~

WELDMATIC

335

MANUAL

Paae

7

-

-cl

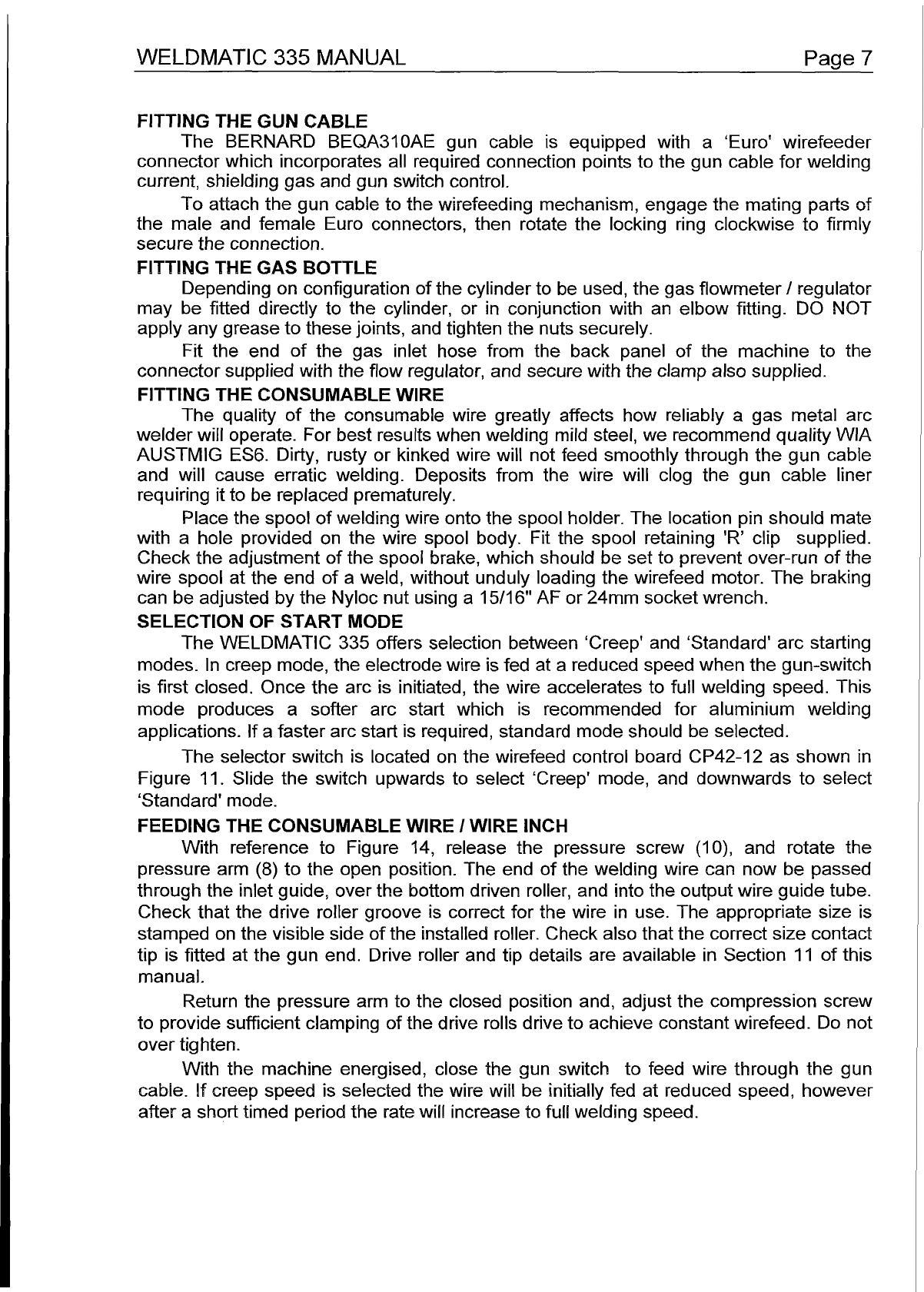

FITTINGTHE GUN CABLE

The BERNARDBEQA31OAEguncable is equippedwitha 'Euro8wirefeeder

connector which incorporates all required connection pointsto the gun cable for welding

current, shieldinggas and gun switch control.

To attach the guncable

to

the wirefeeding mechanism, engagethe mating

parts

of

the male and female Euroconnectors,thenrotate the lockingring clockwise to firmly

secure the connection.

FITTINGTHE GAS BOTTLE

Dependingon configuration of the cylinderto be used,the gas flowmeter

/

regulator

may be fitted directly to the cylinder, or in conjunctionwithan elbow fitting.

DO

NOT

apply any greaseto thesejoints, and tightenthe nuts securely.

Fit the end of the gasinlet hose from the backpanel of the machineto the

connector supplied with the flow regulator, and secure withthe clampalso supplied.

FITTINGTHE CONSUMABLE WIRE

The quality of the consumable wiregreatlyaffectshowreliablya gas metal arc

welder will operate. Forbest results when welding mild steel, werecommendquality WIA

AUSTMIG ES6. Dirty, rusty

or

kinked wire will not feed smoothly through the gun cable

and will cause erratic welding.Deposits from thewire will clog the gun cable liner

requiring

it

to be replacedprematurely.

Placethe

spool

of welding wire ontothe spool holder. The location pin should mate

withaholeprovidedon the wirespoolbody.Fitthe spool retaining'R' clip supplied.

Check the adjustment

of

the spool brake, which should be set to prevent over-run of the

wire spool at the end of a weld, without unduly loading the wirefeed motor. The braking

can be adjusted bythe Nyloc nut using a 15/16"

AF

or 24mm socket wrench.

SELECTION

OF

START MODE

The

WELDMATIC

335

offers selection between 'Creep' and 'Standard' arc starting

modes. In creep mode,the electrode wireisfed at a reduced speedwhen thegun-switch

is

first closed. Once the arc is initiated, the wire accelerates to full welding speed. This

mode producesasofterarcstartwhich is recommended for aluminium welding

applications. If a faster arc startis required, standard modeshould be selected.

The selector switch is located on the wirefeed control board CP42-12 as shown in

Figure 11.Slide the switch upwards to select'Creep' mode, and downwards to select

'Standard' mode.

FEEDINGTHE CONSUMABLE WIRE

I

WIRE INCH

Withreference to Figure14,release the pressurescrew (IO), and rotate the

pressure arm

(8)

to the open position. The end of the welding wire can now be passed

through the inlet guide, over the bottom driven roller, andintothe output wire guide tube.

Check that the drive roller groove

is

correct for the wire in use. The appropriate size is

stamped onthe visible side of the installed roller. Check also thatthe correct size contact

tip is fitted at the gun end. Drive roller and tip details are available in Section

11

of this

manual.

Return the pressure arm to the closed position and, adjust the compressionscrew

to provide sufficient clamping of the drive rolls driveto achieve constantwirefeed. Do not

over tighten.

Withthe machine energised,close the gun switch to feedwire through the gun

cable.

If

creep speed

is

selected the wire will be initially fed at reduced speed, however

after a

short

timed periodthe ratewill increaseto

full

welding speed.