Wieland gesis LON R-56/0 (RC) User manual

gesis®LON R-56/0 (RC)…

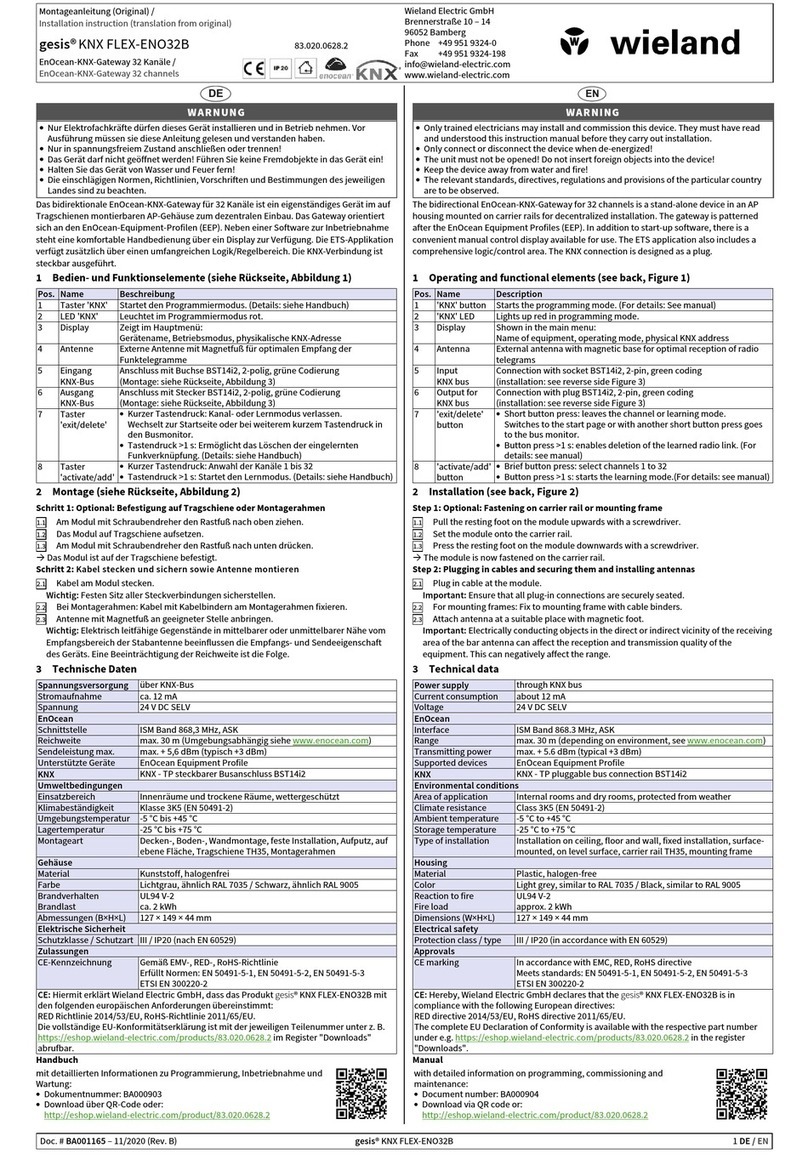

EnOcean®LON Gateway

Manual

Product and Object Description

Doc. no. BA000580

Date: 6/2009 (Rev. A)

© 2008 Wieland Electric GmbH

This document is protected by copyright. The rights established by this remain with Wie-

land Electric GmbH. Reproduction of this document whether in whole or in part is only

permitted within the copyright provisions. Modifications or abridgements of the document

without express written permission of Wieland Electric GmbH are not permitted.

All brands mentioned and when indicated protected by third parties in this document are

subject to, as such unreservedly, the respective valid legal requirements and right of own-

ership of the respective registered owner.

Naming alone does not imply that the trade mark is not protected by third party rights!

Revision Listings

Document BA000579

Revision Date Author / editor

A (first version) 12.2.2009 Th. Nieborg/Th. Kluck

Contents

Wieland Electric | BA000580 | 6/2009 (Rev. A) 3

Contents

1About This Operating Manual.......................................................................... 6

1.1 General Information ................................................................................................... 6

1.2 Symbols and Notation Used ...................................................................................... 6

1.3 Proper Use ................................................................................................................. 7

1.4 Selecting Personnel and Personnel Qualifications..................................................... 8

1.5 Tests and Repairs....................................................................................................... 8

1.6 Hazards due to Electrical Energy ............................................................................... 8

2The LON Bus System....................................................................................... 9

2.1 Technology................................................................................................................. 9

2.2 Topology .................................................................................................................... 9

2.3 Addressing ................................................................................................................. 9

2.4 Communication........................................................................................................ 10

2.5 Software................................................................................................................... 10

2.6 Installation of the LNS Plug-In ................................................................................. 10

2.6.1 System requirements ............................................................................................... 10

2.6.2 Device and parameter description files (SDRF, UDRF)............................................ 10

2.6.3 Availability ................................................................................................................ 10

2.6.4 Installation................................................................................................................ 11

2.6.5 Installation routine ................................................................................................... 11

2.6.6 Registration in the Windows registry ...................................................................... 11

3gesis LON R: System Overview ..................................................................... 12

3.1 Selection of an Application Program ....................................................................... 12

3.2 Modules With No Mounting Feet ............................................................................ 12

3.3 Place of Installation .................................................................................................. 12

4gesis LON R-56/0 (RC) ................................................................................... 13

4.1 Device Description ................................................................................................... 13

4.2 Function ................................................................................................................... 13

4.3 Dimensions, Connections and Function Elements .................................................. 14

4.4 Terminal Assignment ............................................................................................... 15

4.5 Technical Data.......................................................................................................... 16

4.6 Installation................................................................................................................ 17

4.6.1 Assembly (83.020.0320.0) ....................................................................................... 17

4.6.2 Dismantling (83.020.0320.0).................................................................................... 17

4.6.3 Replacing modules (83.020.0320.1) ........................................................................ 17

4.7 Accessories .............................................................................................................. 17

5Installation of the LNS Plug-In....................................................................... 18

6Teach-in of the sensors ................................................................................. 19

7Parameterisation ........................................................................................... 20

7.1 General ..................................................................................................................... 20

7.2 NodeObject .............................................................................................................. 21

7.3 EnOcean-Objekt ....................................................................................................... 22

7.4 Panel......................................................................................................................... 24

7.5 Parameterisation of individual sensors .................................................................... 25

7.5.1 Button / Switch transmission element..................................................................... 26

7.5.1.1 Switch / Button transmission element (Switch / Button value).............................. 26

7.5.1.2 Switch / Button transmission element (presence information) .............................. 29

Contents

4 Wieland Electric | BA000580 | 6/2009 (Rev. A)

7.5.1.3 Switch / Button transmission element (scene number) ......................................... 30

7.5.2 Window contact ....................................................................................................... 31

7.5.3 1-byte sensor ............................................................................................................ 31

7.5.3.1 1-byte sensor (temperature value)........................................................................... 32

7.5.3.2 1-byte sensor (brightness value) .............................................................................. 33

7.5.3.3 1-byte sensor (other)................................................................................................. 33

7.5.4 4-byte sensor ............................................................................................................ 34

7.5.4.1 4-byte sensor (temperature value)........................................................................... 34

7.5.4.2 4-byte sensor (brightness value) .............................................................................. 35

7.5.4.3 4-byte sensor (other)................................................................................................. 35

7.5.5 Alarm transmitter...................................................................................................... 35

7.5.6 Window handle ........................................................................................................ 36

8Operation....................................................................................................... 38

8.1 Teach-in of transmitters (Learn; e.g. button)............................................................ 38

8.2 Deletion of assignments (Clear) ............................................................................... 38

8.2.1 Variant 1: Delete a single ID ..................................................................................... 38

8.2.2 Variant 2: Delete all IDs from one channel............................................................... 38

8.2.3 Variant 3: Delete all IDs from the gateway (restore factory settings) ...................... 39

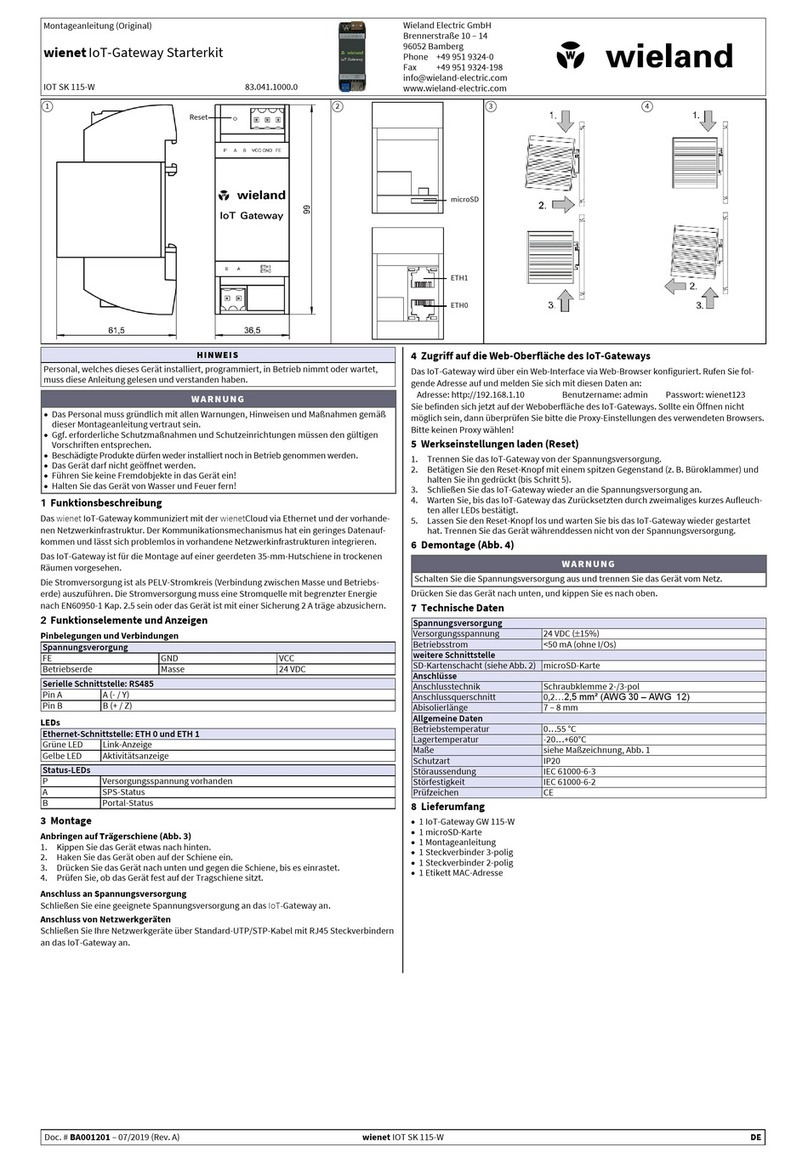

9Power supply gesis EIB RM-PS ..................................................................... 40

9.1 Device Description ................................................................................................... 40

9.2 Function.................................................................................................................... 40

9.3 Dimensions, Connections and Function Elements................................................... 41

9.4 Terminal Assignment................................................................................................ 41

9.5 Technical Data .......................................................................................................... 41

9.6 Installation ................................................................................................................ 42

9.6.1 Assembly (83.020.0401.0)........................................................................................ 42

9.6.2 Disassembly (83.020.0401.0) ................................................................................... 42

9.6.3 Replacing modules (83.020.0401.1)......................................................................... 43

10 Power supply gesis RM-PS 12/5.................................................................... 44

10.1 Device Description ................................................................................................... 44

10.2 Function.................................................................................................................... 44

10.3 Dimensions, Connections and Function Elements................................................... 45

10.4 Terminal Assignment:............................................................................................... 45

10.5 Technical Data .......................................................................................................... 46

10.6 Installation ................................................................................................................ 47

10.6.1 Assembly (83.020.0421.0)........................................................................................ 47

10.6.2 Disassembly (83.020.0421.0) ................................................................................... 47

10.6.3 Replacing modules (83.020.0421.1)......................................................................... 47

About This Operating Manual

Wieland Electric | BA000580 | 6/2009 (Rev. A) 5

Dear customer,

Congratulations on purchasing your new components of the gesis LON R building installa-

tion system. You are now the owner of a product with the LON technology which provides

you with a user-friendly means of dealing with numerous building control tasks.

Please familiarise yourself with the descriptions in this manual. It will provide you with

all the information and assistance required for faultless operation of your gesis system.

Should you have additional questions or require further assistance, please contact our

team of specialists using the contact information below and they will be happy to help

you.

Wieland Electric GmbH

Brennerstraße 10-14

96052 Bamberg, Germany

Technical customer service hotline (for technical issues concerning accessories, functions,

product features and possible applications):

Tel.: +49 (0) 9 51 / 93 24-9 96

Fax: +49 (0) 9 51 / 93 26-9 96

Email: BIT.TS@wieland-electric.com

Sales hotline (for information about availability, lead times and prices):

Tel.: +49 (0) 9 51 / 93 24-9 90

Email: BIT.info@wieland-electric.com

About This Operating Manual

6 Wieland Electric | BA000580 | 6/2009 (Rev. A)

1About This Operating Manual

1.1 General Information

This operating manual will provide you with support for installing and parameterising gesis

LON R modules. In it, you will find information about how devices are programmed, con-

figured and parameterised.

This operating manual contains the information required for proper usage of the prod-

uct it describes. It describes the gesis LON R component, its technical features, conditions

of use, boundary conditions and parameterisation. Installation and connection with the

gesis CON connector system are described in the document entitled "System Handling

Information" (item no. 0060.2), which is available separately.

gesis systems must only be installed by trained personnel and the applicable regula-

tions observed while doing so. For this reason, the gesis LON R system manual is aimed

at:

•Persons responsible for configuring, parameterising and activating LON systems

•System integrators

•Electricians

Specific prerequisites are:

•Basic knowledge of LON bus technology

•Basic knowledge of building installation systems

•Programming knowledge relating to LON objects

1.2 Symbols and Notation Used

The following are used in this operating manual:

A notice informs you about special features of a device or a software function. "Notice"

also indicates information that is directly or indirectly related to the safety of personnel or

property. It is not used for hazards or hazardous situations.

The names of software menus, submenus, options and commands, selection fields and

windows are shown in bold. Example: Click on Edit in the File menu.

Keys and key combinations are shown in UPPERCASE. Key combinations, i.e. keys which

have to be pressed simultaneously, are linked with a "+". Keys which have to be pressed

one after the other are linked with a "–". Example: Press CTRL+ALT+DEL (simultaneously).

Press F12–2 (one after the other). The naming of the keys refers to standard keyboards

which are labelled in the language of the user country. It is possible you are using a key-

board with other key labelling, e.g. in the German language.

Objects, variables, program code and parameters are identified with typewriter font.

NOTICE

Menus and

Commands

Keys

Objects and

variables

About This Operating Manual

Wieland Electric | BA000580 | 6/2009 (Rev. A) 7

This operating manual uses various safety notices that are assigned according to the sever-

ity of a potential hazard:

"Danger" indicates an imminently hazardous situation or state which, if not avoided, will

result in serious injuries or death. The use of "Danger" is limited to the most extreme situa-

tions.

"Warning" indicates a potentially hazardous situation or state which, if not avoided, canre-

sult in serious injuries or death.

"Caution" indicates a potentially hazardous situation or state which, if not avoided, can

result in minor or moderate injuries. "Caution" is also used to warn against unsafe prac-

tices or obvious misuse, as well as for situations which may result in material damage or

personal injury.

"Danger" or "Warning" are basically used for cases which present a risk to life or limb.

Damage to property only falls into these categories if there is also a risk of personal injury

that corresponds to these levels.

1.3 Proper Use

•Electrical installations, commissioning and maintenance work, as well as configuring and

programming work, must only be performed by qualified electricians with relevant acci-

dent prevention training, and in compliance with the applicable regulations.

•Safety precautions and safety devices must comply with the applicable regulations.

•Compliance with the required regulations is achieved when the devices are correctly

processed in order to create an end product.

•Damaged products must neither be installed nor put into operation.

•On account of the class and degree of protection, all devices must be installed in a gesis

distribution box (gesis RAN) or similar housing.

•Due to their holding equipment, devices without locking feet may only be installed in a

gesis RAN housing provided by Wieland Electric.

•A power supply from the gesis RM series of devices is required for operating the basic

module. If a power supply other than the gesis product intended for this purpose is used,

Wieland Electric GmbH cannot guarantee that faultless operation will take place.

•When looping through the voltages, the maximum current of 16 A must not be ex-

ceeded.

The control system must only be used when in proper working condition, as well as ac-

cording to its prescribed usage, with due regard given to safety, awareness of any hazards

and following the instructions contained in the operating manual. Reliable and safe opera-

tion requires proper transport, storage and installation, as well as careful operation. In

particular, safety-related faults must be rectified immediately by a professional.

The control systems are exclusively intended for controlling building equipment. Other

applications, or use beyond this scope, are considered to be improper. The manufacturer

assumes no responsibility for any damage resulting from usage of this nature.

In order to use the control systems as prescribed, the instructions outlined in this oper-

ating manual must be followed for mechanical and electrical installation procedures, as

well as for commissioning and operation of the systems.

DANGER

WARNING

CAUTION

WARNING

NOTICE

About This Operating Manual

8 Wieland Electric | BA000580 | 6/2009 (Rev. A)

1.4 Selecting Personnel and Personnel Qualifications

•Electrical installations, commissioning and maintenance work, as well and configuring

and programming work, must only be performed by trained, qualified electricians with

relevant accident prevention training, and in compliance with the applicable regulations.

•Configuring and programming personnel must be familiar with the safety concepts in-

volved in building installation technology.

•Operating personnel must be trained in handling the control system and familiar with the

operating instructions.

•Installation, commissioning and maintenance personnel must have a training back-

ground which authorises them to carry out work on the control system.

1.5 Tests and Repairs

When measurement or testing procedures are being performed on the active device, the

specifications and implementation guidelines of the relevant accident prevention regula-

tions must be observed. Only suitable tools may be used for this.

Repairs to control components must only be carried out by the manufacturer.

Unauthorised opening and improper intervention or repairs can result in material damage

or bodily harm.

In the event of a fault, send devices back to:

Wieland Electric GmbH

Abteilung (Department) TQM 3

Brennerstraße 10-14

96052 Bamberg, Germany

1.6 Hazards due to Electrical Energy

The user must ensure that unauthorised and improper interventions are prevented. Per-

sonnel must be familiar with all sources of hazards and all procedures involved for the

commissioning. This includes both data contained in the gesis "System Handling Informa-

tion" document (item no. 0060.2) and device packaging inserts as well as the relevant

content from this manual.

WARNING

CAUTION

The LON Bus System

Wieland Electric | BA000580 | 6/2009 (Rev. A) 9

2The LON Bus System

2.1 Technology

LON systems are based on an "installation bus": this refers to the cable which links all the

devices that are connected and transfers signals between all the bus nodes.

LON is a decentralised bus system. A central unit is not required since each node (bus

device) has its own intelligence. Software is used to download all the required parameters

to the individual devices via the bus. Different transfer media are available within the LON.

All Wieland LON devices use twisted pair (TP) 2-wire bus technology and a TP/FT-10

transceiver with external power supply. A separate cable is used, which is laid when the

standard electrical installation takes place and provides the medium for transporting status

messages or switching commands for communication purposes.

In larger LON systems, the subnets are logically linked and electrically isolated from each

other by means of routers. The routers ensure that the telegram load on the coupled sub-

nets does not become too great. They prevent telegrams that are only required in particu-

lar areas from entering other areas, thereby reducing the bus load. The LON is an event-

controlled bus system, which means that telegrams are only created when they are actu-

ally needed.

2.2 Topology

Each bus connection represents a node, regardless of whether this is concerned with a

straightforward button or complex visualisation.

The nodes in each system are divided into sensors (e.g. buttons, temperature sensors),

actuators (e.g. switching outputs, shutter outputs) and system devices (e.g. routers, power

supplies).

The smallest unit in the LON system is a subnet. A subnet can link up to 127 nodes.

Routers enable up to 255 subnets to be connected to form a domain (a network). This

means that networks with more than 32,000 nodes in a domain can be implemented. In

the case of extremely complex installations, special couplers can be used to interconnect

several domains.

2.3 Addressing

Unique "addresses" are used for identifying and addressing specific bus nodes. The LON

system uses two address types:

Neuron ID

The Neuron ID is a 48 bit identifier that is unique worldwide (similar to an Ethernet MAC

address) and which is assigned to every LON chip during manufacture. It enables any node

to be unambiguously identified at any time. This allows separate LON networks to be

automatically combined at a later date in order to create one single network, for example.

Subnet/Node ID

The subnet/node ID is assigned to each node during commissioning. It unambiguously

defines each node. Since this address is based on the subnet structure, the bus system

itself remains clear, right up to the final extension stage. In addition, the subnet/node ID

ensures that the commissioning engineer has enough leeway to take building structures

The LON Bus System

10 Wieland Electric | BA000580 | 6/2009 (Rev. A)

into account as well. Each device can be addressed in such a way that it can easily be

assigned to existing building structures (e.g. "West building, 1st floor, North side").

2.4 Communication

The LONTALK protocol is used for communication between nodes. Logical links are cre-

ated between buttons, controllers and actuators, for example, by means of "bindings".

These links can be established within the same subnet or via multiple routers. If the latter

is the case, the required filter tables in the routers are created and stored automatically.

Special routers can also be used to interconnect individual subnets via TCP/IP links. This

allows an existing Ethernet infrastructure to serve as a backbone.

2.5 Software

A variety of software tools is available for planning, commissioning and documenting a

LON system. This means that, whatever the requirements of the project or the level of

training undergone by the commissioning engineer, there will always be an appropriate

tool.

The LNS has established itself as the common network operating system and is used by

all relevant tools. Subnet/node IDs, bindings, parameters, etc. can be defined and changed

via LNS not only for each device, but also for the system as a whole.

The manufacturers provide specific data for the devices used in the system free of

charge, in the form of application files, and input it into the LNS. As well as the standard

configuration options provided by the commissioning tools, the majority of manufacturers

also provide configuration tools (plug-ins) free of charge, which are integrated in the soft-

ware tool, to make commissioning easier.

LNS plug-ins are available free of charge for all Wieland LON devices and can be used in

an LNS environment of version 3 or higher.

2.6 Installation of the LNS Plug-In

2.6.1 System requirements

•PC/laptop with an LNS installation tool installed and a suitable interface for connecting to

the LON system

•LNS version 3.x or higher with all available service packs

•Standard Device Resource Files (SDRF) version 12 or higher (available free of charge at

www.lonmark.org)

2.6.2 Device and parameter description files (SDRF, UDRF)

Standard Device Resource Files (SDRF) version 12 or higher must be installed before in-

stallation of the plug-in. The user-defined description files (UDRF) that are required to dis-

play Wieland-specific parameters correctly are automatically copied and initialised when

the Wieland plug-in is installed.

2.6.3 Availability

The Wieland LNS plug-in for the gesis LON R series of devices can be downloaded free of

charge from the downloads area of the Wieland website (www.gesis.com).

It is recommended to download the current version before each new project.

The LON Bus System

Wieland Electric | BA000580 | 6/2009 (Rev. A) 11

2.6.4 Installation

To install the plug-in, please launch the "setup.exe" file and follow the on-screen instruc-

tions.

2.6.5 Installation routine

The installation routine automatically performs all the steps required to install the plug-in,

register the Wieland parameter descriptions( UDRFs) and copy the device templates. The

following default directories within the LonWorks basic directory (usually C:\LonWorks\)

are used:

•The plug-in is installed in ..\PlugIns\Wieland Electric\WLD_GESISRC\

•The UDRFs are stored under ..\types\User\Wieland Electric\

•The device templates are stored under ..\import\Wieland Electric\

Following successful installation, a new program directory called "Plug-In for gesis LON R

Devices" is created in the Windows Start menu, which can also be used for direct access

to the manual (this document).

2.6.6 Registration in the Windows registry

The installation routine automatically enters the plug-in in the Windows registry. If the

entry is not made automatically, it must be done manually before the LNS commissioning

tool can be used. To do this, launch one instance of the plug-in directly via the Windows

Start menu and select the "Register" button. The plug-in can then be registered using the

procedure for individual LON projects, which is specific to each commissioning tool.

If the Wieland plug-in needs to be removed from the Windows registry, please launch

the plug-in directly once again via the Windows Start menu and select "Unregister".

gesis LON R: System Overview

12 Wieland Electric | BA000580 | 6/2009 (Rev. A)

3gesis LON R: System Overview

3.1 Selection of an Application Program

This manual refers to the application program with the file name WiRcGate1x.

3.2 Modules With No Mounting Feet

In order to achieve a minimum installation height of approximately 55 mm when installing

modules in the gesis RAN pluggable distribution box, they are also manufactured without

feet. These modules are installed in the gesis RAN in the factory using special equipment.

3.3 Place of Installation

The modules must be installed in a gesis RAN or similar housing. If a gesis RAN distribu-

tion box is used, the modules are installed by Wieland and wired to gesis CON series con-

nectors. The distribution box is designed and manufactured in accordance with customer

requirements, meaning it can be adapted to almost any conditions. The system/customer-

specific planning and design of the distribution box also extends to labelling of the inputs

and outputs. External connections are established using the gesis CON connector system.

As terminal blocks, transformers and other similar devices can also be installed in these

distribution boxes, this allows complete room functions to be created and efficiently inte-

grated into the pluggable electrical installation.

gesis LON R-56/0 (RC)

Wieland Electric | BA000580 | 6/2009 (Rev. A) 13

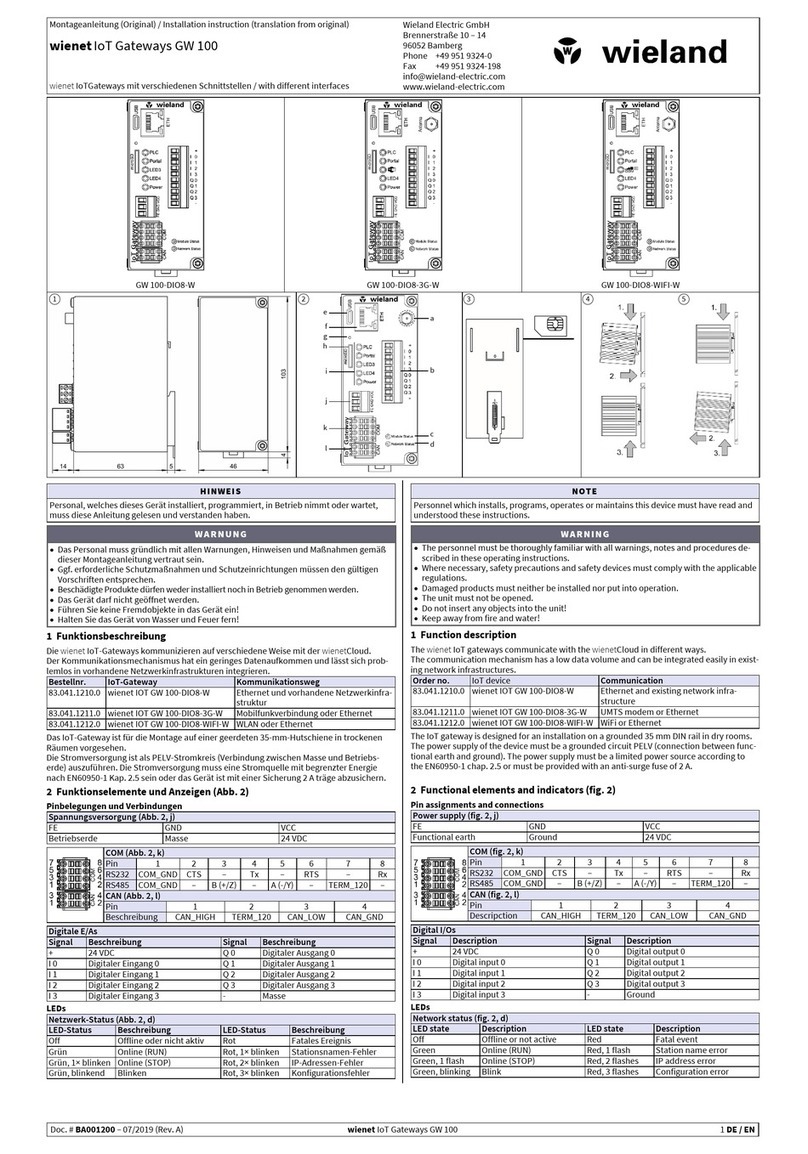

4gesis LON R-56/0 (RC)

4.1 Device Description

Designation

Type/Art. No.

Device type

Design type

Basic module, LON coupling

gesis LON R-56/0 (RC) 83.020.0320.0

gesis LON R-56/0 (RC) B 83.020.0320.1

Basic module

Device with screw clamp terminals for

installation in a gesis RAN distribution

box

Please ensure that you pay strict attention to the warnings and notes in the sections enti-

tled "Proper Use" and "Selecting Personnel and Personnel Qualifications" in Chapter 1.

4.2 Function

The gateway receives EnOcean telegrams and converts these into LON network variables

(NVs). The gateway interprets the EnOcean telegrams ORG5 (RPS Type 1), ORG6 (1BS) and

ORG7 (4BS), like those for example from EnOcean sensors, the Wieland alarm transmitter

or the EnOcean window contact. The identification number (ID) of the sender is transmit-

ted with these telegrams. Each sender has a unique ID which is checked by the gateway

during receipt of a telegram.

Up to 170 sending channels can be stored on the input side and distributed to the 56 LON

NVs.

The gateway needs an external power supply and an antenna for operation.

NOTICE

NOTICE

gesis LON R-56/0 (RC)

14 Wieland Electric | BA000580 | 6/2009 (Rev. A)

4.3 Dimensions, Connections and Function Elements

13

10

8

6

2

1

+

2

2

3

B

4

3

-

6

55

6

W

1

B

2

4

1

ID

11

12

7

9

5

4

3

1

2

8

a b

8

4

4

4

a b

ID a

a

+

2

+ - All

ID12V DC

0

9

3

>1s

0

9

3

Channel

4

A

2

A

3

CLR >10s

ID

>1s

LON

Test

1

b

3

7

1

Ch.

a

7

1

FTT-10A

+

b

+ CLR >3s

b

LON R-56/0 (RC)

Learn

EnOcean

83.020.0320.0

wieland

Service

LON

56x Input RC

gesis

Clear

1 LON bus connection

2 Service Pin according to LONMARK

3 Service LED (red): Light and flashing pattern according to LONMARK

4 Channel selector switch, tens position

5 Channel selector switch, units position

Example: Channel selector switch 4 on "1" and switch 5 on "7" produces channel 17.

Valid settings are 0-55 (teach, delete and test functions), 99 (deletion of all assignments

in the "Clear" mode). Other channel numbers have no function. Any channel can be set

in operation.

6 Button "Test"

Set the channel selector switches 4 and 5 to the channel to be tested. If you now press

the Test button, you initiate a reaction on the channels 0-55 in accordance with the

parameterisation.

7 Button "Clear" (delete)

8 LED "Clear" (red)

Flashing: receipt of a telegram with unknown ID

Flashing: Clear mode active

Fast flashing:Warning about deletion of all assignments

9 Button "Learn" (Teach-in)

10 LED "Teach-in" (green)

Flashing: receipt of a telegram with known ID from

not taught-in channels

Flashing: Teach-in mode active

11 Power supply 12.5 V DC

12 SMA antenna socket

13 Locking slide (only for 83.020.0320.0)

gesis LON R-56/0 (RC)

Wieland Electric | BA000580 | 6/2009 (Rev. A) 15

4.4 Terminal Assignment

X1: Connection and routing of the LON bus; terminals 1/2 and 3/4 are bridged internally

1—LON B

2—LON A

3—LON B

4—LON A

X2: Connection and routing of the operating voltage; terminals 1/2 and 3/4 are bridged

internally

1—Operating voltage 12.5 V DC SELV +

2—Operating voltage 12.5 V DC SELV +

3—Operating voltage 12.5 V DC SELV −

4—Operating voltage 12.5 V DC SELV −

gesis LON R-56/0 (RC)

16 Wieland Electric | BA000580 | 6/2009 (Rev. A)

4.5 Technical Data

Wireless technology

Technology Use of the EnOcean protocol

Frequency band 868.3 MHz

Range

– Line of sight Typically 30 m in corridors; up to 100 m in halls

– Plasterboards / wood Typically 30 m through max. five walls

– Brick/aerated concrete walls Typically 20 m through max. three walls

– Reinforced concrete

walls/ceilings:

Typically 10 m through max. one ceiling

Significant restriction of the range (up to shielding

of the radio signal):

Insulation wool on metal foil, suspended ceilings or elevated floors and

panels made of metal or carbon fibre, lead glass or glass with metal coating,

steel furniture, mounting of the switch on metal. Fire protection walls, lift shafts.

Stairways, supply and similar areas should be sealed off. The angle at which the radio

signals meet a wall also has a role to play. The effective wall thickness and, therefore, the

signal attenuation will vary depending on the angle. Where possible, the signals should

meet a wall at a slight angle; wall alcoves should be avoided.

Bus connection

Connection type

Connection cross-section

Screw clamp terminals

0.14 to 4 mm², single-core

0.14 to 2.5 mm², finely stranded

6.5 mm stripped in each case

Operating voltage 12,5 V DC ( -15 %/+10%) SELV

Rated current 80 mA

Antenna connection SMA socket

Impedance 50 Ω

Antenna suitable for 868.3 MHz; the

Wieland antenna is recommended; see ordering instruc-

tions

Electrical safety

Protection class none (depends on subsequent work)

Degree of protection IP 00; according to installation in gesis distribution box:

min IP20

Degree of soiling 2

Surge voltage category III

EMC requirements conforms to EN 61000-6-2/-6-3 and EN 50090-2-2

Operating conditions

Field of application For installation in gesis distribution boxes, which are in

turn intended for fixed installation in interior and dry areas

Temperature ranges

– Operating environment −5 °C to 45 °C

– Storage −25 °C to +70 °C

relative humidity 5% - 93%

Moisture condensation not permitted

Climate resistance according to EN 50090-2-2

General data

Housing material Plastic, halogen and phosphorous-free

Housing colour black

Behaviour in fire V2 according to UL 94 (housing)

Thermal load approx. 3 kWh

Approval LONMARK-compliant

Weight approx. 110 g

Dimensions see "Dimensions, Connections and Function Elements"

CE marking according to EMC Directive (residential and functional

buildings), Low Voltage Directive

gesis LON R-56/0 (RC)

Wieland Electric | BA000580 | 6/2009 (Rev. A) 17

4.6 Installation

•The flat cable must only be connected or disconnected when the power is off.

•When connecting and disconnecting the flat cable, you must ensure that no power is

being supplied to the basic module.

•The maximum length of the flat cable (120 mm) must not be exceeded.

•When looping through the voltages, the maximum current of 16 A must not be ex-

ceeded.

4.6.1 Assembly (83.020.0320.0)

1. Latch the module onto the DIN rail.

2. Connect the power supply and the LON bus.

3. Connect the antenna to the SMA socket.

4.6.2 Dismantling (83.020.0320.0)

4. Disconnect the module from the power supply.

5. Undo the connections at the terminal strips.

6. Insert a screwdriver into the locking slide and release the module from the DIN rail.

4.6.3 Replacing modules (83.020.0320.1)

7. Disconnect the power supply from the module.

8. Remove the flat cable from the front of the device.

9. Undo the connections at the terminal strips.

10. Slacken the knurled-head screws in the gesis RAN housing (see Fig.

11. Push the slide towards the modules as shown

("1": slide closed; "2": slide open).

Notice: This will release all the modules.

12. Replace the relevant module.

13. Reattach the modules by following steps 1 to 5 in reverse order.

4.7 Accessories

Power supply gesis RM-PS 83.020.0401.0

Power supply gesis RM-PS B 83.020.0401.1

Antenna 83.020.0503.0

CAUTION

Installation of the LNS Plug-In

18 Wieland Electric | BA000580 | 6/2009 (Rev. A)

5Installation of the LNS Plug-In

The LNS Plug-In can be installed using the WLD_GESISRC_Setup.exe installation file. The

requirements are an existing LNS version 3.08 or higher and installed Standard Device

Resource Files (SDRFs) of version 12 or higher (available at www.lonmark.org).

The setup program installs the LNS Plug-In, the Wieland-specific Device Resource Files

(UDRFs) and the device template (XIF and APB in the directory:

...\LonWorks\import\Wieland Electric\WLD_GESISRC). It registers the plug-in in the registry

automatically. A system restart may be required after the installation of the plug-in.

After successful installation, the plug-in can be registered in the LNS integration tool. In

doing so, the device template is created automatically.

Teach-in of the sensors

Wieland Electric | BA000580 | 6/2009 (Rev. A) 19

6Teach-in of the sensors

The teach-in of the sensors can be performed at any time. However, it is recommended to

not teach in the sensors until after the LON commissioning. A detailed description for this

can be found in the technical documentation for this module (at the end of this document).

Parameterisation

20 Wieland Electric | BA000580 | 6/2009 (Rev. A)

7Parameterisation

7.1 General

Wieland Electric recommends the parameterisation using the LNS Plug-In; however it can

also be performed directly in the LNS Tool.

The application is implemented with a static XIF file with dynamic network variables.

The module, together with order number, designation and type, are displayed in the

start window:

If changes have been made to the parameterisation, these must be stored in the LNS using

the "Save in LNS* button (top left, with red arrow).

Until the changes are saved, these are highlighted by being displayed in red. A change

counter in the top right area of the LNS Plug-In shows the storage still remaining to be

done.

The buttons "Store in LNS" and "Load from LNS" are visible on every screen and can be

used directly. The individual parameterisation areas are selected by clicking in the tree

structure on the left.

Start window

Table of contents

Other Wieland Gateway manuals

Popular Gateway manuals by other brands

TelcoBridges

TelcoBridges 3200 Series Gateway Standalone installation guide

OpenVox

OpenVox SWG20-4S Series user manual

ZyXEL Communications

ZyXEL Communications Unified Security Gateway ZyWALL 300 user guide

PULSE+

PULSE+ ROIP-400 Operation manual

Cooper & Hunter

Cooper & Hunter Modbus Mini Installation & owner's manual

NetComm Wireless

NetComm Wireless NF18ACV user guide