Wiiboox LuckyBot User manual

01

Product introduction

LuckyBot is a

food

30

printer extruder developed

for

FOM

30

printers,

make your

30

print process more fun, loving and tasty! LuckyBot, Be more

for

you!

-----

Lead Screw

Button-----+-----1t11

@©

@)

~

Plunger

Side door

Enclosure

~

--

----

--------

---

--

-

-------

---

----

------

--

----~

Packing list

No.

Product Name Type Quantity

1 LuckyBot Standard 1set

2 Tube Empty 1pc

3 Wire

Line-10

1pc

4 Soket head cap screw

M3*8

4pcs

5 Inner hexagon wrench L type 1pc

6 Metal adapter plate

2in1

universal plate 1pc

7 Metal needle

18#

2pcs

8 Plastic needle 18G 2pcs

9 Limit wire

200L

1pc

10

E-axis line -1pc

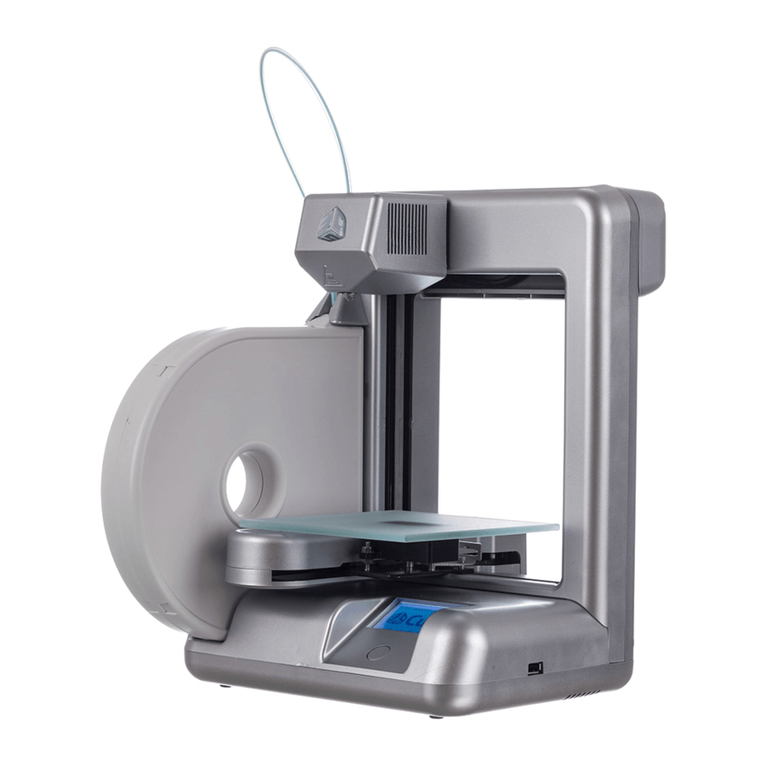

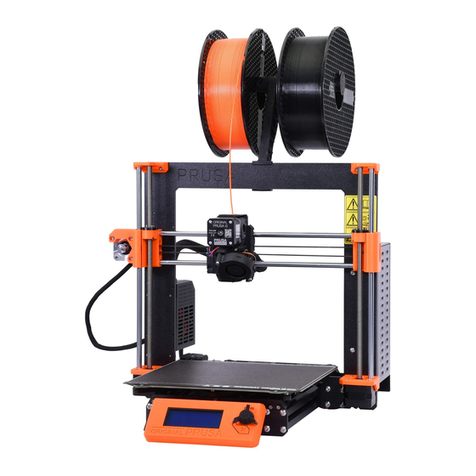

2,

Remove the FDM 3D printer's original

nozzle assembly

Before installing the Luckybot extruder, Please remove the original heating

nozzle assembly from the

FDM

3D printer. Here are specific steps(take

Creality Ender-3

as

an

example) :

1) Remove the cover

of

the nozzle assembly.

Remove

Tip:

The

inner

hexagon

wrench

provided

in

the accessory

box

will

help

you

a lot.

04

05

2) Remove the heating nozzle

of

the nozzle assembly.

Important Notes:

G)

The circuit part

of

the original nozzle assembly can not be removed,

otherwise,

it

will cause the original

FDM

30

printer can not be used again .

(2)

After the original nozzle component is removed,

it

can not

be

placed

randomly, because the nozzle assembly

is

going

to

keep getting heated

during the printing process.

Remove

Tip:

The

inner

hexagon

wrench provided

in

the accessory box will

help

you

a lot.

3,

Install the metal adapter plate

Tip:

The

inner

hexagon

wrench provided

in

the accessory box will

help

you

a lot.

2) Connect the plug wire at the other end

of

line-1

OP,

then switch on the

power supply.

Adaptor

*The

power adapter shown in the figure

is

optional, specific instructions are on

the

adapter box.

07

6,

Install

a needle

IJ

Tip: chocolate printing uses metal needles.

If

you need

to

print other materials, please

use plastic needles instead.

09

Notes:

CD

Recommended

to

tilt the plunger, to insert easier, then turn it upside down.

(2)

Manually shake the tube to squeeze the air out

of

the tube, so that there is

no

bubble

in

the middle

of

the chocolate.

5,

Refrigerate the chocolate tube after filling

Printing process

1, Set 3D printer's parameters

Some parameters

in

the initial configuration file

of

the original

FOM

30

printer do not conform

to

print food, so we need

to

set a new configuration

file before printing.

Advanced

Settings

Xsteps/mm:

Ysteps/mm:

Zsteps/mm:

Esteps/mm

:

80.0

80.0

400.0

750.0

Notes: Changes

of

Creality Ender

3/3s

configuration parameters: initial screen -

ControH

Motion-

Step/mm -Esteps/mm (Change the original value

to

750).

2,

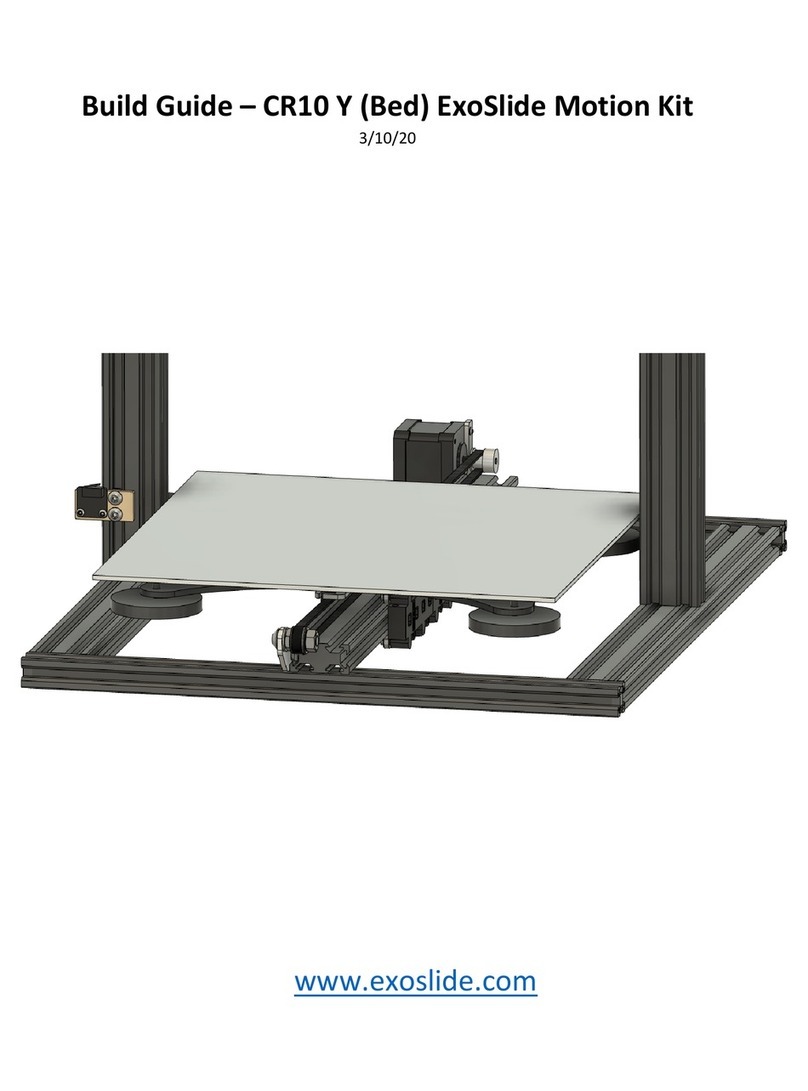

Print platform leveling

1) Some types

of

FOM

30

printers have automatic leveling function. If there

is no automatic leveling function, the traditional 9 point leveling method can

be

used

for

leveling.

2)

When

the gap is too large or small,

it

is necessary

to

adjust the height

of

the Z-axis limit switch

to

ensure that the gap between the platform and the

needle is within 0.5mm. If the length

of

the Z-axis Limit switch line is not

enough when moving, you can

use

the Limit extension line Luckybot provided.

·----------------------·

<0.5mm

3,

Fixed baking paper

Put the baking paper

flat

on

the printing platform.

4,

Place the tube

and

operate to preheat

o~

'l

OJ

Tip: The preheating time is 25-35min, and the preheating temperature can be

adjust-

ed

according

to

the nature

of

chocolate. Please refer to ((Chocolate Temperature

Adjustment Parameter Table))

in

this manual (see

P1

3).

10

11

5,

Prepare 3D file to slice

This manual provides ((LuckyBot Chocolate Printing Slicing Parameter

Table

))

(see P13

in

this manual), refer

to

the table

for

slicing different

models.

~

Cura

-15.04 D X

fi

le

Tools

Machine

Expert

He

lp

Ba~c

Advi

n

ced

Plugi'"Js

Start/End

-

Geode

Quality

Layer

he~ht(mm)

l:;aa

o.=4

=='iii

She

l

th

ickness

(rm,) i.;,2_

_.._

Ellab~

re

tractio

n 0 D

Fdl

B

otto1TV

T

00

thick

n

ess

(nm)!

0.4

I

FiDeasitv(%)

!

so

ID

Speed

and

Temperature

P

rint

speed

(m1TVs)

!1=

25

====;

P

rint:i'"JQ

temperature

{C

)

1~

20

_0

---~

Support

Support

type

N

one

P

latform

adhes

i

on

type

[N

one

Fiiament

D

iameter

(mm)

21

flow(%) 1,

00.0

Tip:

We

recommend you

to

visit www.luckybot.us

to

search the model files you

interest. The slicing software used is also provided by original

FDM

3D

printer

itself. You only need

to

open the original

FDM

3D

printer software,

no

need

to

learn

additional software knowledge.

6,

Pre-extrusion

In

order

to

better perform the printing process, the air

in

the tube should

be

exhausted by pre-extrusion before printing.

7,

Start printing work

The process

of

chocolate printing is the same

to

PLA printing. The sliced

G-code

file is copied into TF card and then inserted into

FDM

30

printer.

Select the file

to

be printed

on

the printer's interface.

Important Notes:

G)

Due

to

the characteristics

of

pure

fat

chocolate, the chocolate solidifica-

tion

is

relatively slow

in

the printing process.

In

general, the printing

of

pure

fat

chocolate requires a low temperature environment,

and

air conditioning

can be used

to

reduce the room temperature. Ice crystal boxes can also be

purchased separately, after being frozen, they can be placed around the

printed model

to

cool down during printing.

®

Due

to

the different types

of

pure

fat

chocolate, the temperature needs

to

be

adjusted

in

the printing process. Please refer

to

the ((Chocolate

Tem-

perature Adjustment Parameter Table)) described

in

P13.

- -

--===-ii

@@@

~

j

To

~

© I

~

~I

(.__;\

Tip:

G)

The illustrations

of

products

and

accessories

in

the manual are schematic

diagrams

for

reference only;

®

Due

to the update

and

upgrade

of

the product, the actual product may

be

slightly

different from the schematic diagram. Please refer to the actual product.

Care and maintenance

Warning: Power must be cut

off

before cleaning

and

maintenance products.

1,

In

order to prolong the service life

of

the product,

it

is recommended to

use

LuckyBot customized material tube.

2.

After each

use,

use dry cloth

and

cotton swabs

to

clean the inside

and

outside

of

the base

of

the extruder

to

prevent mildew

and

agglomeration

of

residual food.

3.

After each

use,

remove the needle

and

conduct

it

with a thin needle to

ensure that the chocolate can be extruded normally when used next time.

4.

Before the Luckybot

is

installed or disassembled, the lead screw must be

moved downward to the inside

of

the equipment to prevent lead screw

thread damage.

12

FCC Warning

This device complies with part 15 of the FCC rules. Operation is subject to the following two

conditions: (1) this device may not cause harmful interference, and (2) this device must accept

any inte rference received, including interference that may cause undesired operation.

Changes or modifications not expressly approved by the party responsible for compliance could

void the user's authority to operate the equipment.

NOTE: This equipment has been tested and found to comply with the limits for a Class B digital

device, pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference in a residential installation. This equipment generates

uses and can radiate radio frequency energy and, if not installed and used in accordance with the

instructions, may cause harmful interference to radio communications. However, there is no

guarantee that interference will not occur in a particular installation. If this equipment does

cause harmful interferenceto radio or television reception, which can be determined by turning

the equipment off and on, the user is encouraged to try to correct the interference by one or

more of the following measures:

Radiation Exposure Statement

This equipment complies with FCC radiation exposure limits set forth for an

uncontrolled environment. This equipment should beinstalled and operated with

minimum distance 20cm between the radiator and your body.

•Reorient or relocate the receiving antenna.

•Increase the separation between the equipment and receiver.

•Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

•Consult the dealer or an experienced radio/TV technician for help.

Table of contents

Other Wiiboox 3D Printer manuals