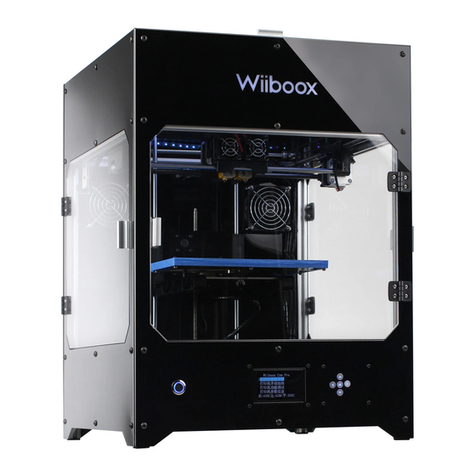

Wiiboox LIGHT User manual

WIIBOOX LIGHT-3D Printer User Guide

WIIBOOX LIGHT-3D 打印机用户指南

Page 1 of 16

WIIBOOX LIGHT

3D 打印机用户指南

3D Printers User Guide

Content

Introduce 介绍.............................................................................................................................................................................. 2

General safety information 一般安全信息.................................................................................................................................. 2

Use Notice 使用注意事项........................................................................................................................................................... 2

Workplace health and safety 工作场所健康与安全....................................................................................................................2

Electric Safety 电气安全.............................................................................................................................................................3

Safety of Machinery 机械安全................................................................................................................................................... 3

Burn Risk 烧伤风险..................................................................................................................................................................... 3

Safe Storage 安全储存................................................................................................................................................................. 3

About "Wiibox Linght"有关“Wiibox Linght”............................................................................................................................. 3

How does it work?如何运作?....................................................................................................................................................3

产品规格 Product Standard..........................................................................................................................................................4

建议环境 Suggestion environment.............................................................................................................................................. 4

包装清单 Pack list........................................................................................................................................................................4

主要部件 Main part......................................................................................................................................................................5

3D 打印技术词汇 3D Printing Technology Term...................................................................................................................... 5

首次使用准备工作 Preparation Work for First Use....................................................................................................................6

切片支撑软件“wiibooxslicer”使用 Use of Slice Support Software "wiibooxslicer"................................................................ 8

启动打印 Start Printing.............................................................................................................................................................. 11

后处理 Post—process.................................................................................................................................................................12

关于打印失败的处理 Treatment of Print Failures....................................................................................................................14

更换材料 Change the material................................................................................................................................................... 14

可用材料 Available Materials.................................................................................................................................................... 15

基本维护和服务工作 Basic Maintenance and Service Work...................................................................................................15

支持和故障排除 Support and Troubleshooting........................................................................................................................ 15

回收 Recovery............................................................................................................................................................................ 16

WIIBOOX LIGHT-3D Printer User Guide

WIIBOOX LIGHT-3D 打印机用户指南

Page 2 of 16

Introduce 介绍

1.在首次操作 “Wiibox Linght”之前,请仔细阅读本用户指南

2.用户指南包括有关“Wiibox Linght”,安全和保护的基本信息准则,以及为第一次使用过程准备机器和基本维护工作,

如果不仔细阅读,可能会导致财产损失,设备故障或 3D 打印质量下降。

3.确保每个 3D 打印机使用者都知道,完全理解并遵循说明本用户指南中提供的操作方式使用。

4.制造商尽一切努力确保产品在运输过程中安全、安装、使用、储存和处置。但是,由于缺乏直接临场控制以及影

响设备的其他条件超出制造商的条件知识,制造商不对由于运输、安装、使用、储存和处置不当造成的损坏、伤害、

故障和成本负责。

5. 制造商对任何打印物品不承担任何责任,尤其当这些物体构成安全隐患的一部分或受到特定规则的严格管制时,

医疗,军事或空间科学设备。

2.用户指南包括有关“Wiibox Linght”,安全和保护的基本信息准则,以及为第一次使用过程准备机器和基本维护工作,

如果不仔细阅读,可能会导致财产损失,设备故障或 3D 打印质量下降。

3.确保每个 3D 打印机使用者都知道,完全理解并遵循说明本用户指南中提供的操作方式使用。

4.制造商尽一切努力确保产品在运输过程中安全、安装、使用、储存和处置。但是,由于缺乏直接临场控制以及影

响设备的其他条件超出制造商的条件知识,制造商不对由于运输、安装、使用、储存和处置不当造成的损坏、伤害、

故障和成本负责。

5. 制造商对任何打印物品不承担任何责任,尤其当这些物体构成安全隐患的一部分或受到特定规则的严格管制时,

医疗,军事或空间科学设备。

6.由于尺寸和特异性,“Wiibox Linght”不适合未成年人使用,缺少手动,运动和精神运动技能的人。制造商建议,

为希望操作打印机的残疾人和老年人提供帮助和指导。

1. Before the first operation of Wiibox Linght, please read this user guide carefully.

2. User Guidelines include basic information guidelines of safety and protection, and preparation of machines and basic

maintenance for the first use,related with Wiibox Linght. If not carefully read, it may result in property loss, equipment

failure or deterioration of 3D printing quality.

Ensure that every 3D printer user knows, understands and follows the instructions provided in this user guide.

4. The manufacturer shall make every effort to ensure the safety, installation, use, storage and disposal of the product during

transportation. However, because the lack of direct on site control and other conditions affecting the equipment beyond the

manufacturer's knowledge of the conditions, the manufacturer is not responsible for damage, injury, malfunction and cost

caused by improper transportation, installation, use, storage and disposal.

5. Manufacturers shall not be liable for any printed items, especially when such objects form part of a security hazard or

are subject to strict rules governing medical, military or space science equipment.

6. Due to size and specificity, “Wiibox Linght” is not suitable for minors, disability of manual, sports and psychomotor.

Manufacturer recommends providing assistance and guidance to disabled and elderly people who want to operate printers.

General safety information 一般安全信息

本用户指南包含安装期间应遵循的重要安全说明和“Wiibox Linght”的运作。它还提到了需要特别注意的情况,并包

括警告,以防止可能导致损坏或伤害的疏忽和误用。请务必阅读。

This user guide contains important safety instructions followed during installation and the operation of “Wiibox Linght”. It

also refers to situations requiring special attention and includes warnings to prevent damage or injury caused by negligence

and misuse. Be sure to read.

Use Notice 使用注意事项

1.使用“Wiibox Linght”的打印工艺需要使用液态合成树脂,微毒(不可食用),微气味,可能引起过敏反应。因此,

你必须保护你的皮肤和眼睛,佩戴安全手套和眼镜使用打印机。在打印过程中提供适当的通风房间。

2.避免将树脂洒在打印机及其周围环境上也非常重要的。

3.在操作打印机时,确保打印机是水平的,并必须保持在稳定的桌面上。

4.在打印过程中不要打开防尘遮光盖,不能晃动机器以及放置机器的桌面,否则会由于机器的晃动导致打印失败。

5.定期检测您的设备是否磨损。通过联系我们的售后中心,以获得帮助,同时更换磨损或损坏的部分。

6.使打印机远离热源,易燃材料,辐射设备,火源,湿度,水和其他液体。

7.为防止任何意外使用,请放置到儿童和动物无法触及的位置。

8.禁止掉落或摇晃打印机,它可能会导致故障。

9.该设备不适用于潜在爆炸物的环境。

10.制造商强烈建议设置专用于 3D 打印的特殊房间。房间温度 25-28°,应尽量避光,并保持通风良好。

11.避免液态树脂暴露在日光下的情况,否则将导致树脂凝固,无法使用而浪费。

1. Using the printing process of "Wiibox Linght" requires the use of liquid synthetic resin, which is slightly toxic (not

edible), slightly odorous and may cause allergic reactions. Therefore, you must protect your skin and eyes, wear safety

gloves and glasses for using printers. Provide proper ventilation room during printing.

2. It is also very important to avoid spraying resin on printers and their ambient environment.

3. During the operation a printer, ensure that the printer is horizontal and kept on a stable desktop.

4. Don't open the dustproof shading cover during the printing process. Don't shake the machine and the desk that place the

machine. Otherwise, the printing will fail because of the shaking of the machine.

5. Check regularly whether your equipment is worn or not. Contact our after-sales center to get help and replace worn or

damaged parts.

6. Keep the printer away from heat sources, flammable materials, radiation equipment, fire sources, humidity, water and

other liquids.

7. Prevent any accidental use; please place it where children and animals can't touch it.

8. Do not drop or shake the printer which it may cause trouble.

9. The equipment is not suitable for the environment of potential explosives.

10. Manufacturers strongly recommend special rooms for 3D printing. Room temperature is 25-28℃, should avoid light as

far as possible, and maintain good ventilation.

11. Avoid liquid resin exposure to sunlight, otherwise it will cause to resin solidification, unusable and wasteful.

Workplace health and safety 工作场所健康与安全

1.所有服务和维护活动以及设备操作和维护都需要使用工具包中包含的安全手套和眼镜。建议穿戴防护服装。

2.保持工作场所清洁,树脂容器应密闭并保持在黑暗中。

3.应根据制造商所提供的参数配置设备,配置不当可能导致打印不良或导致设备损坏。

4.食品和饮料应远离 3D 打印机和 3D 打印物体。

5.请勿在机器内部放置任何物体。

6.在操作“Wiibox Linght”时,所有有关健康和安全的措施都是如此。

7.本用户指南中提供的以及单独的规定应予以考虑。

1. All service and maintenance activities as well as equipment operation and maintenance require the use of safety gloves

and glasses contained in the toolkit. It is recommended to wear protective clothing.

2. Keep the workplace clean. Resin containers should be sealed and stored

in darkness.

3. The equipment should be configured according to the parameters provided by the manufacturer. The improper

configuration may cause the poor printing or equipment damage.

4. Foods and beverages should be kept away from 3D printers and 3D printed objects.

5. Do not place any objects inside the machine.

6. The same applies to all health and safety measures when operating Wiibox Linght.

7. Provisions provided in this User Guide and separate provisions shall be taken into account.

WIIBOOX LIGHT-3D Printer User Guide

WIIBOOX LIGHT-3D 打印机用户指南

Page 3 of 16

Electric Safety 电气安全

1.“Wiibox Linght”打印机已经过测试,符合低电压指令。

2.为了确保最高的安全标准,包括防止短路,过载,过压和打印机过热,请勿尝试修改打印机,不要使用除制造商

推荐的以外的电子更换零件。

3.根据说明更换电子装置,使用时要特别小心打印机的其他配件。

4.在将电源线插入插座之前,请确保电源电压与设备所需值相匹配,本设备支持 110V/220 电压,但需要手动调节。

5.打印机必须良好接地,始终确保符合当地和国家法规。

6.仅使用打印机随附的原装电源线,不要损坏,切割或修理电缆,损坏的电缆应立即更换新电缆。电缆应该是根据

其预期用途使用,应保护免受热,油,锋利的边缘和移动设备的组件,电缆损坏会增加触电的风险。

7.请勿将设备暴露在阳光、雨水和潮湿的环境中。

8.在用树脂填充材料盘时,请注意不要将树脂洒在材料盘外面,进入设备内部的液体可能会导致设备存在问题。

9.所有维护和修理工作都必须拔下电源线后进行。

10.禁止对电子元件进行焊接等修改。

1. "Wiibox Linght" printer has been tested and meets the low-voltage instructions.

2. In order to ensure the highest safety standards, including preventing short circuit, overload, overvoltage and overheating

of the printer, do not attempt to modify the printer or replace parts electronics other than those recommended by the

manufacturer.

3. Replace the electronic device according to the instructions. Be careful with other parts of the printer during using it.

4. Before plugging the power cord into the socket, ensure that the power supply voltage matches the required value of the

equipment. The equipment supports 110V/220 voltage, but needs manual adjustment.

5. Printers must be well grounded to ensure consistency with local and national regulations.

6. Use only the original power cord accompanying with the printer. Do not damage, cut or repair the cable. The damaged

cable should be replaced immediately. Cables should be used according to their intended use and should avoid breaking

form heat, oil, sharp edges and components of mobile devices. Cable damage increases the risk of electric shock.

7. Do not expose the equipment in the environment of sunlight, rain and humidity.

8. When using resin-filled materiel plate, please not to sprinkle resin on the outside of the materiel plate. The liquid entering

the inside of the equipment may cause problems in the equipment.

9. All maintenance and repair work must be carried out after the power cord is unplugged.

10. It is forbidden to modify electronic components such as welding.

Safety of Machinery 机械安全

1.“Wiibox Linght”具有可移动组件,例如构建平台和 Z轴。因此,禁止进入打印机或在打印机内放任何东西,它正

在运行,或即将开始运行,这可能会导致严重的伤害或损坏。

2.打印机随附的工具和配件应特别注意使用,使用不当可能会导致伤害。

3.在遵循后处理程序的同时,戴上安全手套和眼镜以避免可能由锋利的模型边缘引起的伤害。

4.完成打印后,必须从打印机的打印平台上取下模型

5.为避免受伤,在从平台上取下打印件时要特别小心,必须佩戴手套和眼镜。

6.安装在材料盘的薄膜非常薄且易破损,因此要特别小心,在清洗,安装和拆卸材料盘时应特别注意。

1. “Wiibox Linght” has movable components, such as construction platform and Z axis. Therefore, it is forbidden to enter

the printer or put anything in the printer. It is running, or about to run, which can cause serious injury or damage.

2. While following the post-processing procedure, wearing safety gloves and glasses can avoid injuries caused by sharp

edges of the model.

3. While following the post-processing procedure, wear safety gloves and glasses to avoid possible damage caused by sharp

model edges.

4. After printing, the model must be removed from the printer's printing platform.

5. In order to avoid injuries, take special care when removing the print from the platform. Gloves and glasses must be worn

6. The film installed on the material plate is very thin and fragile, so special care should be taken during cleaning, installing

and disassembling the material plate.

Burn Risk 烧伤风险

因为所有在高温下工作的部件都是封闭的,所以没有灼伤的危险,但是禁止进入机器内部触摸。

Because all parts working at high temperatures are enclosed, there is no risk of burns, but don‘t touch inside the machine.

Safe Storage 安全储存

“Wiibox Linght”器件必须存储在 0到40°C [32 - 95°F]之间。存储空间应该是没有水分和无其他极端条件。

"Wiibox Linght" devices must be stored between 0 and 40℃[32 - 95 ° F]. Storage space should not contain moisture and

other extreme conditions.

About "Wiibox Linght" 有关“Wiibox Linght”

“Wiibox Linght”是一款光固化 3D 打印机,和专用材料一起,构成整个 3D 打印系统。该设备可以使依赖于固化液体

的UV LCD 技术将数字三维项目变为实体光聚合物体。 UV LCD 技术涉及投影层的图像在液体树脂的透明底面上,

使用背光紫外灯固化该层。每层固化后,灯暂停运行。在暂停期间,平台上升和下降,树脂均匀分布。打印机配有

液晶显示屏,负责连续投影层和掩盖紫外线。由于这一点,树脂在图像之外的依然未固化,可用于打印模型的其余

部分。打印机可以同时打印多个部件并不影响精度和打印速度。一旦打印过程完成后,模型必须分两步进行后处理。

第一步是用清洗液体洗涤未固化树脂残留的打印品,第二步涉及额外的 UV 二次固化,以使打印件获得更好的性质。

“Wiibox Linght”可用于在设计中创建原型和概念模型、医疗牙科以及创意应用等。

“Wiibox Linght” is a photo-curable 3D printer and forms the whole 3D printing system together with special materials. The

device enables UV LCD technology relied on solidified liquids, to transform digital three-dimensional items into solid

photopolymers. UV LCD technology relates to an image of a projection layer on a transparent underside of a liquid resin,

which is cured with a backlight ultraviolet lamp. After each layer is cured, the lamp is suspended. During the suspension

period, the platform rises and falls, and the resin is evenly distributed. The printer is equipped with a LCD screen, which is

responsible for continuous projection layer and covering up ultraviolet radiation. Because of this, the resin is not cured

outside the image and can be used to print the rest of the model. Printers can print multiple components simultaneously and

don’t affect accuracy and printing speed. Once the printing process is ready, the model must be postprocessed by two steps.

Firstly, wash the uncured resin residues with a cleaning liquid. Secondly, involves additional UV secondary curing to obtain

better properties of the printer.

“Wiibox Linght” can be used to create prototypes and conceptual models, medical dentistry and creative applications in

design.

How does it work?如何运作?

1.一切都从准备模型开始。创建 3D 模型并生成.stl 文件,这是大多数类型建模软件支持的格式(三角形网格)。

2.下一步是在切片软件中打开.stl 文件(或其他) -通过将模型添加支撑并切割成单个图层并将其保存为 DJS 文件。

切片软件还允许您选择用于模型的材料类型,调整必要的打印设置,如图层厚度,曝光时间等。

3.要开始打印过程,请打开打印机,准备与您在切片软件中选择的材料,并小心地倒入适量的材料在打印机的材料

盘中(含自动供料功能的打印机可以直接将料盒装入打印机即可)。

4.在使用“Wiibox Linght”时,您可以启动,暂停和停止(制造商不建议使用暂停功能,此功能可能导致打印失败或

影响打印模型精度)。

5.准备好文件后,将文件储存到 U 盘并插入设备前端的插口,复制文件到打印机后开始打印。

1. It all starts with preparing the model. Create 3D models and generate. STL files, which are the formats supported by most

types of modeling software (triangular meshes).

2. The next step is to open the. STL file (or other) in slicing software - by adding and supporting to the model and cutting it

WIIBOOX LIGHT-3D Printer User Guide

WIIBOOX LIGHT-3D 打印机用户指南

Page 4 of 16

into a single layer and saving it as a DJS file. The slicing software also permits you to select the material type for the model

and adjust the necessary printing settings, such as layer thickness, exposure time, etc.

3. Be ready to start the printing process, please open the printer, prepare the material y with your selection in the slicing

software, and carefully pour the appropriate material into the printer's material plate(the printer with automatic feeding

function can directly load the material box into the printer).

4. When using “Wiibox Linght”, you allow to start, pause and stop (the manufacturer does not recommend the pause

function, causing the printing failure or influence the accuracy of the printing model).

5. When the files are prepare well, store them on the U-flash and insert them into the front-end of the device. Copy the files

to the printer and start printing.

产品规格 Product Standard

机型技术

LCD 面成型

成型尺寸

130(L)*70(W)*180(H)MM

适用行业

工程零件,手办模型,珠宝模型、牙科应用等

xy 分辨率

0.0026mm²

打印层厚

0.03-0.1mm

打印速度

10-20mm/h

内存

8G

文件格式

STL

软件系统

Windows7 及以上版本(仅支持 64 位系统)

传输方式

U 盘传输

软件

Wiiboox slicer

耗材属性

丙烯酸酯光敏树脂 (液体光敏树脂)

打印耗材

标准树脂,强韧性树脂,铸造树脂、耐温树脂、弹性树脂

设备电压

220V/110V

设备功率

120W

设备尺寸

W270*D230*H375mm

设备重量

10KG(含包装)

工作环境

20℃-28℃

建议环境

Suggestion environment

操作环境:放置在通风良好的无尘区域;温度:20℃-28℃;湿度:20%-80%(无冷凝)。

存放环境:温度:0℃-40℃;湿度:10%-80%(无冷凝);无腐蚀气体存在且清洁的场合。

Operating environment: Place in a well-ventilated and dust-free area; temperature: 20-28℃; humidity: 20-80% (no

condensation).

Storage environment: temperature: 0 - 40℃; humidity: 10% - 80% (without condensation); no corrosive gas and clean

occasions.

包装清单 Pack list

3D 打印机 材料 电源线 一次性手套 塑料铲刀 六角扳手

3D Printer Material Power cord Disposable gloves Plastic spade Hexagon wrench

过滤网 料盘膜*1 USB 校准平台纸

Filter screen Material plate film*1 Calibration Platform Paper

Type technology

LCD Surface Forming

Forming dimension

130(L)*70(W)*180(H)MM

Applicable industries

Engineering parts, hand-made models, jewelry models, dental

applications, etc.

XY resolution

0.0026mm²

Printing layer thickness

0.03-0.1mm

Printing speed

10-20 mm/h

Internal storage

8G

File format

STL/OBJ

Software system

Windows 7 and above (64-bit system only)

Transmission mode

U-flash transmission

Software

Wiiboox slicer

Consumables attributes

Acrylate photosensitive resin (Liquid photosensitive resin)

Printing consumables

Standard resin, obdurability resin, casting resin, temperature

resistance resin, elastic resin

Equipment voltage

220V/110V

Equipment power

120W

Equipment dimensions

W270*D230*H375mm

Equipment weight

10KG

Work environment

20℃-28℃

WIIBOOX LIGHT-3D Printer User Guide

WIIBOOX LIGHT-3D 打印机用户指南

Page 5 of 16

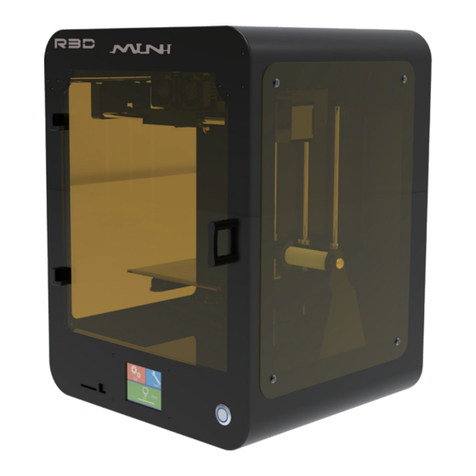

主要部件 Main part

防尘遮光盖

Dust-proof shade cover

电源开关

Power switch

平台固定螺丝

Platform set screws

调节脚垫

Adjustment footpad

打印平台

Printing platform

散热孔

Heat emission hole

材料盘

Material plate

电源插口

Power socket

材料盘固定螺丝

Material plate fixing screw

LCD 成型模块

LCD molding module

3D 打印技术词汇 3D Printing Technology Term

LCD 光固化 3D 打印技术

一种依靠固化光聚合物的技术。LCD 光固化 3D 打印技术涉及在材料盘下投射连续层的图像,使用液态树脂并使用

紫外光固化它们。

LCD Photocurable 3D Printing Technology

A technology is that relies on curing light polymers. LCD photo-curing 3D printing involves projecting images of

continuous layers under a material plate and cures them by liquid resins and UV light.

防尘遮光盖

防尘遮光盖在打印机的顶部,负责保护液体树脂环境紫外线以及粉尘进入材料。它还有助于在打印中减少令人不快

的树脂气味。

Dust-proof shade cover

Dust-proof shade covers the top of the printer and is responsible for protecting the liquid resin environment from ultraviolet

rays and dust entering the material. It also contributes to reduce unpleasant resin odor in printing.

Z轴

负责打印平台的上升和下降,由平面的固化逐渐形成立体。

Z axis

Be responsible for the rise and fall of the printing platform, and gradually form three-dimensional from the from the

solidification of the plane.

打印平台

打印机的一个组成部分,模型在树脂聚合过程中粘附在其上。此外,它在打印过程中上升和下降,使逐层固化, 它

可以很容易地取下和安装。

Print Platform

A component of a printer is on which a model is attached during resin polymerization. In addition, it rises and falls during

the printing process and it solidify layer by layer. It can be easily removed and installed.

材料盘

在整个打印过程中盛放液态树脂的容器。它由金属框架和高分子薄膜组成。材料盘是用两个螺丝直接固定在打印机

上。材料盘属于消耗品,料盘膜在刮花、破损后需要及时更换,破损后如果继续使用将会连带损坏打印机 LCD 成

型模块。

Material plate

A container keeps liquid resin throughout the printing process. It consists of a metal frame and a polymer film. The material

plate is fixed directly on the printer by two screws. Material plate belongs to consumables. Material plate film needs to be

replaced timely after scratching and breakage. If it continues to use after breakage, it will damage the printer LCD forming

module.

LCD 成型模块

LCD 成型模块是 LCD 光固化 3D 打印技术中至关重要的部件。它是负责用于在整个材料盘底面上投影图像并掩盖

其他紫外线,使树脂在图像之外区域不会固化。它属于打印机的一个消耗品,制造商质保期为 2个月,但容易拆取

和更换。

LCD Molding Module

LCD molding module is an important component in LCD photo curing 3D printing technology. It is responsible for

projecting the image on the bottom of the entire material plate and covering up other ultraviolet rays so that the resin will

not be solidified outside the image area. It belongs to a consumable of printers. The manufacturer's warranty period is 2

months, but it is easy to dismantle and replace.

触摸屏

触摸屏位于打印机前部,可实现快速直观的进行设备操作。屏幕还显示当前的打印过程和有关打印机的其他信息。

Touch screen

Touch screen is located in the front of the printer and can realize fast and visual device operation. The screen also displays

the current printing process and other information about the printer.

WIIBOOX LIGHT-3D Printer User Guide

WIIBOOX LIGHT-3D 打印机用户指南

Page 6 of 16

工具包套件

该套装包含工具和防护用品,包括例如材料盘薄膜,漏斗和铲刀等。操作打印机需要使用工具包中的工具,以及执

行维护工作。

Toolkit suite

The suit contains tools and protective supplies, such as material plate film, funnel and spade. The tools in the toolkit is used

to operate the printer and perform maintenance work.

支撑

使用支撑软件添加特殊的 3D 打印结构,以支柱的形式确保整个模型粘附在平台上,在打印过程中不会落入材料盘

中。支撑使用与模型相同的材料打印。打印完成后,必须手动或使用钳子从模型中移除支撑。

Support

Use the support software to add special 3D printing structure to ensure that the whole model adheres to the platform in the

form of support, and does not fall into the material plate during the printing process. The support uses the same material as

the model for printing. After printing, support must be removed from the model manually or with pliers.

底板

这些层总是在支撑生成时自动生成,并且具有比打印模型更大的区域,保证模型粘附在打印平台上。一旦打印完成

后,需要将底板与模型一起从平台上移除。

底板增加了打印模型和支撑结构对平台的粘附力。

Baseplate

These layers are always automatically generated when support is generated, and have larger areas than print models to

ensure that models are able to adhere to print platforms. Once the printing is finishing, both the baseplate and the model

require to be removed from the platform. The baseplate increases the adhesion of the printing model and the supporting

structure to the platform.

切片

将要打印的模型分层,使打印过程中逐层投射并固化成型

.DJS 文件

由本 3D 打印机配备的切片软件生成的一种文件格式,其中包含准备的 3D 打印模型、打印设置,例如图层曝光时

间,曝光关闭时间, 在生成.DJS 之前,可以在切片软件中管理所有打印设置。

.DJS file

It is a file format generated by the slicing software equipped with this 3D printer including the prepared 3D printing model,

printing settings, such as layer exposure time, exposure shutdown time, and all printing set can be managed in the slicing

software before. DJS is generated.

切片软件

专为 3D 打印设备创建的应用程序,切片软件将准备的 3D 模型生成 DJS 格式的文件进行打印。切片软件允许用户

改变并调整打印设置,例如模型的大小,图层厚度或曝光时间等、并且将为模型添加支撑结构。最后一步是通过

Wi-Fi 或使用 USB 储存器将文件传输到打印机。

Slice software

Slicing software is an application created by specifically for 3D printing devices that generates a .DJS file of the prepared

3D model for printing. Slicing software allows users to change and adjust print set, such as model size, layer thickness or

exposure time, and will add support structures for the model. The last step is to transfer files to the printer by Wi-Fi or a

USB memory.

料盘清扫

使用紫外线创造的一种清洁的方式,可以快速地在材料盘内固化一整片的树脂,然后用户从边角将整片固化层取出,

达到清理料盘的目的。

Material plate cleaning

Ultraviolet ray creates a clean way and can quickly solidify a whole piece of resin in the material tray, and then the user

takes out the whole solidified layer from the corner to achieve the purpose of cleaning the material plate.

清洗盒

清洗打印模型的容器,盛放酒精等清洗剂,用于清洗模型表面的液态树脂。

Cleaning box

Clean the container of the printing model; fill alcohol and other detergents to clean the liquid resin on the surface of the

model.

首次使用准备工作 Preparation Work for First Use

1. 从外箱底部划开胶带,然后将整个打印机外箱从上面抽出。

1. Cut the tape from the bottom of the outer box, and then pull out the whole printer outer box from the top.

2. 取出打印机包装缓冲泡沫,并拿出工具包和其他资料文件。

2. Take out the printer packaging buffer foam and take out the toolkit, other information files.

3. 从工具包中取出调节脚垫并安装到打印机底座,放置到平整的桌面,调节脚垫使机器能保持平稳不晃动。

3. Take out the adjustment footpad from the toolkit and install it on the foundation of the printer. Place it on a flat table.

Keep the machine stable and no-shake by adjustment footpad.

WIIBOOX LIGHT-3D Printer User Guide

WIIBOOX LIGHT-3D 打印机用户指南

Page 7 of 16

4. 插入电源线并开启打印机。

4 .Insert the power cord and turn on the printer.

5.进入主菜单界面,将Z轴抬升 50mm(如下图顺序)

5. Enter the main menu interface,lift the Z axis by 50mm ( As shown in below).

6.检测设备曝光情况

6.Test equipment exposure

曝光 曝光正常

Exposure Normal exposure

7. 检测平台的对准

7.Check the platform alignment

a.取下材料盘,逆时针拧松料盘固定螺丝,将料盘和螺丝同时取出。

a. Take out the material plate and unscrew the fixed screw counterclockwise in the material plate. Take out the material

plate and the screw at the same time.

b.在LCD 成型模块上放置打印机附带的测试纸(如下图放置)

b. Place the test paper attached to the printer on the LCD molding module (as shown below)

c.将平台回“0”,压住纸条并进行拉动测试(如不正常再请观看随机附带的调节视频)

c. Return the platform to "0", hold down the strip and carry out the pull test (if abnormal, please watch the random

accompanying adjustment video)

回“0” 无法拉出纸条(或感觉纸条摩擦)则正常

Back “0” Failure to pull the strip (or to feel the strip rub) is normal

WIIBOOX LIGHT-3D Printer User Guide

WIIBOOX LIGHT-3D 打印机用户指南

Page 8 of 16

8. 完成平台校准,此过程可确保在打印过程中,平台与 LCD 屏幕保持正确的距离,避免打印脱底导致的失败。

8.Complete platform calibration, which ensure the correct distance between the platform and the LCD screen during the

printing process, and avoid the failure caused by printing bottom off .

9.您已完成打印机基础设置,您的设备已准备好进行打印。

9.You have completed the printer basic set and your device is ready for printing.

切片支撑软件“wiibooxslicer”使用

Use of Slice Support Software "wiibooxslicer"

一、安装软件(支持:windows7、windows10 64 位系统)

Ⅰ. Installation of software (support: Windows 7, Windows 1064-bit system)

1、打开“wiibooxslicer”文件夹,双击“cleancache”程序安装

1.Open the "wiibooxslicer" folder and double-click the "clean cache" program to install

2.双击 打开软件

2.Double-click to open software

3.选择语言,仅支持中/英文

3. Select language, and support Chinese/English only

4 .软件常用基本功能介绍

4. Introduce to software commonly used basic functions

二、导入零件并编辑模型

Ⅱ. Import parts and edit model

1 .打开文件导入

1. Open file import

2 .通过拉动或者输入数据旋转模型倾斜 30-45°,便于添加支撑和打印

WIIBOOX LIGHT-3D Printer User Guide

WIIBOOX LIGHT-3D 打印机用户指南

Page 9 of 16

*此步骤需要一定的 3D 打印技巧,打印机随机资料包含部分视频教程,请仔细观看学习

2 .By pulling or inputting data to rotate the model tilt 30-45, it is easy to add support and print.

* This step requires some 3D printing skills. Printer random data includes some video courses. Please watch and

learn carefully.

3.选择打印层厚

3.Select Print Layer Thickness

4.确认打印材料,根据材料型号选择对应参数

4. Confirm printing material and select corresponding parameters according to material type

三、支撑添加和切片

Ⅲ. Support addition and slicing

1 .自动生成支撑

1. Automatically generate support

2. 编辑、修理支撑,并勾选“锁定浮空位置下的支撑”(蓝色支撑点为浮空位置)

2. Edit and repair the support, and select "Lock the support under the floating position" (the blue support point is the

floating position).

3. 在缺少部分补充支撑,鼠标左键点击添加支撑点,如果无添加支撑相应经验,请观看随机附带的相关视频资

WIIBOOX LIGHT-3D Printer User Guide

WIIBOOX LIGHT-3D 打印机用户指南

Page 10 of 16

料

3. When being short of supplementary support, click on the left mouse button to add support point. If there is no

experience to add support points, please watch the relevant video materials attached randomly.

4. 删除多余支撑,鼠标右键删除或者“shift+鼠标左键”框选,按“Delete”键删除

4. When deleting surplus support, click right mouse button to delete or select "shift + left mouse button", and press the

"Delete" key to delete

5、支撑手动编辑完成后,应用支撑修改

5.After finish manually editing the support, apply the support modification.

6.完成支撑添加

6. Complete support addition

7.切片

7. Slice

8.预览切片,此步骤可以帮助您检测模型中是否存在破面,如有发现模型损坏必须先进行修复

8.Preview slices, and this step can help you detect whether there is a fraction in the model, If any model damage is

found, it must be repaired first.

9 . 导出“dis”文件

WIIBOOX LIGHT-3D Printer User Guide

WIIBOOX LIGHT-3D 打印机用户指南

Page 11 of 16

9. Export "dis" file

10.通过 U盘传输至机器

10. Transfer to machine by U flash

启动打印 Start Printing

警告!

在所有操作程序中必须佩戴手套和眼镜。

准备好纸巾并将其放在工作场所以擦拭液体。

Warning!

Gloves and glasses must be worn in all operating procedures.

Prepare paper towels and place them in the workplace to wipe the liquid.

注意!

打印和后处理废物,包括空瓶,打印失败,支撑,底板,以及带树脂残留物的纸巾应放在紫外光下进行固化处理。

未固化的树脂必须按照处理关于危险废物的国家和地方法规。关于所用液体洗涤剂的使用和废物处理的详细信息在

制造商提供的 MSDS 文件中找到。

Notice!

Printing and post-treatment waste should be cured under ultraviolet light, including empty bottles, printing failure, support,

backing, and paper towels with resin residues. Unsolidified resins must be treated in accordance with national and local

regulations for hazardous wastes. Detailed information on the use of liquid detergents and waste disposal used is found in

the MSDS file provided by the manufacturer.

1.检查设备: 如果在打印机安装过程中未检测平台校准,请执行这个程序。

检查设备电源接通情况,确保稳定的电路环境

打印机材料盘是否干净、安装是否稳固

打印平台是否干净、安装是否稳固

检查完成后关闭防尘遮光盖

1. Check equipment: If the platform calibration is not detected during the printer installation, please execute this procedure.

Check power connection of equipment to ensure stable circuit environment. Whether the printer material plate is clean and

the installation is stable. Whether the printing platform is clean and installation is stable. Close the dustproof shading cover

after inspection.

2. 添加材料: 将储料盒轻微摇晃半分钟,避免因静止而导致的材料沉淀。

料摇晃后倒入打印机材料盘中,材料量不可超过图示台阶位置。

2.Additional material: Gently shake the storage box for half a minute to avoid sediment of the material due to static.

After the material is shaken, pour it into the printer material tray. The amount of material should not

exceed the position of the step shown.

3.将通过“wiibooxslicer”处理好的 DJS 文件放置到 U盘,并按以下顺序操作打印机(WIFI 打印请参见独立的 wifi 操

作说明书)。

3. Use preparation work Store the .DJS file processed by "wiibooxslicer" onto a USB flash drive and operate the printer in

the following order (please refer to separate WIFI operating instructions for WIFI printing).

a.进入文件选择栏 b.打开“sda1”(sda1 为当前插入的 U盘)

a. Enter the file selection bar b. Open "sda1" (sda1 is the U disk currently inserted)

WIIBOOX LIGHT-3D Printer User Guide

WIIBOOX LIGHT-3D 打印机用户指南

Page 12 of 16

c.选择打印文件 d.确认打印

c. Select the print file d. Confirm print

e.等待开始曝光后即可拔出 U盘

e. Wait for the exposure to start, then you can pull out the USB flash drive.

4.通过打印机屏幕显示界面信息可以预算打印完成时间。

4.Printing completion time can be estimate by displaying interface information on the printer screen.

后处理 Post—process

1. 完成打印过程后,请等待模型表面树脂大部分从模型中排出。

1. After finishing the printing process, please wait for most of the resin on the surface of the model to be discharged from

the model.

*根据模型的大小和几何形状,您可以对平进行转动让树脂更多的流入材料盘内,以节省液态树脂。

* According to the size and geometry of the model, you can rotate horizontally so that more resin flows into the material

plate to save liquid resin.

2. 带上防护手套,拧松平台固定螺钉(约拧动两圈)。取下平台,小心不要将液体树脂洒在打印机及其周围。

2. Wear protective gloves and unscrew the platform fixing screw (about two turns).Take out Platform and be careful not to

spray liquid resin around the printer.

3. 带上防护手套,使用美工刀或其他比较薄的工具,将模型沿边缘取下,必须注意安全。

3. Wear protective gloves and use a utility knife or other thinner tool to remove the model along the edge. Care must be

taken.

WIIBOOX LIGHT-3D Printer User Guide

WIIBOOX LIGHT-3D 打印机用户指南

Page 13 of 16

4. 将取下的模型放入酒精清洗盒(自备),浸泡约 3-5 分钟(不可超过 10 分钟),然后轻轻晃动模型清洗掉模型表

面粘附的树脂。

4. Put the removed model into the alcohol cleaning box, soak for about 3-5 minutes (not more than 10 minutes), then

gently shake the model to clean the resin adhering to the surface of the model.

5.去除支撑,从模型边缘破坏支撑结构后撕下全部支撑,必须佩戴防护手套,注意防止模型尖锐部分划伤。

5. Remove the support and all supports were torn off after the support structure was destroyed from the edge of the model.

Protective gloves must be worn. Be careful to prevent sharp scratches on the model.

6.将模型放入 UV 二次固化机或任何紫外线源下(例如直射阳光)。

*根据您用于打印的树脂类型选择二次固化时间,此步骤是可选的。

6.Place the model in a UV secondary curing machine or any ultraviolet source (such as direct sunlight).

* Select the secondary curing time according to the type of resin you use for printing. This step is optional.

7. 对模型表面进行简单打磨处理,您可以使用锉刀、粗细砂纸等工具配合打磨,以达到较好的表面效果,必须佩戴

手套防止对树脂有过敏反应

7. Carry out the simple polishing on the surface of the model. 8. You can use tools such as file and sandpaper to polish in

order to achieve better surface effect. Gloves must be worn to prevent allergic reaction to resin.

8.将平台完全清理干净,无任何固化物或其他杂质后安装到打印机,并关闭防尘遮光盖

*材料在 7日内不使用的情况下不用回收,超过 7日应该将材料回收到相应的材料瓶内储存,以免长时间暴露在空

气中变质.

*打印机以及材料都不能放置在阳光照射的位置或窗口,阳光中包含的大量紫外线会使材料固化报废。

*不能放置在射灯或其他强光 led 灯下。

8. Clean up the platform completely, install it to the printer without any solidification or other impurities, and close the

dustproof shading shield.

* Material shall not be recycled if it is not used within 7 days. Material should be recycled to store in corresponding

WIIBOOX LIGHT-3D Printer User Guide

WIIBOOX LIGHT-3D 打印机用户指南

Page 14 of 16

material bottles for more than 7 days in order to avoid the deterioration in the air for a long time.

* Printers and materials cannot be placed in the sunshine location or window. The large amount of ultraviolet light

contained in sunlight can make the material solidify and scrap.

* Do not place under spotlights or other strong LED lights.

9.打印机长时间不使用回收材料

将过滤漏斗插入瓶子中,将材料盘的树脂通过漏斗倒入瓶中。如果有必要,可以使用纸牌等纸质卡片对料盘进行清

理。

9. Printers do not use recycled materials for a long time

The filter funnel is inserted into the bottle, and Pour the resin on the material plate into the bottle through a funnel. If

necessary, paper cards such as cards can be used to clean the plate.

10.用纸巾和 95°酒精清洗剂擦拭材料盘。

10. Wipe material dishes with paper towels and 95°alcohol detergent.

11.用干净的软布清洁 LCD 屏幕和 FEP 薄膜的外部

11. Clean the LCD screen and exterior of FEP film with clean soft cloth.

12.将清理干净的材料盘安装回打印机中

12. Install the clean material plate back into the printer.

关于打印失败的处理 Treatment of Print Failures

*.此项说明仅在打印的模型脱离平台、支撑与模型脱离、模型断裂的情况适用。如有其他原因导致的打印失败,请

在故障排除项内寻找解决方案或联系售后支持解决。

* This explanation is applicable only when the printed model is separated from the platform, the support is separated from

the model and the model is breakage. If printing fails due to other reasons, please find solutions in troubleshooting items or

contact after-sales support to solve them.

*必须佩戴防护手套、眼镜

* Protective gloves and glasses must be worn

1. 将打印品台取出清理干净

1. Take out the print product platform and clean up.

2. 使用料盘清扫功能对材料盘树脂固化一层

2. Solidify the resin layer of the material plate by cleaning function of the material plate.

3. 将固化物沿料盘边缘取出并及时擦拭洒在设备上的液体材料。

3. Take out the solidified material along the edge of the plate and wipe the liquid material on the equipment in time.

4.清理完成,安装平台至打印机即可

4. Clean up and install the platform to the printer.

更换材料 Change the material

1. 将材料盒取出,打开自动进料开关,使自动进料系统运行 1分钟,将上一次剩余在管内的材料流进材料盘,以

减小对新更换材料的污染(同型号材料的更换忽略此步骤)。

1. Take out the material box, and open the automatic feeding switch so that the feeding system run asthmatically for 1

minute, and flow the remaining material in the tube into the material tray in order to reduce the pollution of the new

replacement material (the replacement of the same type material ignores this step).

2.取下材料盘

*如果经常更换材料,制造商建议购买多个材料盘替换,以减少繁杂的操作、材料的损耗以及对材料盘的损害。

2. Take out the material tray

* If material is replaced frequently, the manufacturer suggests purchasing multiple material plate to replace them in order to

reduce complicated operation, material loss and damage to the material disks.

3.将树脂过滤漏斗插入瓶中,倒入树脂。如有必要,请用纸牌等纸质卡片对料盘进行清理。完成后,用液体洗涤剂

或异丙醇清洁材料盘。

3.Insert the resin filter funnel into the bottle and pour in the resin. If necessary, clean the plate with cards and other paper

cards. After completion, clean the material tray with liquid detergent or isopropanol.

WIIBOOX LIGHT-3D Printer User Guide

WIIBOOX LIGHT-3D 打印机用户指南

Page 15 of 16

4.将清洁干净并风干的材料盘装入打印机固定。

4. Fix the clean and air-dried material tray into the printer.

5.装入新的材料盒并开启自动进料开关,加材料 5分钟

5. Install the new material box and turn on the automatic feeding switch. Add the material for 5 minutes.

无自动进料功能的设备直接往材料盘注入新的材料,树脂量必须符合材料盘标识的范围。

The equipment without automatic feeding function injects new materials directly into the material plate, and the resin

content must conform to the scope of the material plate marking.

6.完成材料更换,关闭防尘遮光盖。

6. Complete material replacement and close the dustproof and shading cover.

可用材料 Available Materials

建议使用制造商指定材料,制造商只提供指定材料对应的参数

It is recommended to use the materials specified by the manufacturer. The manufacturer only provides the parameters

corresponding to the specified materials.

基本维护和服务工作 Basic Maintenance and Service Work

维护工作应定期进行,以保持打印机的良好状态,获得高质量的打印产品。

Maintenance should be carried out regularly in order to keep the printer in good condition and obtain high quality printing

products.

在开始任何维修之前,正常关闭打印机,让它冷却下来。

Before starting any repairs, shut down the printer and let it cool down.

设备内部有高压电,在任何维护、维修之前必须拔掉电源线,避免触电

There is high voltage power inside the equipment. Before any maintenance and repair, the power cord must be unplugged to

avoid electric shock.

打印机配有执行维护服务所需的相关工具

Printers are equipped with the tools needed to perform maintenance services.

丝杆和导轨:定期检测是否有充足的润滑油

Lead screw and guide rail: periodically check whether there is enough lubricant

清洁机器:使用柔软的布料擦拭,不能使用 IPA 或化学清洁剂

Clean machine: Use soft cloth to wipe. Do not allow to use IPA or chemical cleaner.

清洁液晶显示屏屏幕:使用柔软的布料擦拭,可适当的喷洒 IPA 后擦拭干燥

Clean LCD screen: use soft cloth to wipe. Spray IPA properly and wipe dry.

清洁材料盘:在材料盘中添加一部分 IPA,使用软纸巾或柔软的布料擦拭

Clean material plate: Add a part of IPA to the material plate and wipe it with soft paper towel or soft cloth.

更换材料盘薄膜:参考打印机所配资料 USB 储存器内的更换材料盘薄膜视频

Replace material plate film: Refer to the replacement material disk video in the USB storage packet provided by the

printer.

支持和故障排除 Support and Troubleshooting

为了确保每个 3D 打印机用户的安全,制造商提供各种服务支持,同时解决技术问题。如果操作此打印机有困难,

首先应该寻求指导。在本用户指南中,请查看提供的手册。下面列出了最常见的问题以及可能的解决方案。

In order to ensure the safety of each 3D printer user, the manufacturer provides a variety of service support, and solves

technical problems. If it is difficulty to operate this printer, you should firstly seek guidance. In this user guide, see the

manual provided. The most common problems and possible solutions are listed below.

一、在打印过程中,打印件不会粘附到平台上

Ⅰ. During the printing process, the print will not stick to the platform

1.确保模型设计正确,网格没有包含任何错误。

2.确保在切片中准备文件时选择了对应材料的参数设置,即打印设置与使用的树脂类型相匹配。

3.确保平台和材料盘都是干净的,没有任何的固化树脂残留物或其他杂质。

4.确保液体树脂中没有固化残留物。

5.再次进行平台校准检测。

6.检查材料盘膜是否弯曲,变形或穿孔。如果,请更换材料盘薄膜

1. Make sure the model is designed correctly and the grid contains no errors.

2.Make sure that the parameter set of the corresponding materials are selected when preparing the files in the slices, that is,

the print set match the resin type used.

3. Make sure the platform and material plate are clean and free of any residual resin or other impurities.

4. Make sure there is no solidified residue in the liquid resin.

5. Platform calibration test is carried out again.

6. Check whether the material plate is bent, deformed or perforated. If so, please replace the material disc film.

二、打印品分层或不粘附在支撑结构上

Ⅱ. The print product is layered or does not adhere to the support structure

1.确保模型设计正确,网格没有包含任何错误。

2.如果支撑结构是在不同的程序中生成的,确保模型的网格是固定的。

3.确保准备文件时选择了合适的打印配置文件,即打印设置与使用的树脂类型相匹配。

4.检查材料盘薄膜是否松动,弯曲,变形或穿孔。如有,请更换材料盘薄膜

5.检查材料量是否充足,根据材料盘标识范围计算

1. Make sure the model is designed correctly and the grid contains no errors.

2. If the support structure is generated in different programs, ensure that the mesh of the model is fixed.

3. Make sure that the appropriate print configuration file is selected when preparing the file, that is, the print settings match

the type of resin used.

4. Check whether the material plate film is loose, bent, deformed or perforated. If yes, please replace the material disc film.

5. Check whether the material quantity is sufficient, and calculate according to the marking range of the material disc

三、打印完成后发现打印平台和材料盘中均无固化物

Ⅲ. After printing, it is found that there is no solidified material on the printing platform and material plate

1、确保模型设计正确,网格没有包含任何错误。

2、将打印平台和材料盘依次取下,打开曝光检测画面(请使用挡光板遮挡出料口),观察曝光是否正常:

如无任何光线,则需要更换打印机内部光源

如有光线,但 lcd 模块无法正常投射画面,则需要更换 lcd 成型模块

1. Make sure that the model is designed correctly and that the grid does not contain any errors.

2. Take out the printing platform and material plate in turn, open the exposure detection screen (please use the light barrier

to shield the outlet), and observe whether the exposure is normal:

If there is no light, replace the printer internal light source.

WIIBOOX LIGHT-3D Printer User Guide

WIIBOOX LIGHT-3D 打印机用户指南

Page 16 of 16

If there is light, but the LCD module cannot properly project the picture, it is necessary to replace the LCD module.

四、打印模型与设计模型不一样

Ⅳ. Print model is different from design model

1.确保模型设计正确,网格没有包含任何错误。

2.更换较好质量的 U盘,或复制文件至打印机在打印

1. Make sure the model is designed correctly and the grid contains no errors.

2. Replace better quality U flash or copy files to printer, then print.

五、打印机操作界面无反应

Ⅴ. The printer interface is no response

将打印机断电强重启

Turn off the printer and forced to restart it

六、其他打印故障

Ⅵ. Other Printing Failures

打印模型出现不规则断裂:检查材料盘薄膜是否发白或者穿孔损坏

打印模型表面有穿孔:使用检测曝光功能查看 lcd 成型模块是否存在黑点

The printing model has irregular fracture: check whether the film of material plate is white or damaged by perforation

The print model has a perforated surface: use detection exposure function to check whether there are black spots in the LCD

forming module

回收 Recovery

处理纸张和塑料包装

Disposal paper and plastic packaging

为了保护环境,制造商建议放置用过的纸张和塑料包装在专门指定的容器中,根据您当地的回收准则。处理树脂,

打印和后处理废物,包括空瓶,打印失败,支撑,筏以及带树脂残留物的纸巾应放在紫外线站或任何地方处理前的

紫外线光源。未固化的树脂必须按照处理关于危险废物的国家和地方法规。关于所用液体洗涤剂的使用和废物处理

的详细信息。

In order to protect the environment, manufacturers recommend placing used paper and plastic in specially designated

containers, in accordance with your local recycling guidelines. Printing and post-treatment waste should be cured under

ultraviolet light, including empty bottles, printing failure, support, backing, and paper towels with resin

residues.Unsolidified resins must be treated in accordance with national and local regulations for hazardous wastes.

Detailed information on the use of liquid detergents and waste disposal is found in the MSDS file provided by the

manufacturer.

清洁 3D 打印应该在液体生产商提供的 MSDS 中找到。设备中包含的物质可能是对自然环境有害。废电器和电子设

备不能在垃圾填埋场处理,必须回收。有关何处处置的信息废弃设备,请联系经销商,制造商或设备的进口商。废

弃电气和电子设备与其他废物一起处理。如有问题,请通过售后支持与制造商联系

Clean 3D printing should be found in MSDS provided by liquid manufacturers. The substances contained in the equipment

may be harmful to the natural environment. Waste electrical and electronic equipment cannot be disposed of in landfills and

must be recycled. For information on the place to dispose of obsolete equipment, please contact the dealer, manufacturer

or importer of the equipment. Waste electrical and electronic equipment is disposed of with other wastes. If you have any

questions, please contact the manufacturer through after-sales support.

FCC Warning

This device complies with part 15 of the FCC rules. Operation is subject to the following two conditions: (1) this device may not

cause harmful interference, and (2) this device must accept any inte rference received, including interference that may cause

undesired operation.

Changes or modifications not expressly approved by the party responsible for compliance could void the user's authority to

operate the equipment.

NOTE: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to part 15 of the

FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation.

This equipment generates uses and can radiate radio frequency energy and, if not installed and used in accordance with the

instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not

occur in a particular installation. If this equipment does cause harmful interferenceto radio or television reception, which can be

determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one or more of the

following measures:

-Reorient or relocate the receiving antenna.

•Increase the separation between the equipment and receiver.

•Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

•Consult the dealer or an experienced radio/TV technician for help.

Radiation Exposure Statement

This equipment complies with FCC radiation exposure limits set forth for an uncontrolled environment. This equipment should be

installed and operated with minimum distance 20cm between the radiator and your body.

Table of contents

Other Wiiboox 3D Printer manuals