WWW.WIDDDERTOOLS.COM®2

(203) 777-5395

SAFETY PRECAUTIONS:

Warning: When using air tools, basic safety precautions should always be followed to

reduce the risk of injury, including the following:

1. Avoid Accidental Starting.

-Keep throttle shutoff closed when transporting or repositioning

2. Disconnect Machine.

-This tool should be disconnected when not in use. If air is shutoff, tool should

be discharged of any stored air pressure.

3. Maximum Air Pressure

-Maximum air pressure is 135 PSI.

-Use clean, lubricated, regulated air.

4. Protect Airlines

-Avoid using excessive length airlines. Extended airlines reduce tool power and

are a working hazard.

-Inspect all airlines for safe condition before use.

5. Maintain Tool.

-Use sharp blades and keep Saw clean for optimum performance.

-Keep handles clean, dry and free from oil and grease.

-This tool, like all air tools, will provide best performance with

lubrication.

-Use WIDDER®Air Tool Lube for best performance

6. Do Not Force Tool.

-Use tool mounted in WIDDER®clamp with clamp tightly secured to work

piece.

-Cut should be performed with adequate force to develop chips during cutting

but not so as to stall the tool under load.

7. Support Work Piece

-Be sure to support the work piece on both sides of any cut. An

unsupported work piece can sag, pinching the blade and causing the blade to

break or shatter.

8. Dress Properly.

-Do not wear loose clothing or jewelry as they can be caught in moving parts.

-Work gloves and non-skid footwear are recommended.

-Wear ear protection.

-Wear safety glasses.

9. Maintenance.

-Maintenance should be performed by a WIDDER®Factory Authorized

Service Representative.

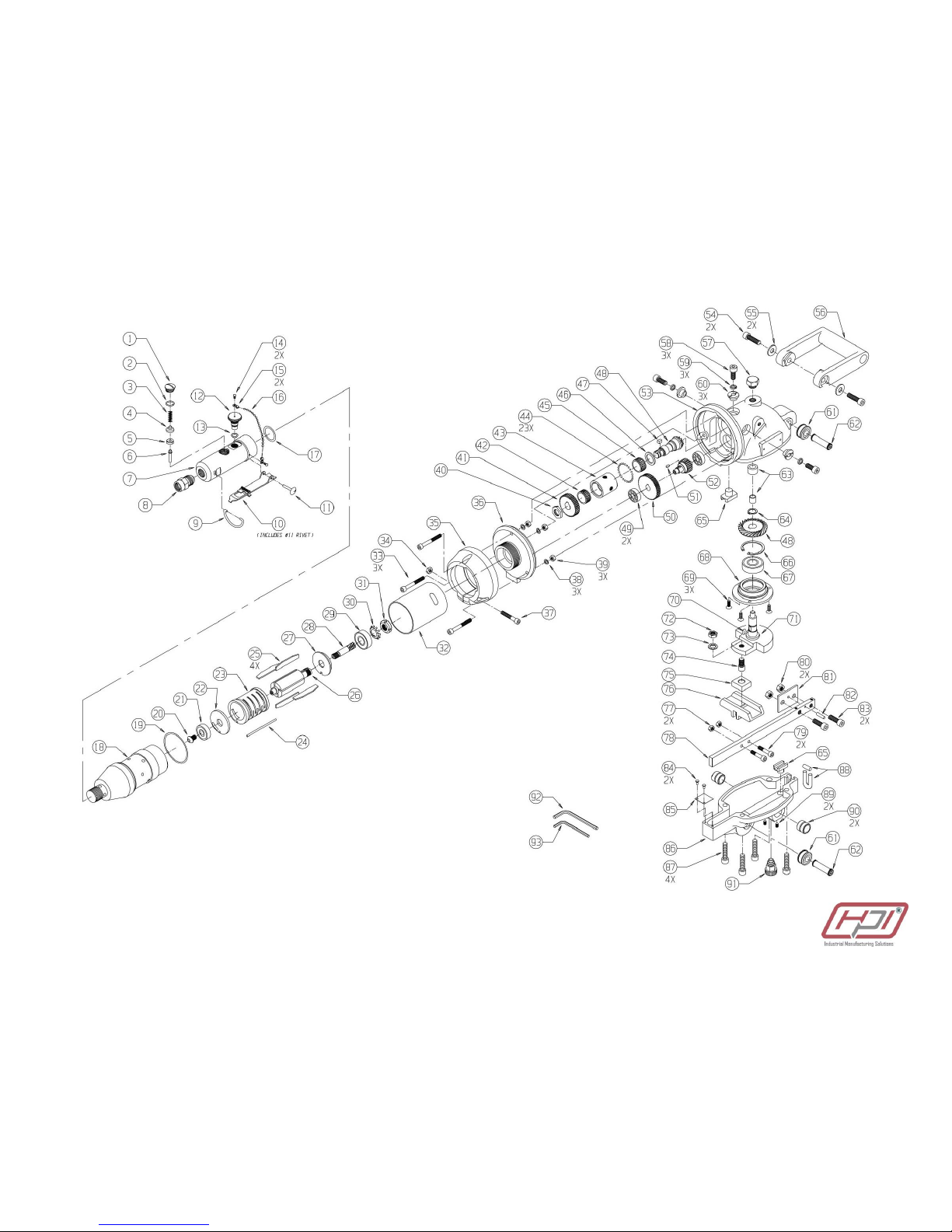

10. Replacement Parts.

-When servicing use only genuine WIDDER®replacement parts from an

authorized distributor.