Cleaning the interior components

Electrical Shock Hazard

Disconnect power before cleaning.

Replace all panels before operating.

Failure to do so can result in death or electrical shock.

1.

Unplug ice maker or disconnect power.

2. Open the storage bin door and remove any ice that is

in the bin.

3. Remove the ice retainer baffle by flexing it and sliding if

off the studs.

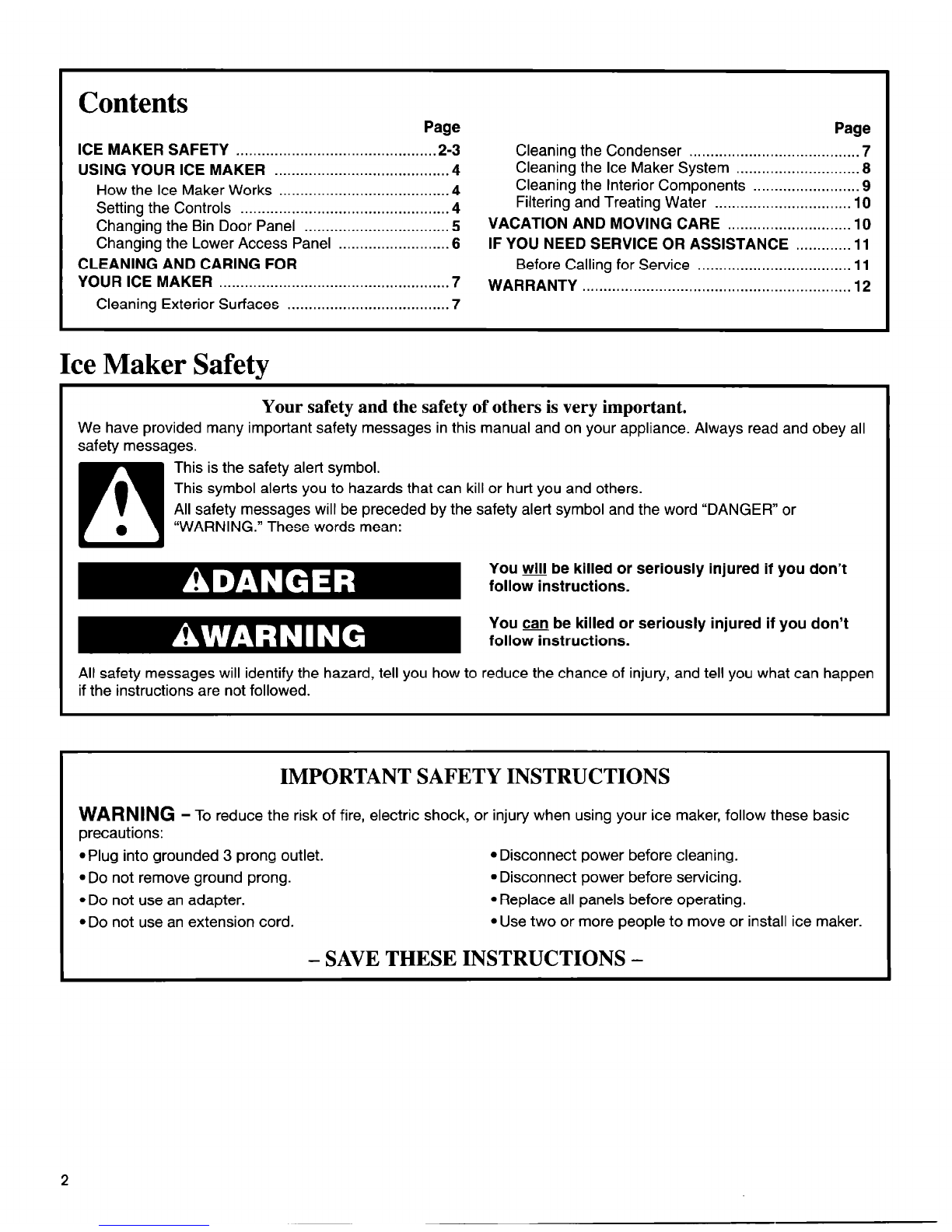

4. Remove the ice cutter grid by unscrewing the 2 thumb

screws, sliding the grid forward, and unplugging the

electrical wire harness.

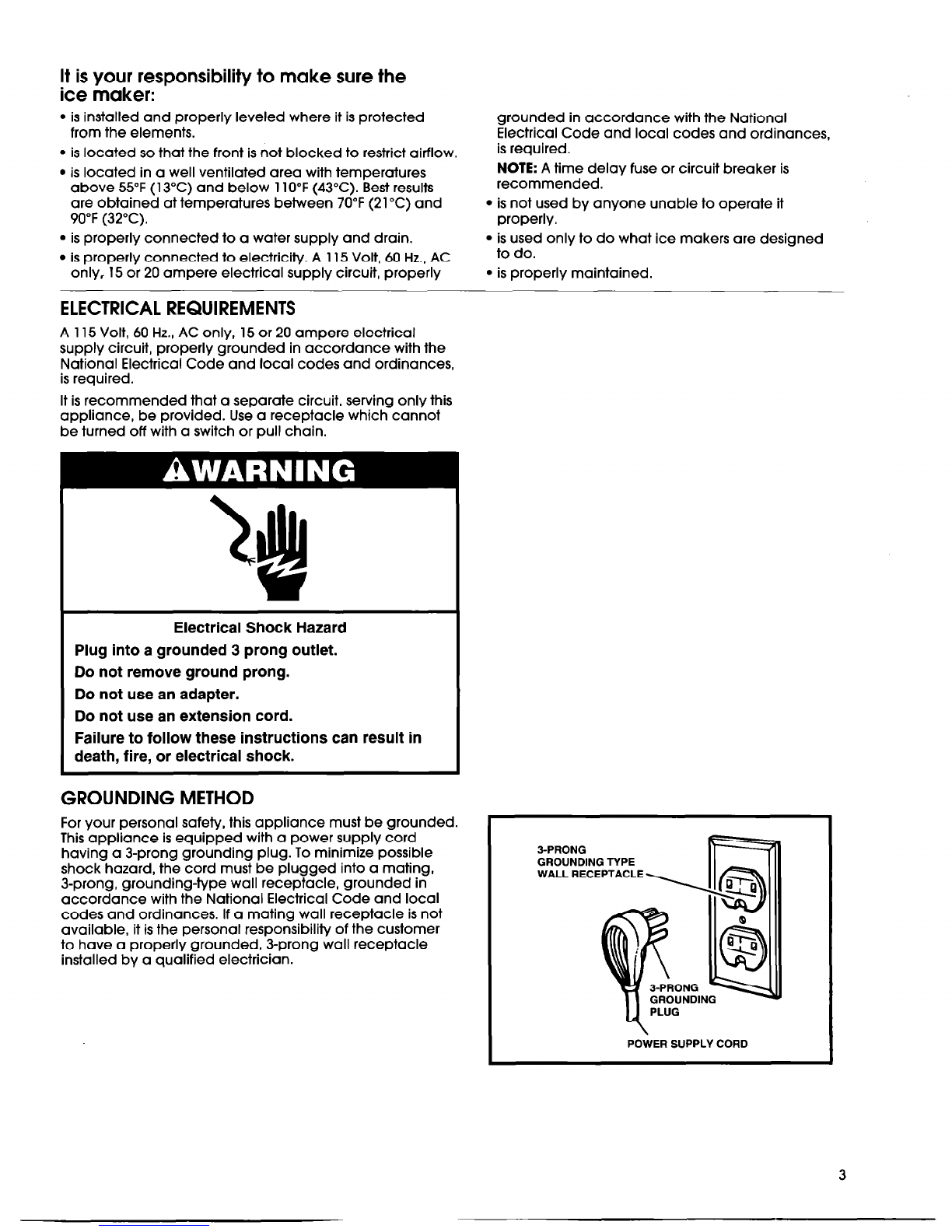

5. Remove the water pan by unscrewing the

2 thumb screws.

END CAPS

7. Remove the water distributor from the freezing

plate. It is held in place by rubber end caps,

Remove the inlet hose and clean all water

distributor holes and the small orifice in the inlet

side of the water distributor. When replacing the

water distributor, make sure the end caps are

located in the freezing plate holes and that the

water distributor holes face down.

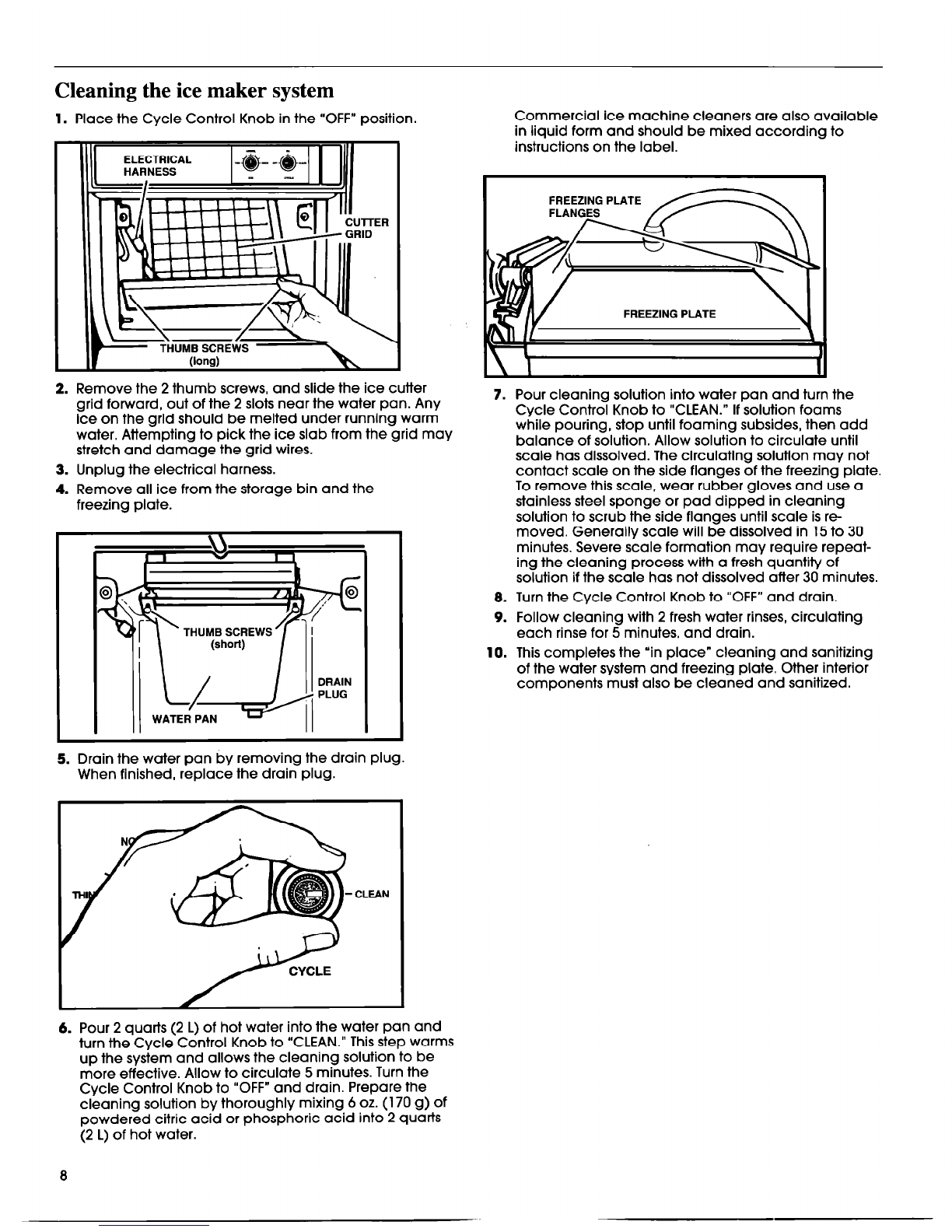

8. Wash the

interior components

(ice retainer

baffle, cutter grid, water pan, inlet hose, and

water distributor) and the storage bin, door

gasket, and ice scoop with mild soap or

detergent and warm water. Rinse in clean

water. The components should also be cleaned

in a solution of 1 tablespoon (15 mL) of house

hold bleach mixed with 1 gallon (3.8 L) warm

water.

DO NOT WASH PLASTIC PARTS IN THE

DISHWASHER. They cannot withstand

temperatures above 145°F (63°C).

9. Replace the interior components (water distribu-

tor, inlet hose, water pan, cutter grid, and ice

retainer baffle).

10.

Check the following:

l

Hose from water valve is in the water pan.

l

Rubber drain plug is in the water pan.

l

Water distributor is seated and holes are

facing down.

l

Hose is connected to the pump and the

water distributor.

l

Hose from water pan is inserted into the

storage bin drain opening.

11.

Reconnect the electrical harness, and slide

cutter grid into place. Tighten the thumb screws.

12. Plug in ice maker or reconnect power.

13. Reset the controls, see “Setting the controls” on

page 4.

6. Remove the hose from the water pump.

9 1