Wall & Ceiling Framing

Build wine cellar walls using standard 2x4 or 2x6 construction methods and ceiling joists

following the guidelines of local and state codes in your area. The general rule for a cellar

is the thicker the walls, the higher the insulation factor, the better the cellar remains at a

consistent temperature.

Insulation

Insulation is REQUIRED with the use of the WhisperKOOL product; Standard “Fiberglass”

or “Rigid Foam” insulation is normally used in cellar construction, or in some cases,

“blown in” insulation is used. It is very important that all walls and ceiling be insulated to

keep the cellar temperature as consistent as possible during the summer and winter months.

The R factor or thickness of insulation is determined by the thickness of the walls and

ceiling. For example, fiberglass insulation of R13 is designed to be used in a 2x4 wall.R19

is used in a 2x6 wall. It is important to use the correct insulation for the wall thickness.

Preparing the

Wine Cellar

-4-

PREPARING THE

WINE CELLAR

The performance and life of your WhisperKOOL System are contingent upon the steps you

take in preparing the wine cellar.

It is highly recommended that you obtain the assistance of a wine

storage professional.

Wine storage professionals work with licensed contractors, refrigeration technicians, and

racking companies to build well-insulated, beautiful, and protective wine cellars. In some

areas of the country, these professionals are not available. We have put together some

useful tips to assist in the installation process.

Our recommendations are meant to act as a guide in the process of building a proper

enclosure. Your intended location may have specific needs that we do not address.

Vapor Barrier

Vapor barrier is REQUIRED if a climate control cooling unit is installed to keep the cellar at

the correct temperature and humidity. 6mm plastic sheeting is applied to the warm side of the

cellar walls.The vapor barrier must be either applied to the outside walls and ceiling, or if it

is impossible to get to the outside, then the plastic must be applied from within the cellar. The

most common method is to wrap the entire interior, leaving the plastic loose in the stud cavity

so the insulation can be placed between each stud. All walls and ceiling must be wrapped in

plastic for a complete vapor barrier.

In areas of humidity, such as the southern and gulf states, the vapor barrier will prevent

infiltration of warm moist air. The moist air can cause mold to form. The cooling unit will strip

excessive moisture from the air and create water, which will need to be dissipated back out

of the cellar using the Condensate Evaporator system or drain line. In dry climates, the vapor

barrier will provide more control over retaining the higher correct humidity within the cellar.

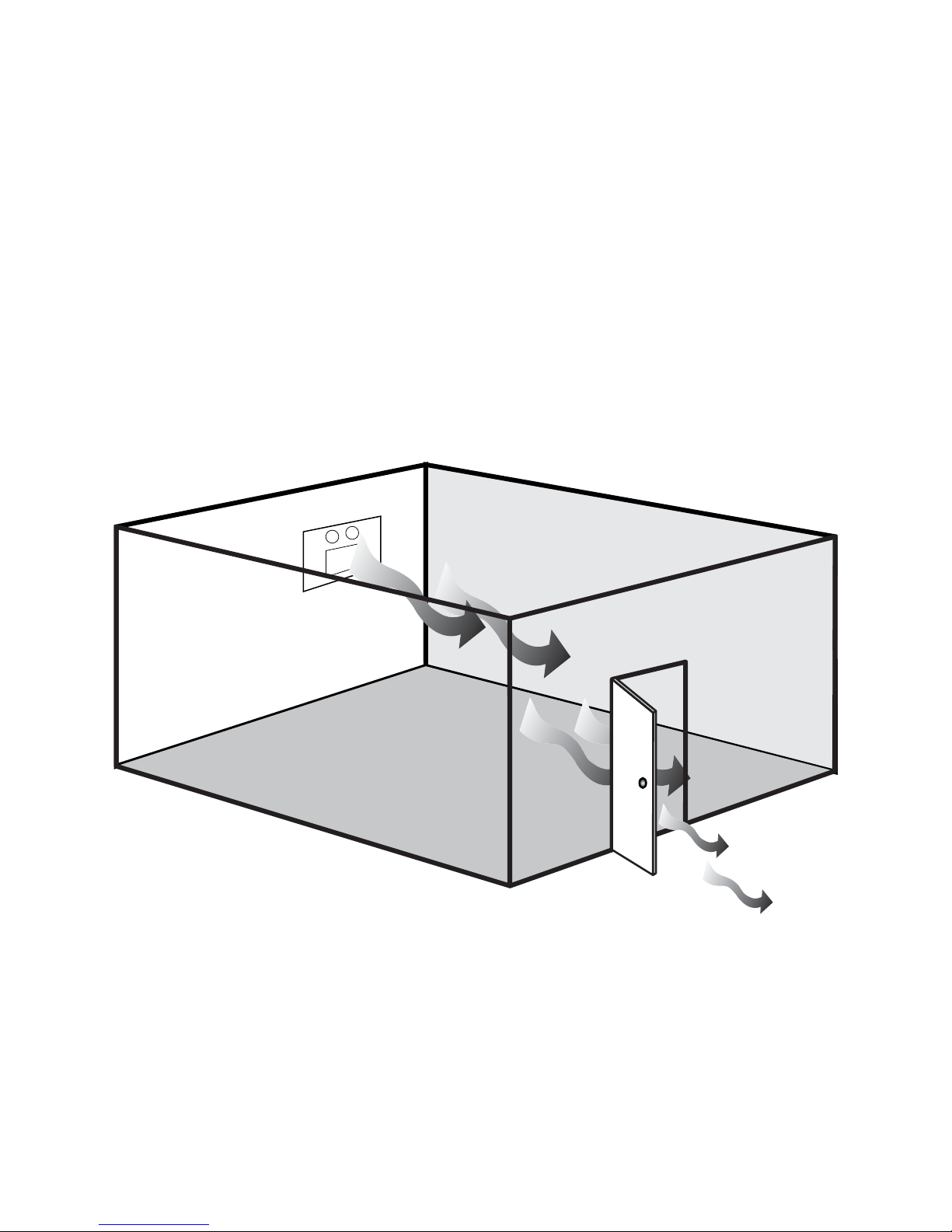

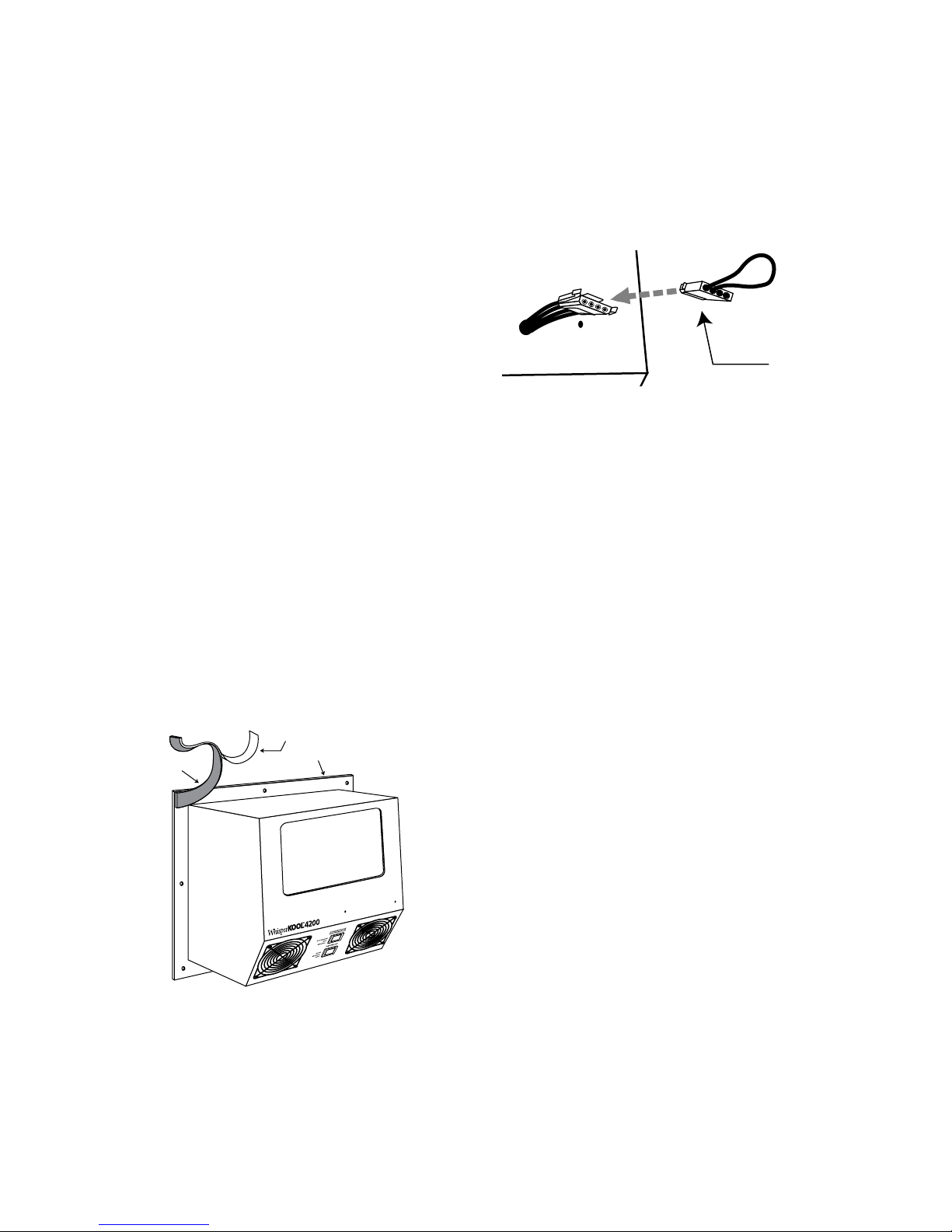

Ducting

The unit is designed to exhaust into an open area. Any attempt to duct the exhaust ports

to redirect airflow will result in voiding the warranty. The fans are not designed to push air

through a restricted duct system. The fans and compressor will be over worked and may

result in premature failure.