there is danger of kickback, whenthe cutting disc becomes wedged in the workpiece.

9) Operate the power tool only when the work area to the workpiece is clear of any adjusting tools,

metal chips, etc. Small pieces of metal or other objects that come in contact with the rotating cutting

disc can strike the operator with high speed.

10)Always firmly clamp the workpiece. Do not cut workpieces that are too small to clamp. Otherwise,

the clearance of your hand to the rotating cutting disc is too small.

11)If the cutting disc becomes jammed, switch the machine off and wait until the cutting disc comes to

a complete stop. Never attempt to remove a still running cutting disc from the cut, otherwise there is

danger of kickback. Determine and correct the cause for the jamming.

12)After switching off, do not stop the cutting disc by applying lateral pressure to it. The cutting disc

can become damaged, break or lead to kickback.

13)Do not force the cutting disc into the workpiece and do not apply too much pressure when using

the power tool. Particularly avoid jamming or wedging the cutting disc when working corners or sharp

edges. When the cutting disc is damaged due to abuse, cracks can form that can lead to breakage

without prior warning.

14)Use the cut off grinder only for cutting materials mentioned under “Intended Use”. Otherwise, the

cut off grinder can be subjectto overload.

15)Do not use damaged, out-of-centre or vibrating cutting discs. Damaged cutting discs cause

increased friction, binding of the cutting disc and kickback.

16)Always use cutting discs with correct size and shape (diamond versus round) of arbor holes.

Cutting discs that do not match the mounting hardware of the cut off grinder will run eccentrically,

causing loss of control.

17)Do not attach a saw chain woodcarving blade or toothed saw blade. Such blades create frequent

kickback and loss of control.

18)Observe the operating instructions of the cut-off wheel manufacturer for assembly and use of the

cut-off wheel. Cut-off wheels that do not fit can lead to injury as well as to jamming, breaking or

kickback.

19)Do not use accessories which are not specifically designed and recommended by the tool

manufacturer. Just because the accessory can be attached to your power tool, it does not assure safe

operation.

20)Do not touch the cutting disc after working before it has cooled. The cutting disc becomes very hot

while working.

21)Store the machine in a safe manner when not being used. The storage location must be dry and

lockable. This prevents the machine from storage damage, and from being operated by untrained

persons.

22)Secure the workpiece. A workpiece clamped with clamping devices or in a vice is held more secure

than by hand.

23)Never leave the machine before it has come to a complete stop. Cutting tools that are still running

can cause injuries.

24)Always firmly clamp the piece to be worked. Do not saw workpieces that are too small to clamp.

Otherwise, the clearance of your hand to the rotating saw blade is too small.

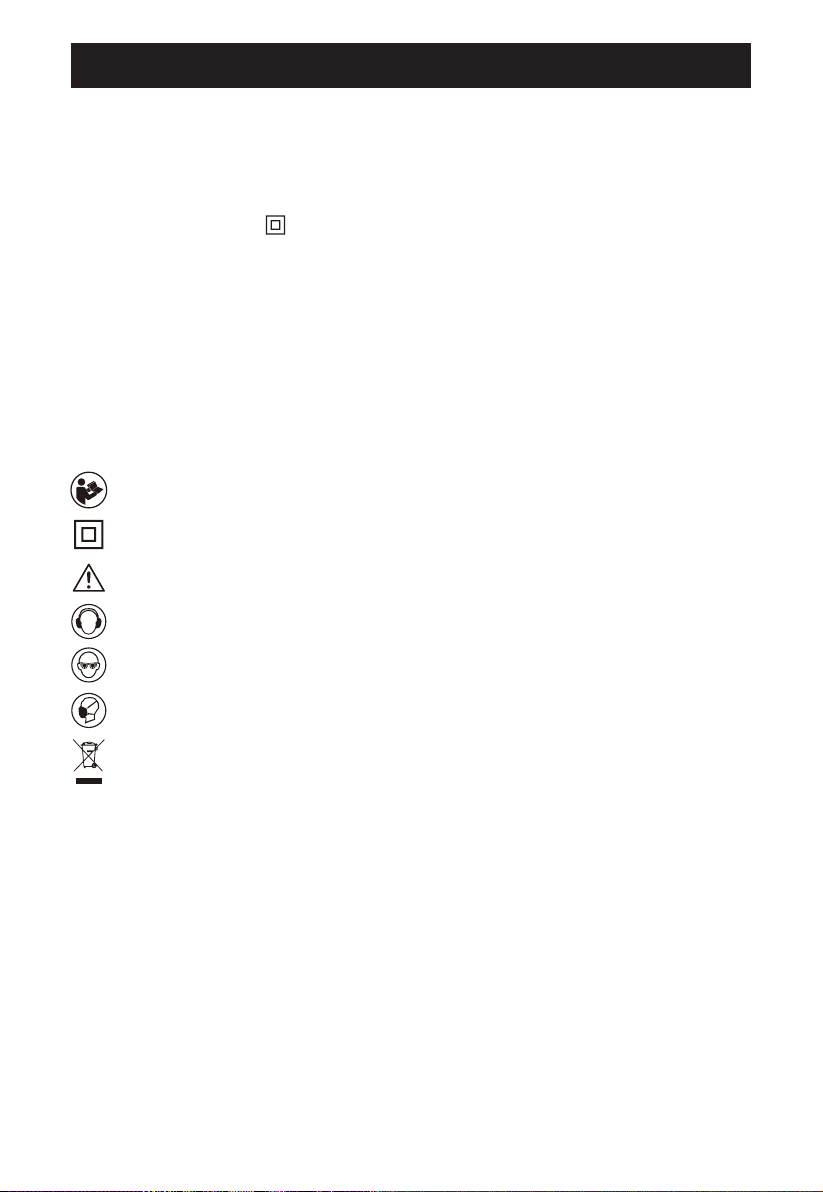

25)Wear ear protectors with power tool. Exposure to noise can cause hearing loss.

26)Wear safety goggles or eye protection when using this power tool. Use a dust mask or respirator

for applications which generate dust.

27)Wear a work apron. Pay attention that other persons are not put at risk from sparking. Remove

8