INSTALLATION AND

OPERATION MANUAL

PAGE 1

© Rev. 9/2022

1.800.428.4065 TOLL FREE

| www.willoughby-ind.com

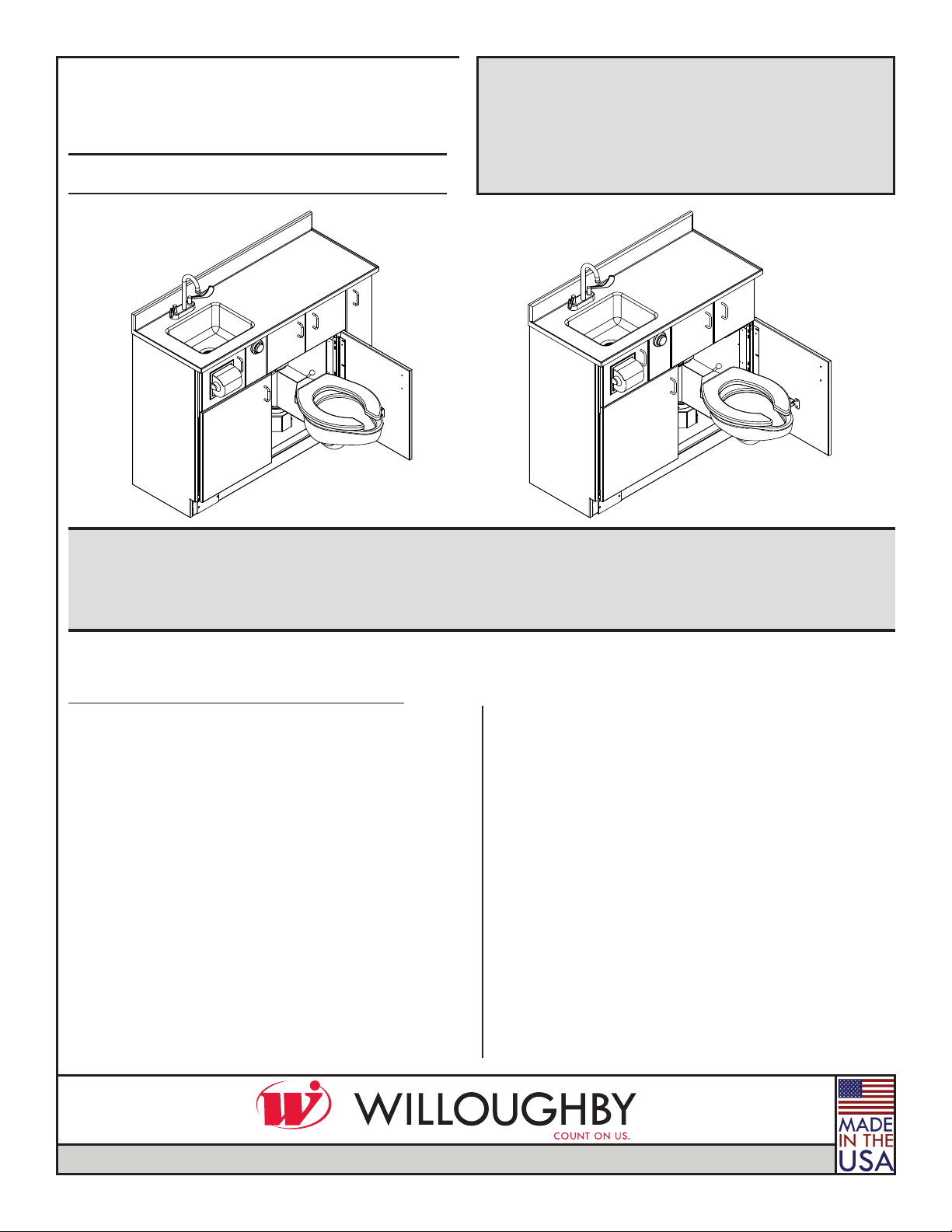

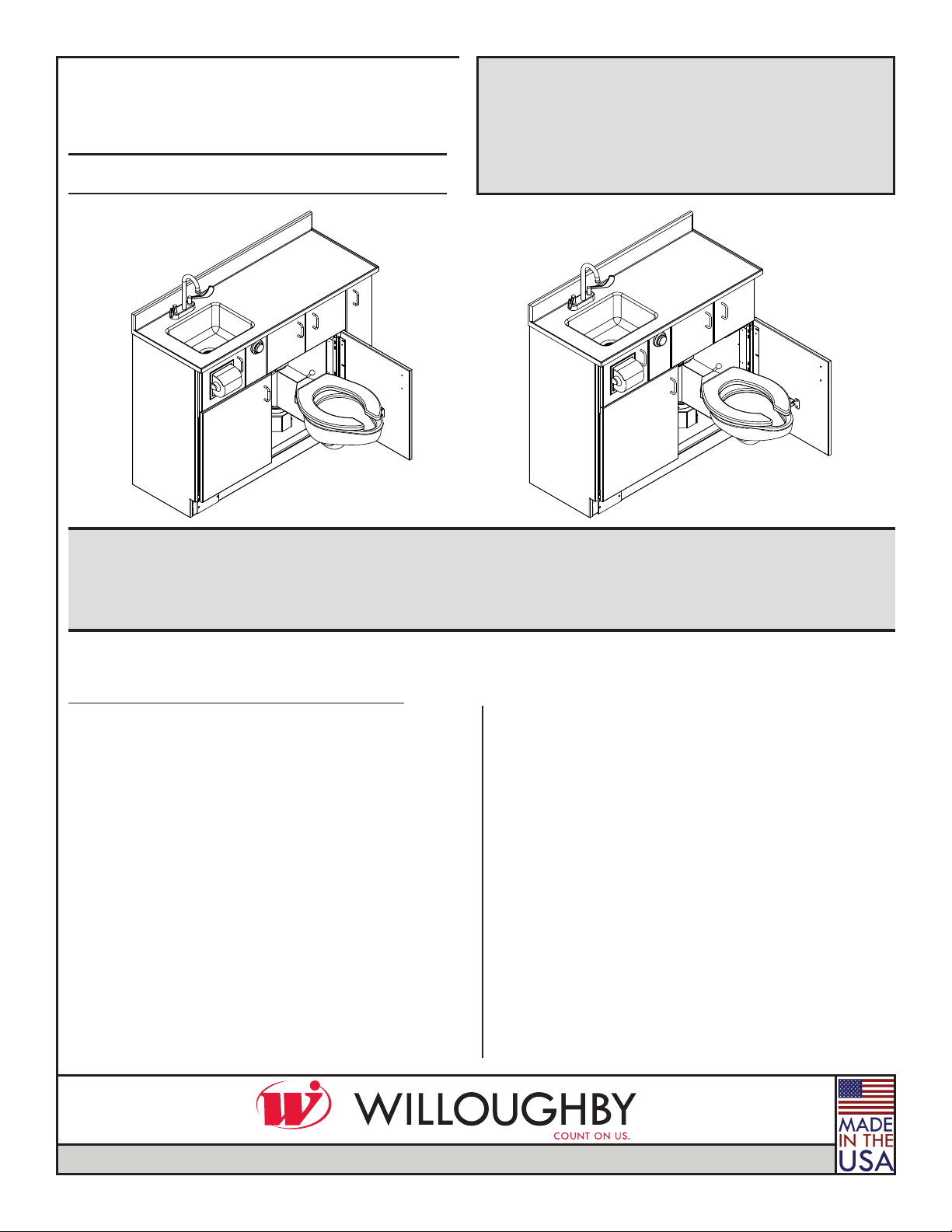

WH-1700

MODELS:

WH-1700 and WH-1750

Patient Care Units

TABLE OF CONTENTS

PRE-INSTALLATION INFORMATION....................... 3

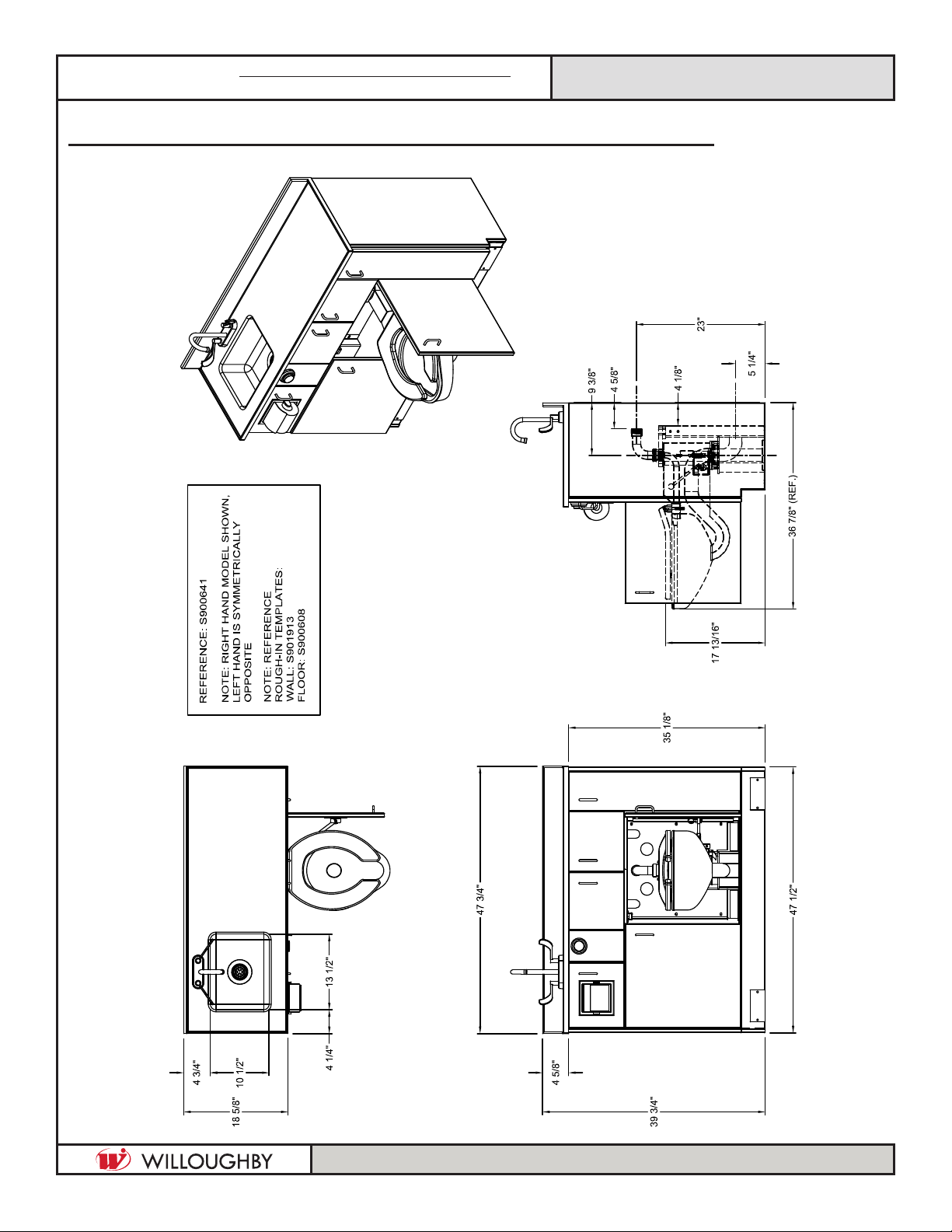

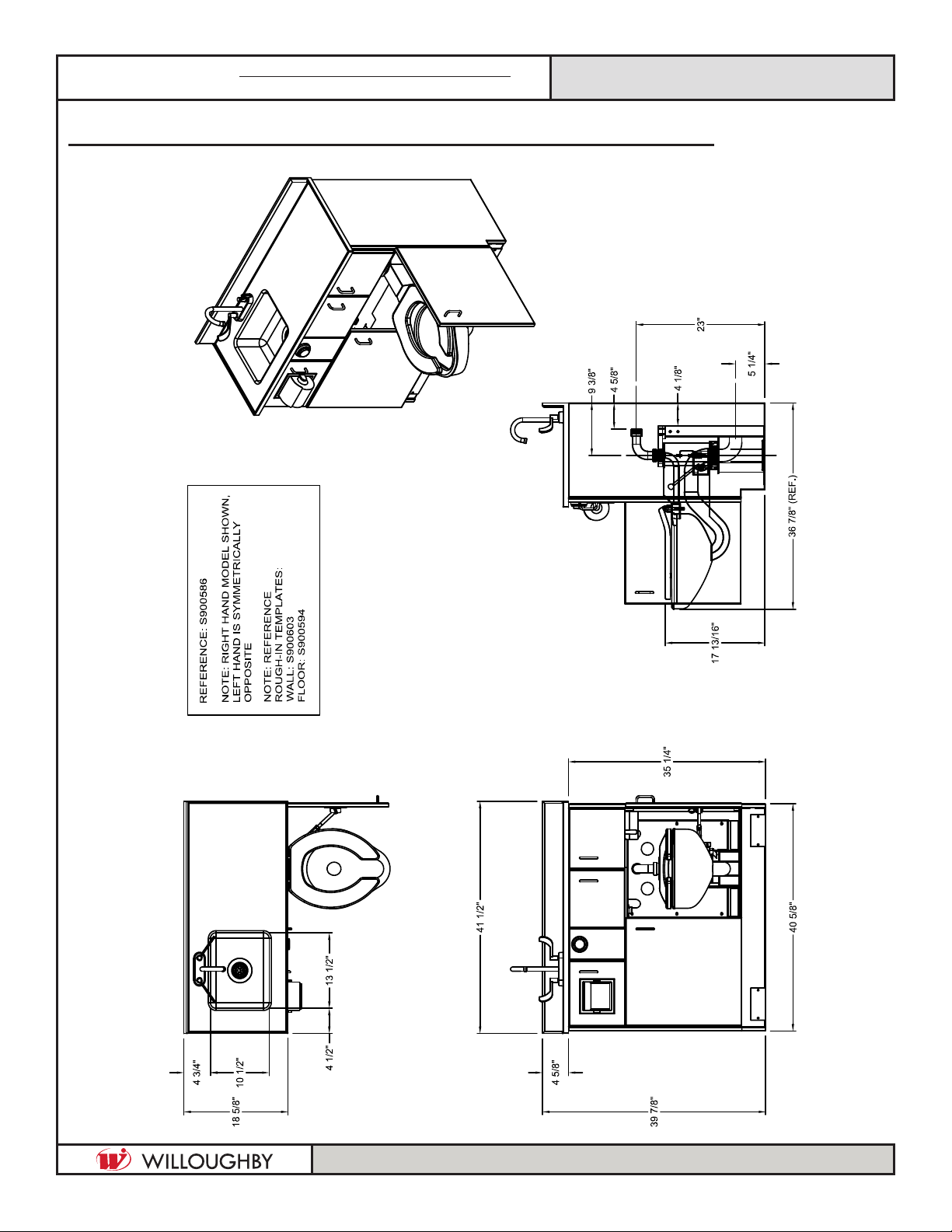

PHYSICAL DIMENSIONS .......................................... 4

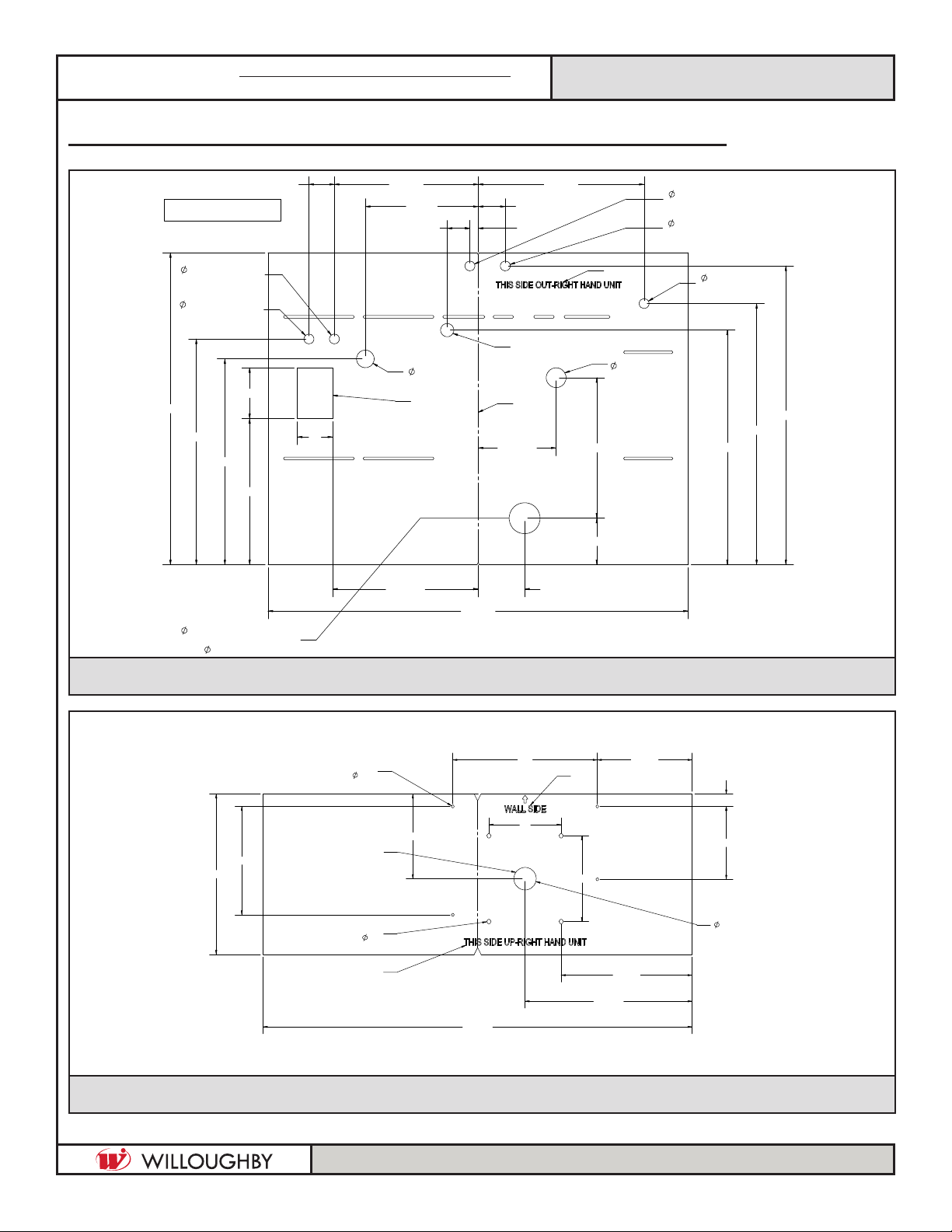

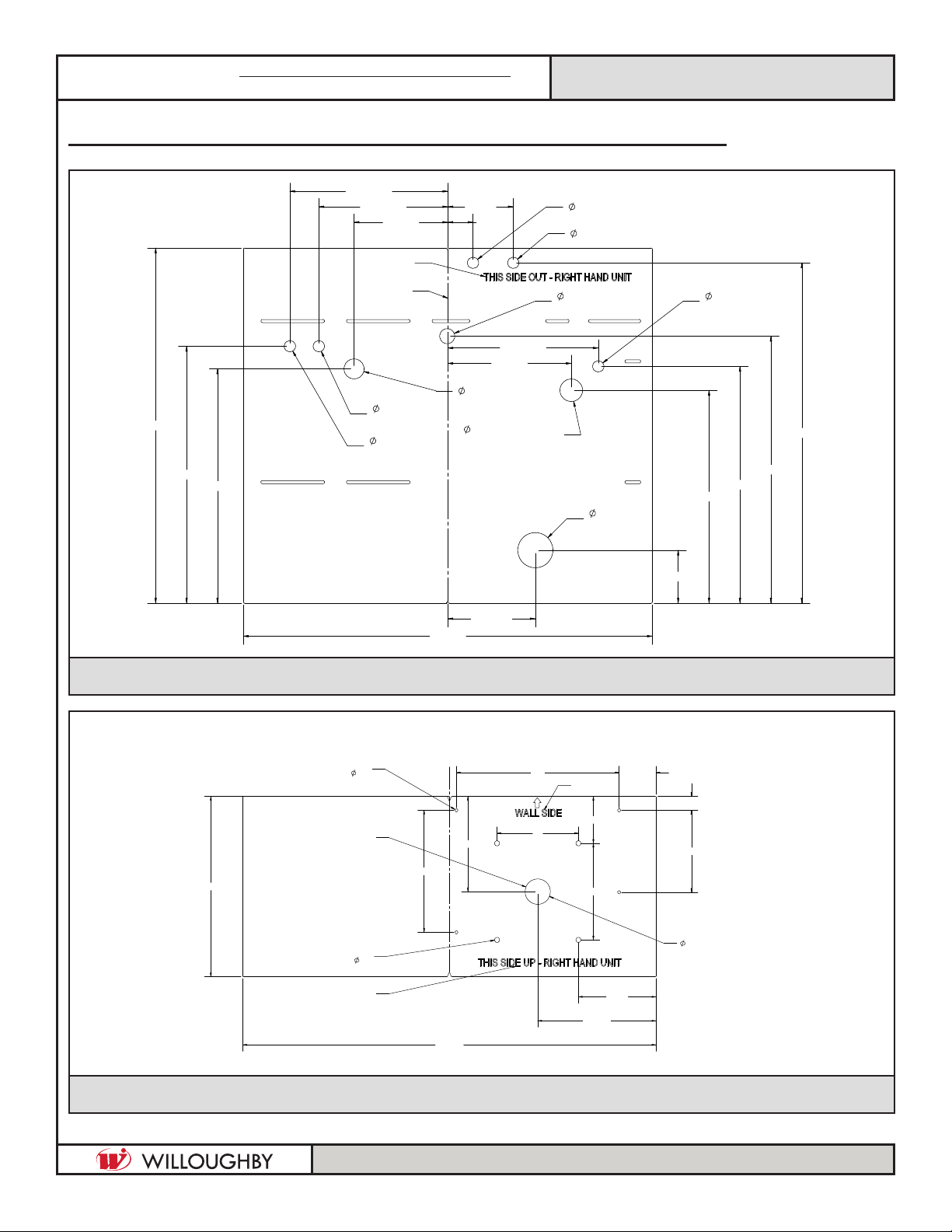

ROUGH-IN DIMENSIONS ........................................ 6

CHECKING CONTENTS............................................ 8

INSTALLATION INSTRUCTIONS .................................

Step 1: Unpack the WH-1700/1750.............10

Step 2: Install the Anchors .................................10

Step 3: Install the Toilet and

Waste Connections...............................11

Step 4: Install the Vacuum Breaker..................11

Step 5: Install the WH-1700/

WH-1750 Cabinet................................12

Step 6: Install the Solid Surface Lavatory

Top with Integral Bowl..........................12

Step 7: Install Faucet and Connect

Water Supply ........................................12

Step 8: Completing Installation ........................13

Step 9: Install and Adjust the Door Linkage...13

CARE AND MAINTENANCE ...................................14

DETAIL DRAWINGS......................................................

Swivel Toilet Assembly-L H1490-0084.......15

Swivel Toilet Assembly-R H1490-0085 ......16

WARRANTY..............................................................17

WILLOUGHBY

HEALTHCARE

PATIENT CARE UNITS

WH-1750