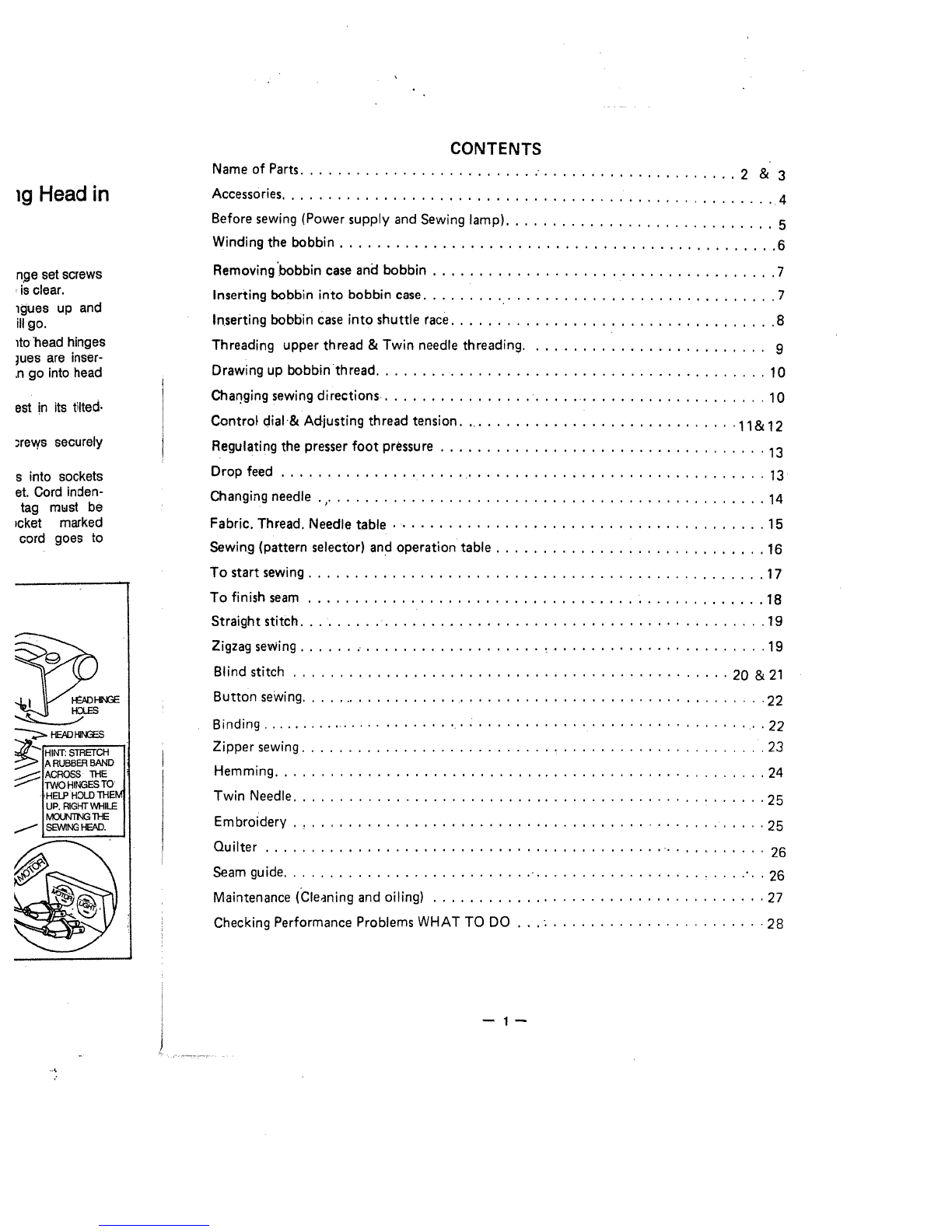

CONTENTS

Name of

Parts.........,.,,,..,,............

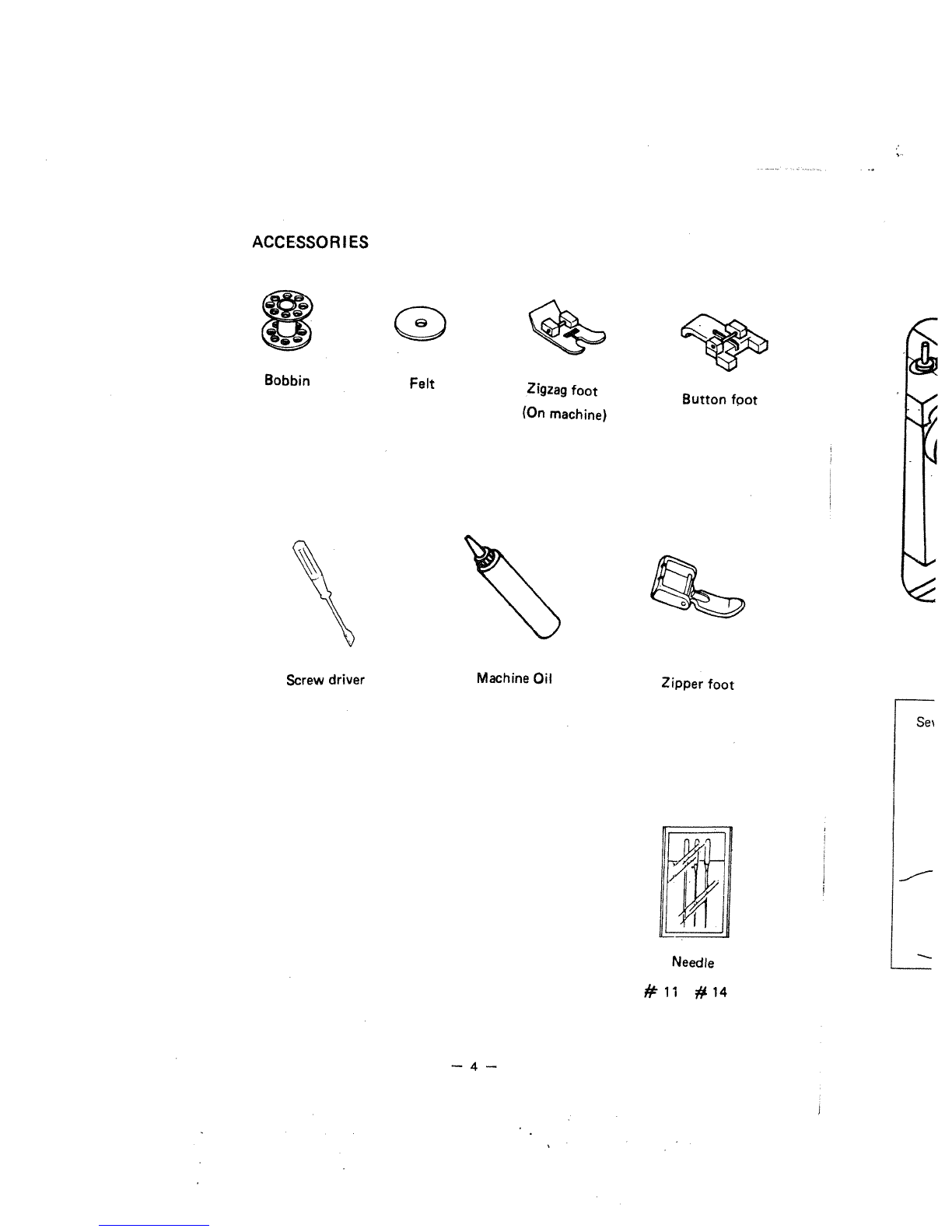

Accessories

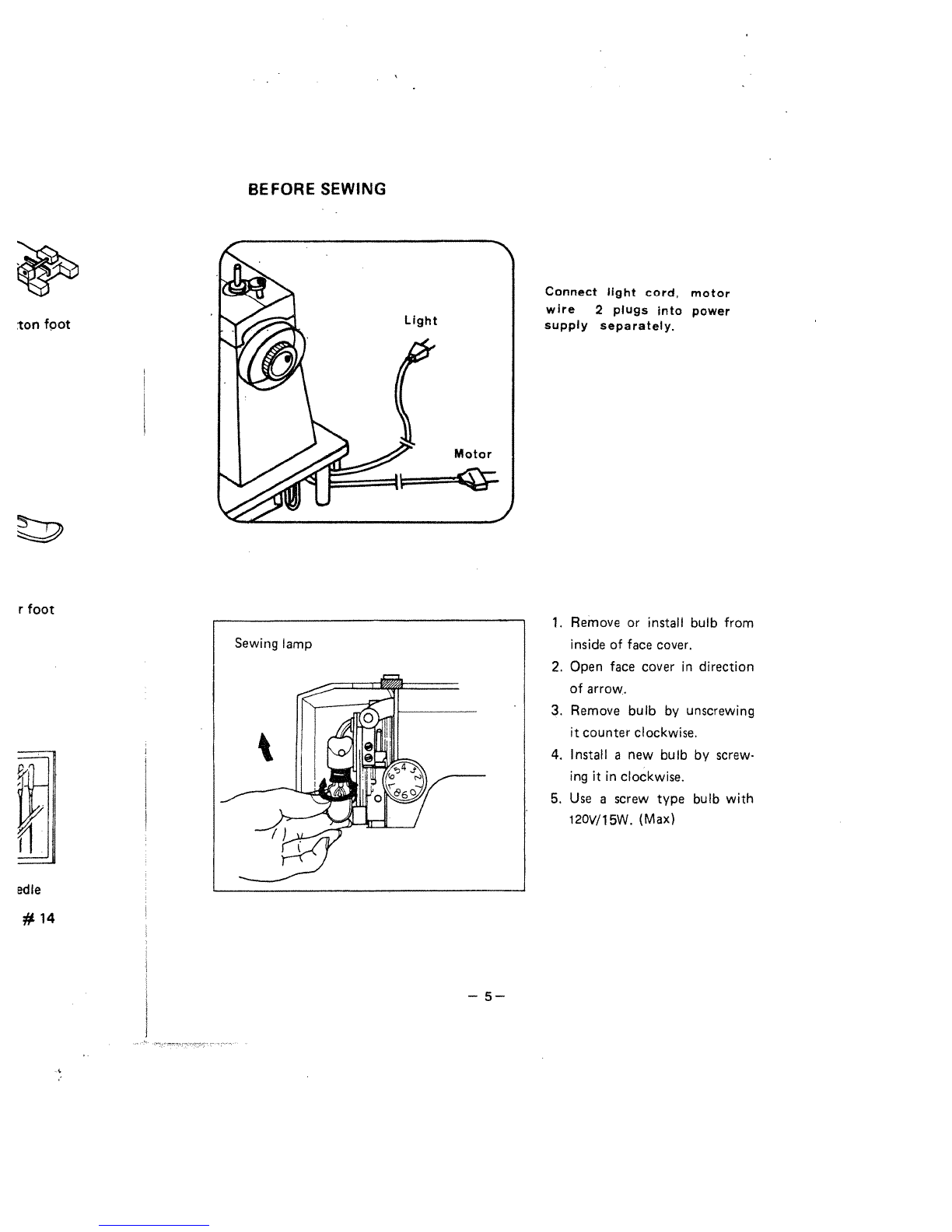

Before

sewing

(Power

supply

and Sewing

lamp)

Winding

the

bobbin

Removing

bobbin

case

and

bobbin

Inserting bobbin

into bobbin

case

Inserting bobbin

case

into

shuttle

race

Threading

upper

thread

&

Twin

needle

threading.

Drawing

up

bobbin

thread

Changing

sewing

directions.

Contr&

dial

&

Adjusting

thread tension.

Regulating the

presser

foot

pressure

Drop

feed

Changing

needle

.

Fabric.

Thread.

Needle

table

Sewing

(pattern

selector)

and

operation

table

To

start

sewing

To

finish

seam

Straight

stitch

Zigzag

sewing

Blind

stitch

Button

sewing

Binding

Zipper

sewing

Hemming

Twin

Needle

Embroidery

Quilter

Seam

guide

Maintenance

(Cle.3ning

and

oiling)

Checking

Performance

Problems

WHAT

TO DO

2&3

4

5

6

7

7

9

10

10

11&12

13

13

14

15

16

17

18

19

19

20&21

22

22

23

24

25

25

26

26

27

28

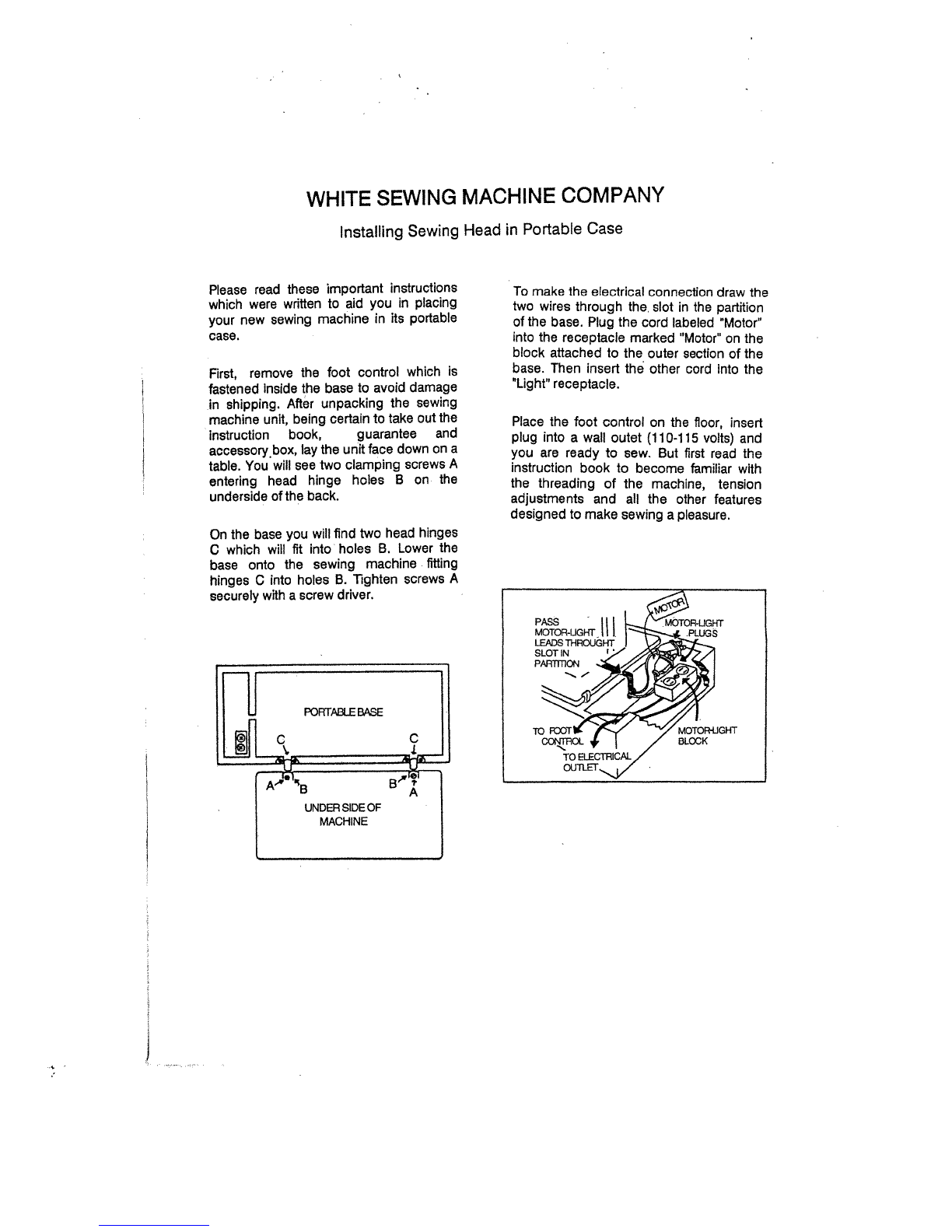

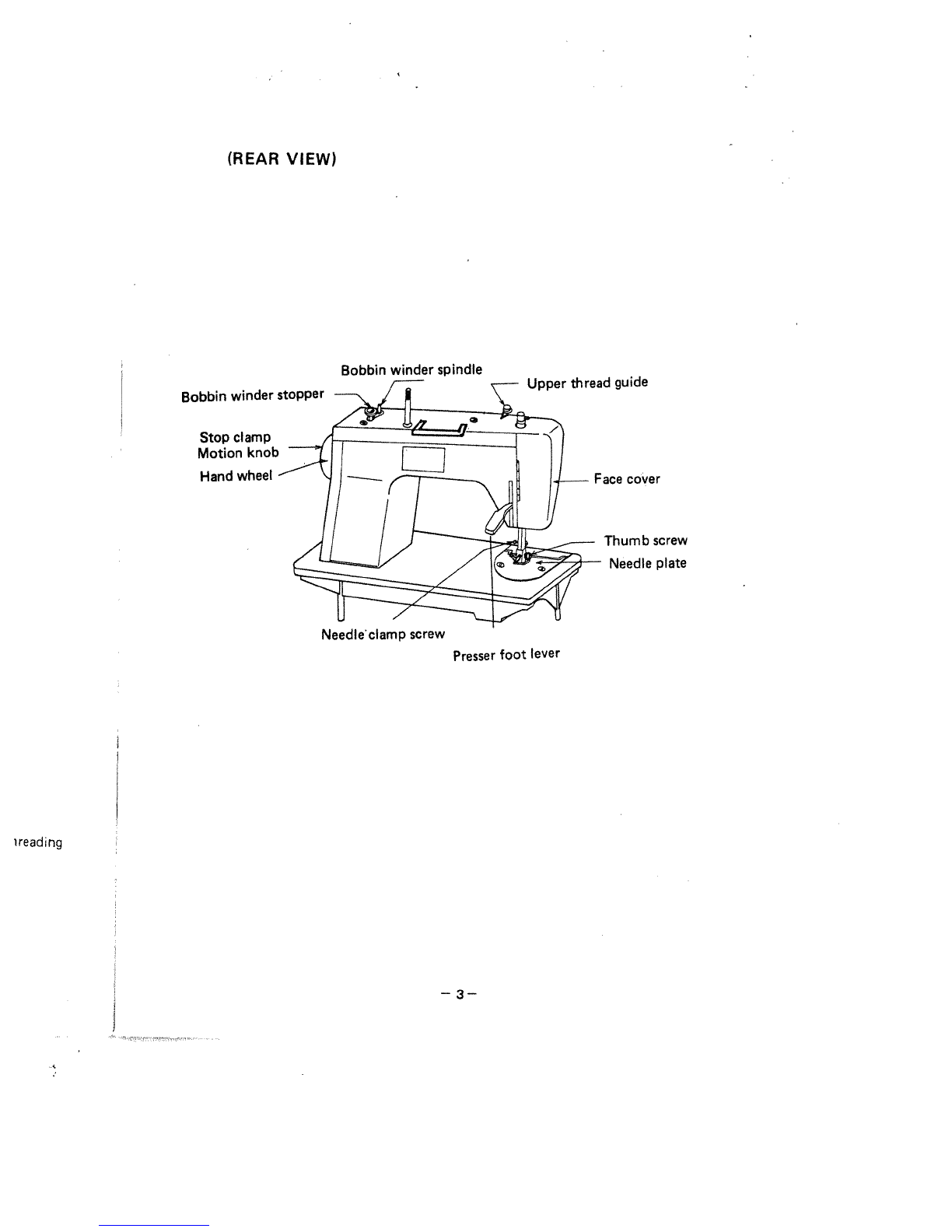

Head

in

ne

set

screws

is

clear.

gues

up

and

ill

go.

to

bead

hinges

ues

are

inser

.n

go

into

head

est

in

its

tilted

Drews

securely

5

into

sockets

et.

Cord

inden

tag

must

be

cket marked

cord

goes

to

8

—

1—•