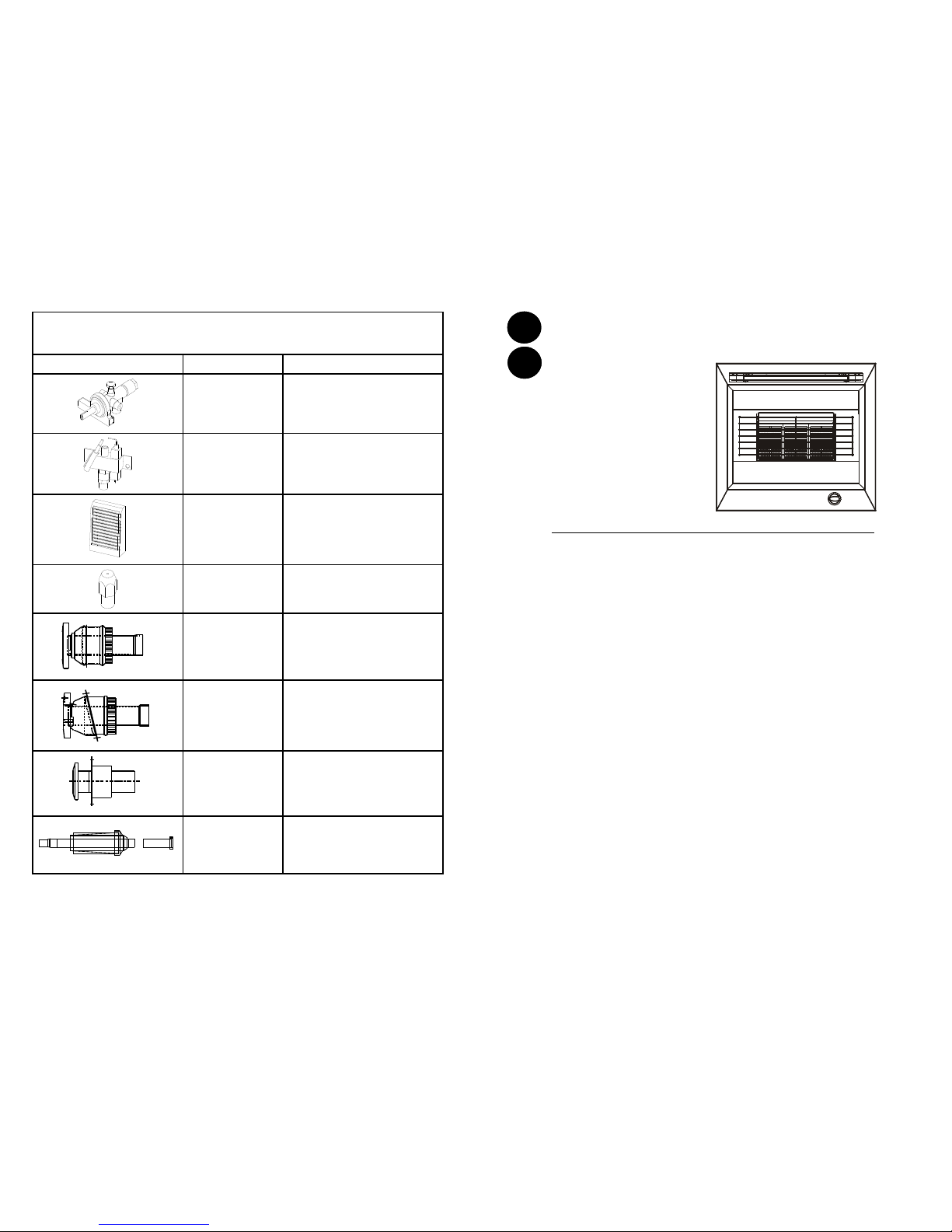

SHORT PARTS LIST

The illustrated short parts list includes part numbers.

When ordering quote gas fire name with part number & description.

Gas Train PART NUMBER DESCRIPTION

W00018

W00166 Control Valve with rotary ignition

(LPG)

Control Valve with rotary ignition

(NG)

W00020

W00170 Oxygen depletion device / pilot

assembly (LPG)

Oxygen depletion device / pilot

assembly (NG)

RA002 Radiant (pack of 3)

W00028

W00167

Burner Injector (LPG)

Burner Injector (NG)

W99901

Straight Terminal with Vent

Plain Finish.

For other finishes please contact

customer services

W99801

Angled Terminal with Vent.

Plain Finish.

For other finishes please contact

customer services

W99600

Straight Terminal Non Vented.

Plain Finish.

For other finishes please contact

customer services

W00213

Terminal with Vent

Pantile Roof

For other finishes please contact

customer services

8

Part Number: W00317 Issue E

GB

IE

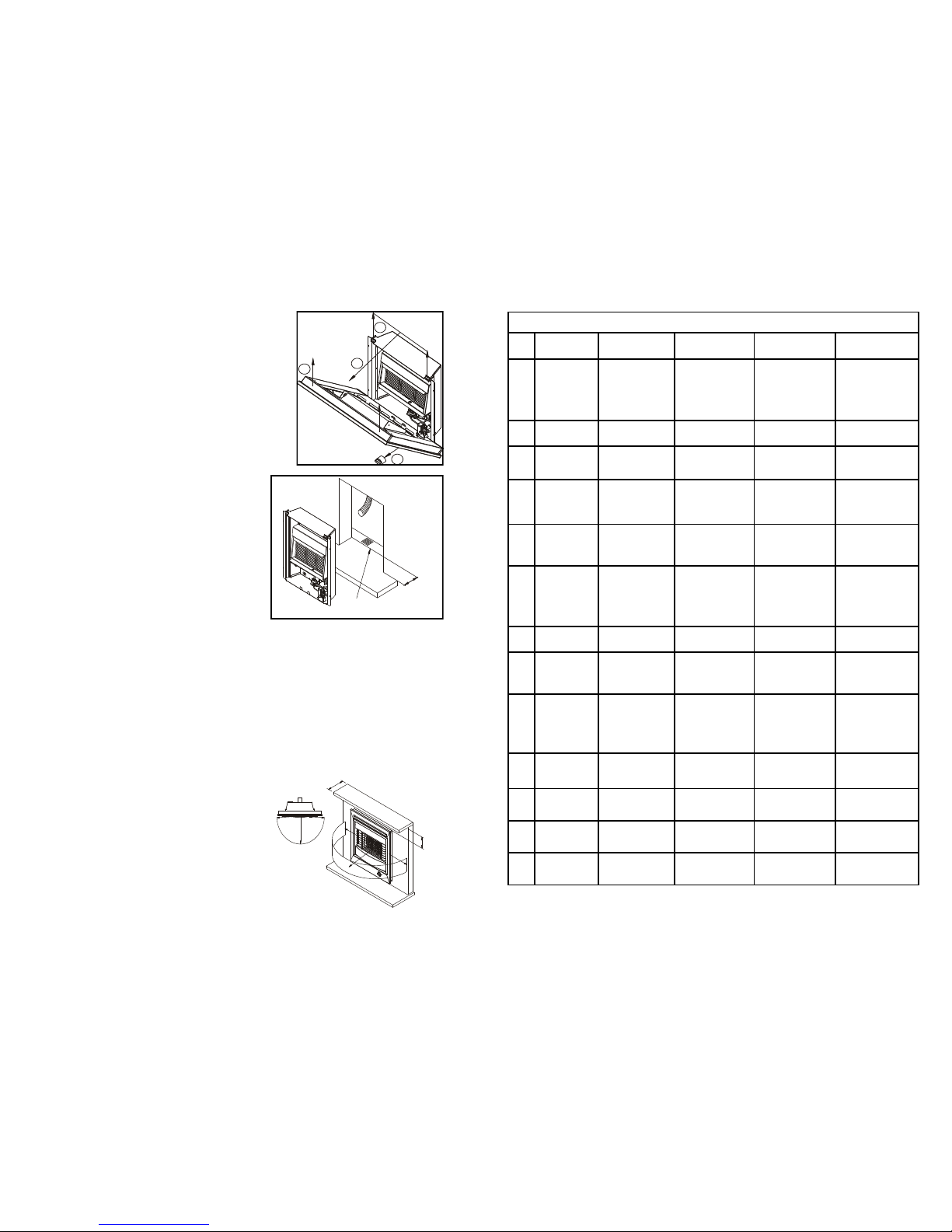

INSTALLATION & MAINTENANCE INSTRUCTIONS

READ THESE INSTRUCTIONS BEFORE INSTALLING OR SERVICING THE FIRE

IMPORTANT: Before installation ensure that the local distribution conditions (identified by

the type of gas and pressure) and the adjustment of the appliance are compatible.

Revo Natural gas version.

The appliance is suitable for use with G20 natural gas at a supply pressure of 20mbar for categories

I2H & I2E and additionally G25 at a supply pressure of 25mbar (pressure couple operates) in the case

of category I2E+& I2L.The following lists all EC member states, which have a suitable gas supply for

each category designation:

I2H:- AT, CH, CZ, DK, ES, FI, GB, GR, IE, IT, NO, PT, SE, EE, LT, LV, SI, SK

I2E:- DE, LU - I2E+:- BE, FR—I2L:- NL

Revo LPG gas version.

The appliance is suitable for use with G30 Butane at a supply pressure of 28-30 mbar and G31

Propane at a supply pressure of 37 mbar for category I 3+. It is also suitable for G30 Butane and

G31 Propane at a supply pressure of 30mbar for I 3B/P

The following lists all EC member states, which have a suitable gas supply for each category

designation:

I 3B/P:- CZ, FI, NL, NO, SE, LT, LV, SI, SK

I 3+:- BE, CH, CZ, ES, FR, GB, IE, IT, PT, EE, CY

It is a legal requirement that all gas appliances are installed by a competent person in accordance

with the Gas Safety Installation and Use Regulations 1994.

Failure to install the appliance as stated can lead to prosecution, it is in your interests

that the law is complied with.

Installation and Ventilation requirements shall be in accordance with these Installation Instructions,

BS EN 1949:2002, BS EN 721:1999, BS5871 and BS EN 1647:1999.

For the Republic of Ireland the installation must be carried out by a competent person and also conform to the relevant pa rts of :

The current edition of IS 813—Domestic Gas Installations

All relevant national and local rules in force

WIDNEY LEISURE LTD.

SAXON BUSINESS PARK, HANBURY ROAD,

STOKE PRIOR, BROMSGROVE,

WORCESTERSHIRE B60 4AD. ENGLAND

TELEPHONE: +44(0)1527 577800

Email: sales@widney-leisure.co.uk Web: www.widney-leisure.co.uk

1

WIDNEY

Revo

Gas Fire

All Model Variants