page

8

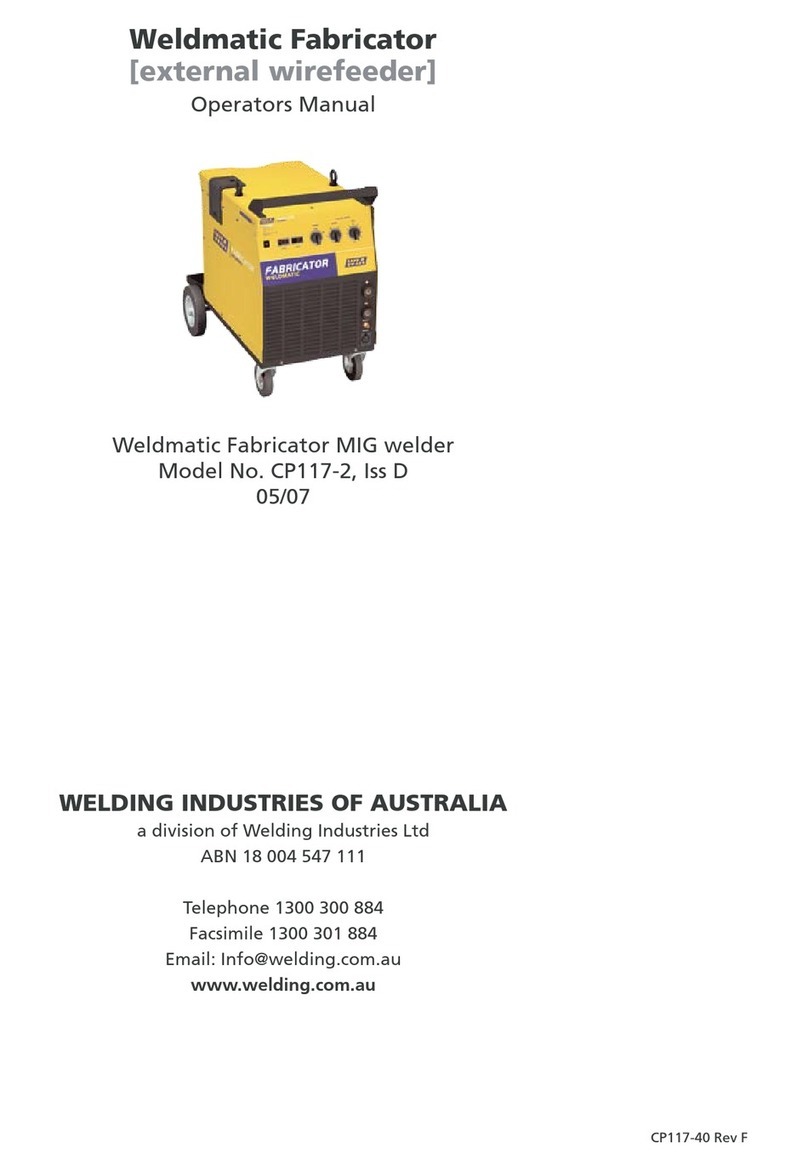

TIGARC

140DC

MANUAL

To

strike the arc, drag the end of the electrode along the workpiece as if

strikinga match. As the arc initiates,

lift

the

electrode slightly away, aiming to

establish an arc length of approximately 3mm.

As

the electrode end is consumed,

feed the electrode into thearc in order to maintain a constant arc length. As a

generalrule, the arc should be held as short as possible while still giving stable

burn off and good weld appearance. An arc which is too long causes an unwieldy

flow

of

metal with a rough weld apFearance and reduced penetration. An arc too

short leads to a narrow weld deposit and "stuttery" arc characteristic, and the

electrode is liable

to

freeze onto the workpiece.

As the solidified weld deposit forms, move the end of the electrode slowly

along the weld path, aiming to maintaina

poot

of moltenweld metal behind the arc.

Decreasing this rate

of

travel will result in a wider weld deposit, and similarly

increasing

it

will narrow the weld deposit. Always fit1 the crater which tends to form

at the endof a weld deposit, by pausing momentarily before withdrawing the

electrode to break the arc. Unfilled craters are a point of weakness, and can lead

toweld cracking.

onstantmolten

pool

widthmeans

ONSTANT

beadwidth

StrikingthearcMaintainsteady

arc

length

2

FIGURE

4.

MANUAL METAL

ARC

WELDING.

5.

MAINTENANCE

Care should be taken to prevent excessive build-up of dust and dirt within the

welding power source. It isrecommendedthat at regular intervals,according to the

prevailing conditions, the machine covers be removed and any accumulated dust

be removedby the use of dry, low pressurecompressedair, or avacuum cleaner.

6.

FAULT FINDING, NOWELDING CURRENT

Check that Mains Supply is available at the TIGARC 140DC Power Source, i.e.

that the fan

is

running. Check for continuity of the welding current circuit, i.e., work

lead,work clamp and electrode holder.

TheTIGARC

140DC

welding power source incorporates an inbuilt protection

device which will trip if the unit is overloaded. In this event the machine will not

deliver welding current until the overload device hasbeenMANUALLYreset.The

overload device cannot be reset immediately after it has tripped. 8efore resetting,

establish and correct the causeof the overload condition. Thereset button is

located on the rear panel,just above the Supply Flexible Cableentry.

If

equipment failure

is

suspected, forward the unit to yournearest WIASales

and ServiceBranch, or qualified serviceagent.