White Rotary 1202 User manual

Other White Sewing Machine manuals

White

White 1911 User manual

White

White 734 Specifications

White

White Super Lock 734 User manual

White

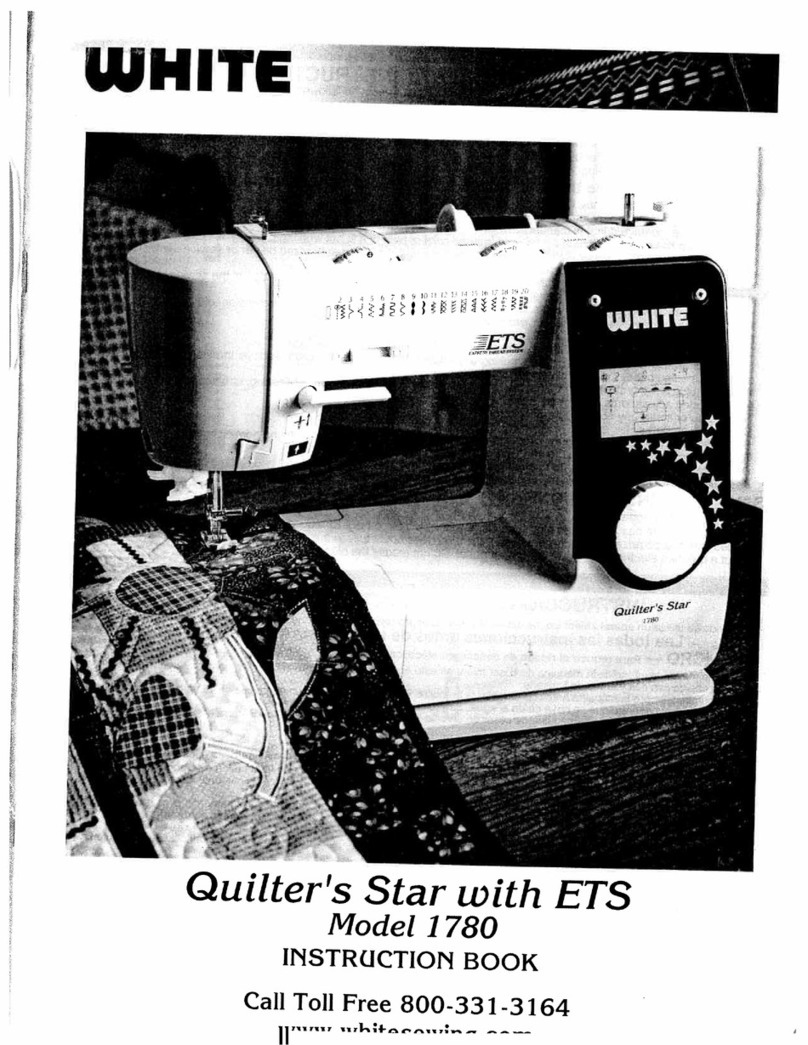

White Quilter's Star 1780 User manual

White

White 221N User manual

White

White 1730 User manual

White

White 1927 User manual

White

White Snow Boss 750 User manual

White

White 656 User manual

White

White 310 Specifications