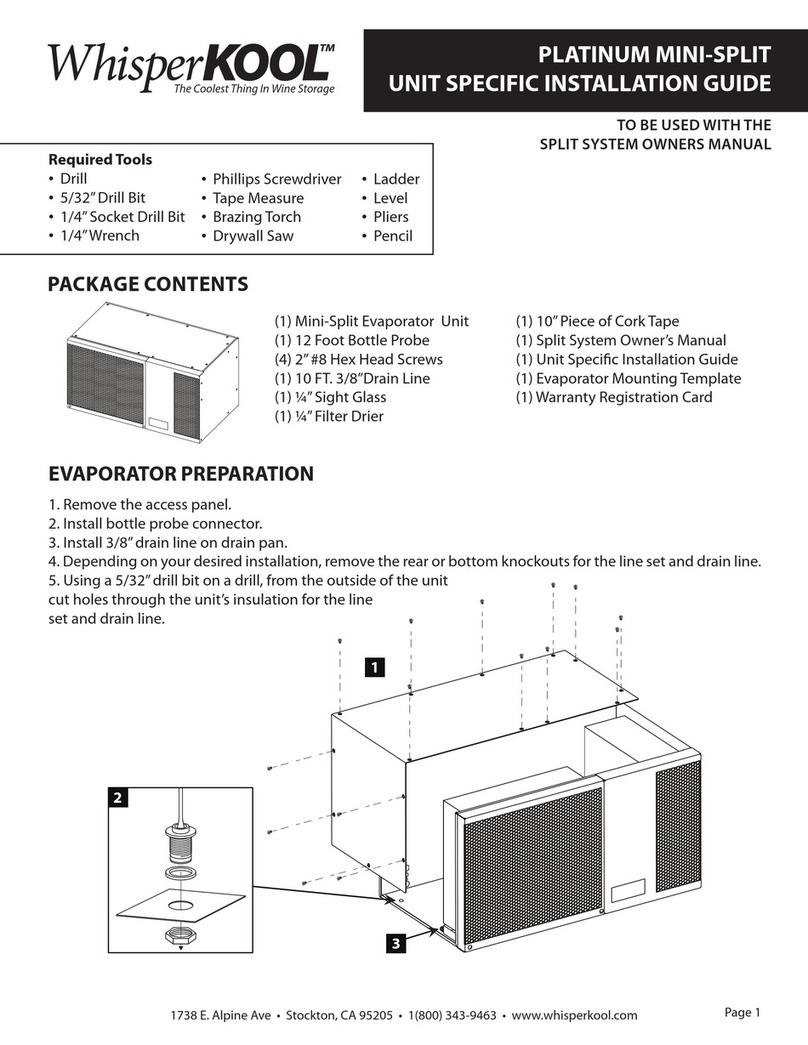

Preparing the Evaporator Unit ............................................ 10

Installing the Evaporator Unit ............................................. 11

Drain Line................................................................ 13

Liquid Measuring Thermostat (Bottle Probe) ............................... 14

Installing the Fully Ducted Evaporator Unit ................................ 15

Remote Keypad .......................................................... 18

Platinum Split with Humidity Wiring Diagram.............................. 19

Platinum Split Wiring Diagram ............................................ 20

4000 Condenser Wiring Diagram .......................................... 21

8000 Condenser Wiring Diagram .......................................... 22

8000 Condenser Wiring Schematic ........................................ 23

Active Humidity Option. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Humidistat Installation ................................................... 25

Preparing the Condensing Unit ........................................... 27

Cold Weather Start Installation............................................ 27

Installing the Condensing Unit ............................................ 29

Line Set Piping Diagrams ................................................. 32

Installing the Wall Mount Kit .............................................. 35

Installing the Ducted Plenum ............................................. 36

System Operation ........................................................ 37

Controller Functions...................................................... 38

Maintenance Schedule ................................................... 41

Troubleshooting Guide ................................................... 42

Bypass Test Procedure .................................................... 44

Technical Assistance & Accessories ........................................ 45

Copyright © 2012. WhisperKOOL. All rights reserved.

WhisperKOOL copyrights this manual, the product design, and the design concepts, with all rights reserved. Your rights

with regard to the hardware and manual are subject to the restrictions and limitations imposed by the copyright laws of

the USA. Under copyright laws, this manual may not be copied, reproduced, translated, transmitted, or reduced to any

printed or electronic medium or to any machine-readable form, for any purpose, in whole or in part, without the written

consent of WhisperKOOL.

Every effort has been made to ensure that the information in this manual is accurate. WhisperKOOL is not responsible for

printing or clerical errors.

WhisperKOOL reserves the right to make corrections or improvements to the information provided and to the related

hardware at any time, without notice.

Vinothèque and WhisperKOOL are registered trademarks, and ECE is a trademark of WhisperKOOL. All rights reserved.

Mention of third-party products is for informational purposes only and constitutes neither an endorsement nor a

recommendation. WhisperKOOL assumes no liability with regard to the performance or use of these products.

07.16.2015