3

1 General

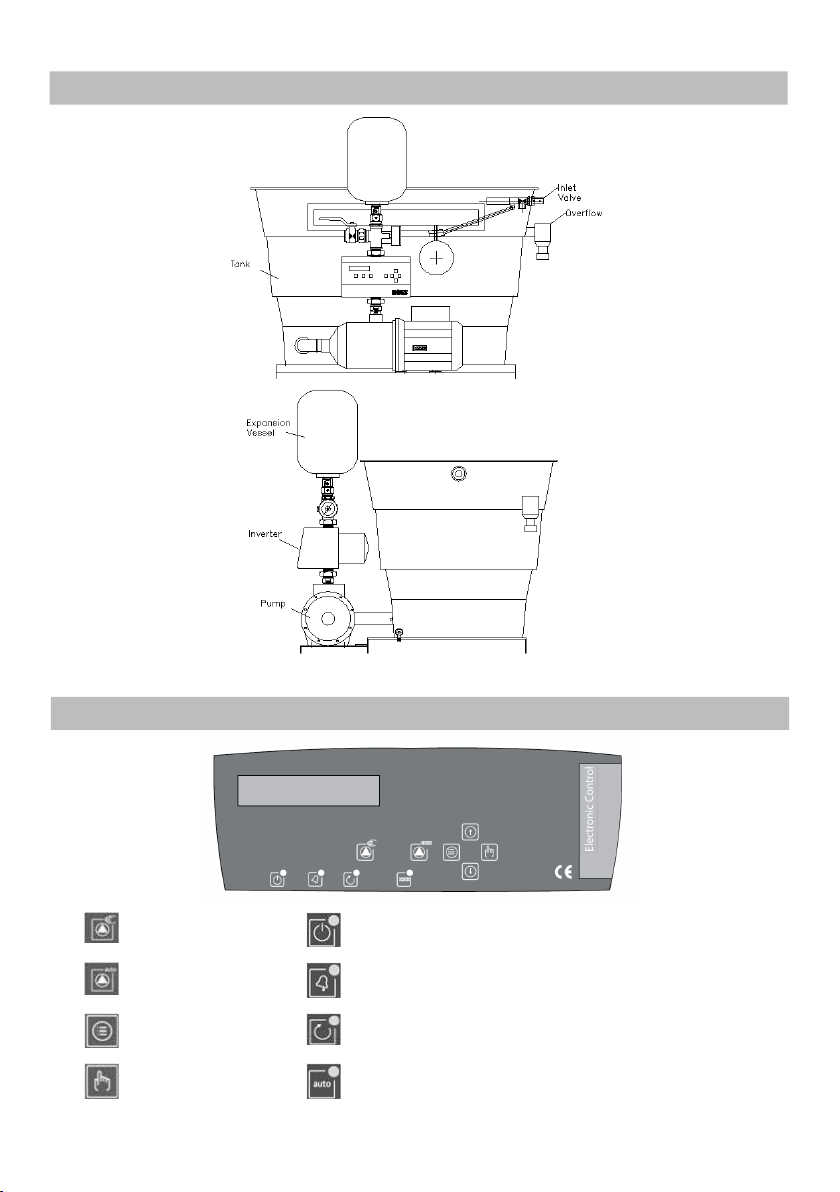

The CAT 5 booster set is a pressure boosting

system designed for raising the pressure of water

for wash down requirements. Using a single pump

xed or variable speed booster, 115 litre actual

capacity tank with category 5 backow prevention

via an AB airgap.

ATTENTION! Installation and commissioning by

qualied personnel only!

NOTE – An onsite audit must be completed once

installed to ensure there are no contributing

factors that may compromise the air gap (ie.

foaming, splashing)

2 Safety

Any works carried out on CAT 5 booster sets must

be completed by a qualied person. Failure to

comply to any of the information in this manual

may cause potential hazards to people and the

environment and may void the warranty.

Operators must be fully aware of all functions of

the boosterset and any risks associated. For more

information on training please contact Wilo Ph:

01283 523 000

WARNING! Local regulations must be complied

to when installing and maintaining the booster

set

2.1 Symbols and Signals

DANGER! Extremely dangerous situation. Non-

observance could cause death or serious injuries.

WARNING! The user may suffer from injuries

(serious). The mention of warning involves that

personal (serious) injuries may happen when

precautions are not observed.

ATTENTION! Damage could be caused to the

pump or installation. The mention of attention

is used to indicate that by ignoring the relevant

safety instructions, damage could be caused to

the pump or its operation.

NOTE - Useful remark for product handling. Any

possible difculty is mentioned.

2.2 Modication and Spare Parts

Modications to the booster are prohibited and

will invalidate the warranty. Wilo Approved spares

must be used at all times. For information on

spares see Table 4 of this manual

3 Transport and Storage

CAT 5 booster must always be transported

by pallet and moved with appropriate lifting

equipment. Booster must be stored in a dry

environment between –25 °C to +55 °C.

NOTE – If stored for future installation the lm

wrapping must not be removed and must be

stored in a dry environment

4 Description and Operation

4.1 MHI PS-EM (Single Phase Fixed Speed)

4.1.1 Operating Mode

CAT 5 PS-EM is a xed speed booster set which

is controlled with a Hand Off Auto (HOA) box via

a pressure switch. When the switch is turned to

Hand Mode the set will run at full speed constantly

and will not turn off. When the switch is turned to

Auto Mode the set will run until the pressure set

on the pressure switch has been reached. Once the

pressure has been achieved the set will run until

the programmable timer times out

4.1.2 Operating Features

•Programmable pressure switch – Sets the

pressure at which the timer starts via dials on the

front of the switch (Fig 6)

•Programmable timer – Sets the length of time the

booster will run once the set pressure has been

achieved. Programmable in the HOA box (Fig 6)

•Low water cut out switch – Turns the booster off

instantly once the water level drops below a set

level to stop air from entering the pump (Fig 1)

•Volt Free Contacts (VFC) – Normally open and

normally closed contacts signal if the pump has

tripped under high current (Fig 1)

NOTE – Programmable timer is inside the HOA

box and is factory set at 120 seconds to reduce

start/stop frequency of the set.