WhisperGLIDE Wheelchair Accessible Swing User manual

Other WhisperGLIDE Outdoor Furnishing manuals

Popular Outdoor Furnishing manuals by other brands

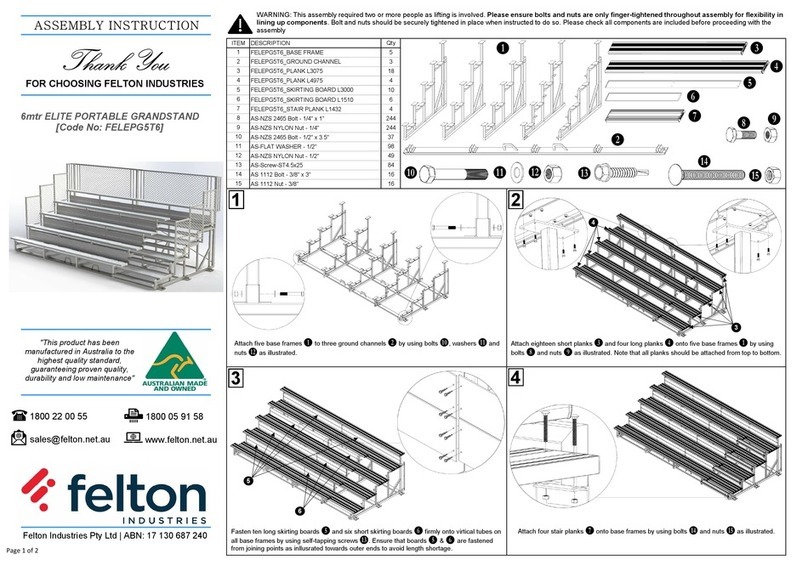

felton industries

felton industries FELEPG5T6 Assembly instruction

Dreamo

Dreamo OTF-503S quick start guide

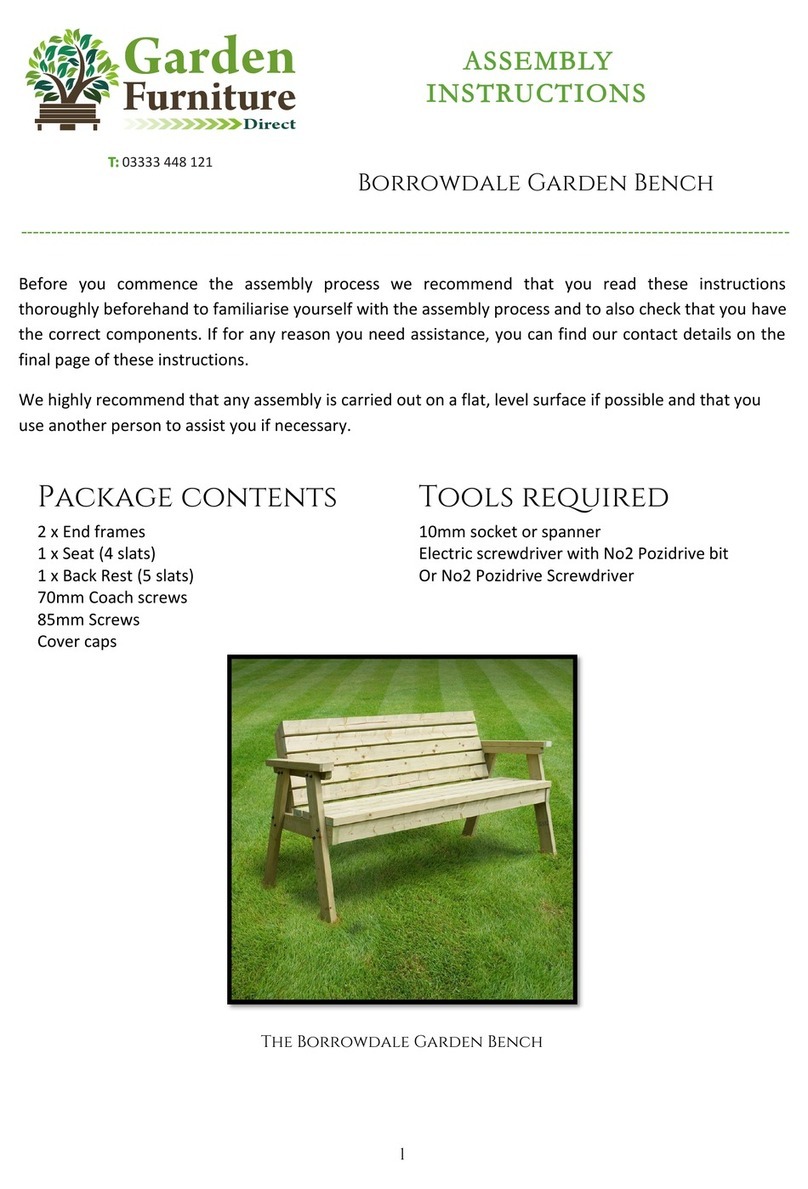

Garden Furniture Direct

Garden Furniture Direct Borrowdale Assembly instructions

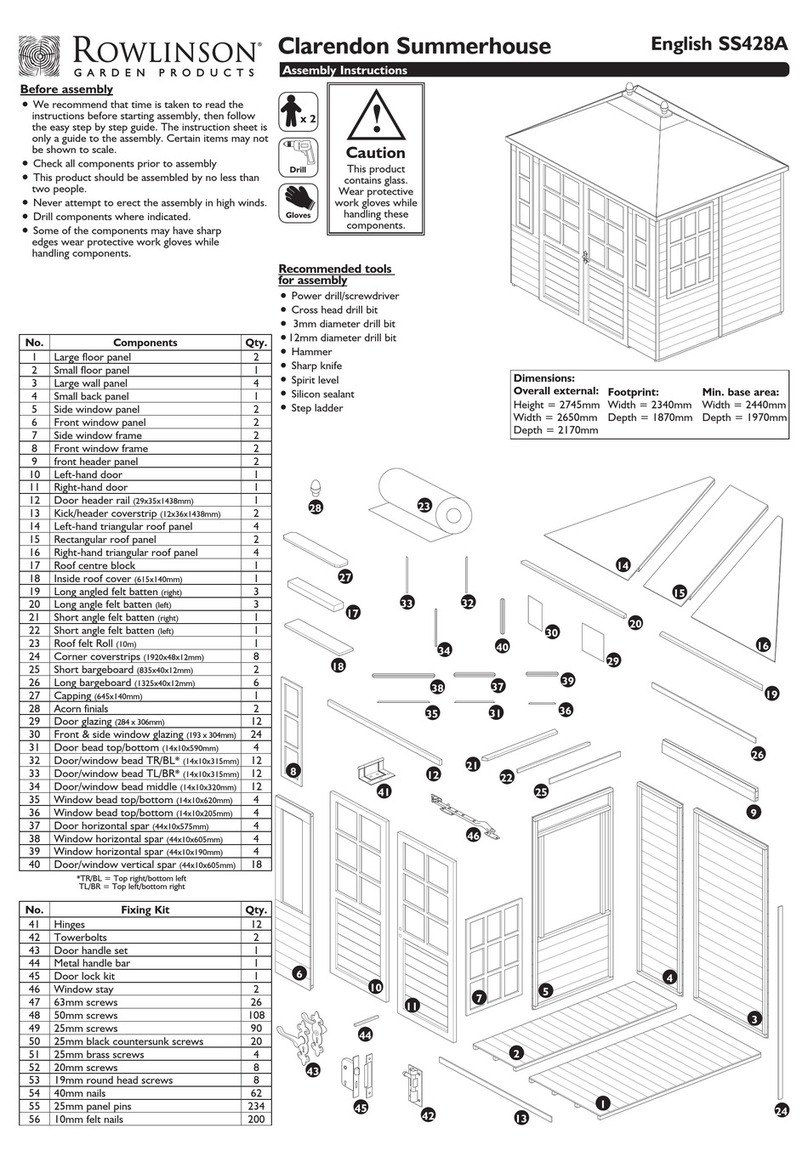

Rowlinson

Rowlinson Clarendon Assembly instructions

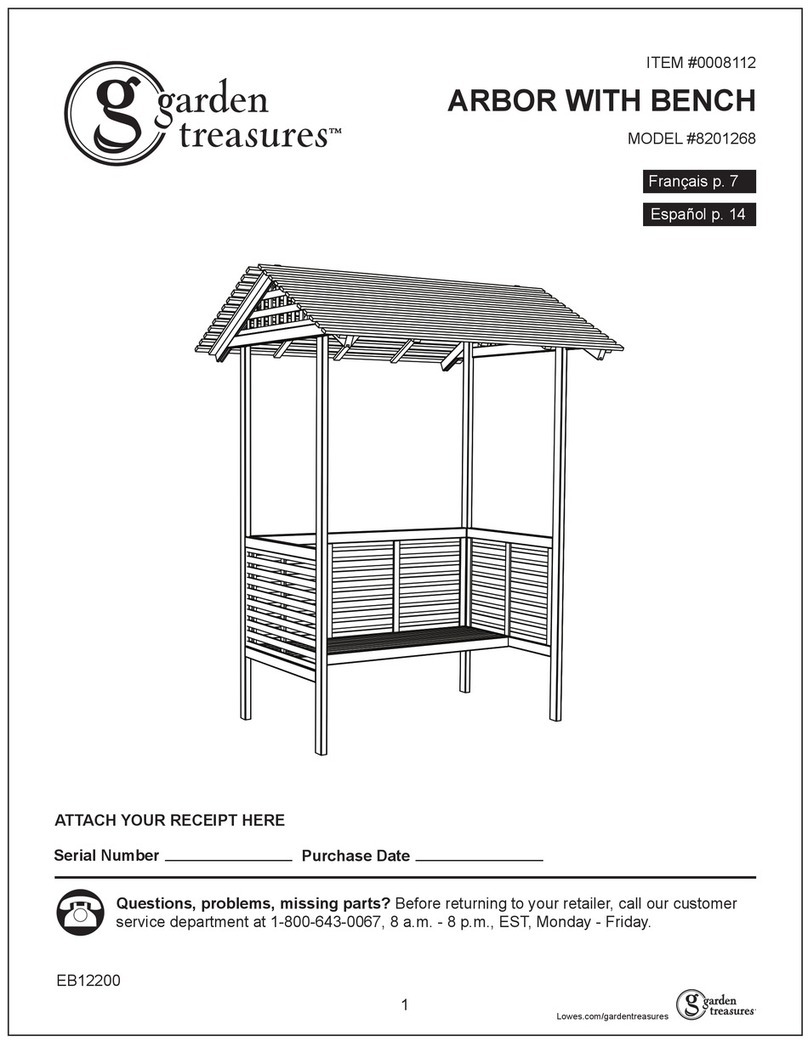

Garden Treasures

Garden Treasures 8201268 Assembly instructions

Safavieh Outdoor

Safavieh Outdoor Marson PAT7062 quick start guide

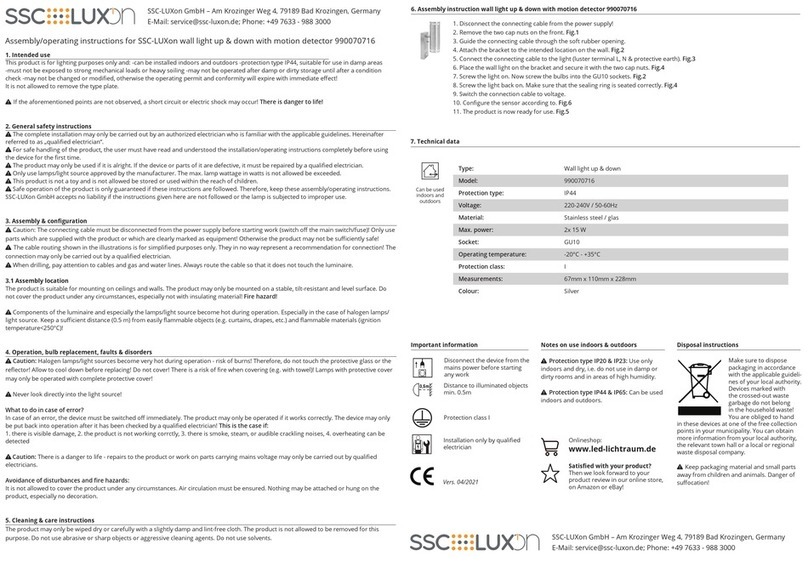

SSC-LUXon

SSC-LUXon 990070716 Assembly & operating instructions

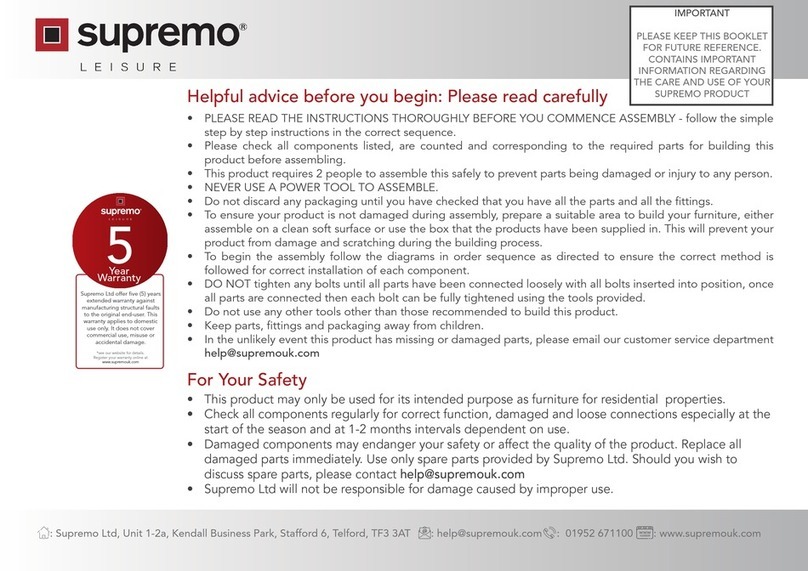

supremo LEISURE

supremo LEISURE 2-Seat Stool 110*40cm Assembly instruction

Hatteras Hammocks

Hatteras Hammocks DCA1-K-HH instructions

Lemeks

Lemeks Palmako PA120-5959 Assembly, installation and maintenance manual

OLT

OLT 24 Assembly manual

forest-style

forest-style HACIENDA 2354 Building instructions

Courtyard Creations

Courtyard Creations RUS0188-WM Assembly instructions

kingsley-bate

kingsley-bate MC-55 Assembly instructions

Weltevree

Weltevree Carrier product manual

Grange Fencing

Grange Fencing Elite Arch Assembly instructions

Grosfillex

Grosfillex AUVENT YR14 Assembly instructions

X-METAL

X-METAL EAGLE 33511 Assembly instructions