32

Brine: Under certain concentration and flow rate conditions, brine flow

through entire resin bed, then the saturated resins will resume their

softening capacity.

Rinse: Rinse the resin bed to remove the residual regenerant (salt) in it

after Brine step until the water from outlet contains no regenerant; rinse

could also impact the resin bed for a better softening effect.

Fill: Refill water to brine tank to dissolve salt for the next regeneration.

PE Brine Tank

■ Refill water and salt meet each other in the brine tank, and the salt will

dissolve continuously to water through natural convection until the

water is saturated by salts.

Operation

This product should be able to put in normal use right after the complete

installation and a regeneration test; any other operations are not

necessary unless power supply is cut off accidentally;

The soften unit should be installed and prepared by qualified person, any

other operations are not necessary while keeping power on all the time

and remaining enough salt in brine tank. The only requirements for

installation are three water pipe ports (inlet, outlet, drain) and power

supply.

Fill resin tank with water (Initial)

■Set the control into the backwash position, then open water supply

valve very slowly to approximately the 1/4 open position and let water

flow slowly into the resin tank ( if open too rapidly or too far, resin

may be lost). When all of the air has been purged from the tank (water

begins to flow steadily from the drain), open the main supply valve to

the full position.

■ Drain until the drain water is clear.

■ Shut off water supply and let the unit stand for about five minutes to

escape all trapped air from the tank.

Refill brine tank

■ Manually initiate a whole regeneration cycles after resin tank filling (

see Appendix) to fill appropriate water to brine tank.

ЎSalt level should be higher than water level at first time. There should be

enough solid salt at anytime.

It is recommended to install a bypass system to ensure water supply in any

special cases, such as softener failure, maintenance, etc.

Cautions

1) Without reading and truly understanding the contents of this user

manual, please DO NOT perform any operations on the control valve.

2) Strictly prohibit leaning position when shipping, installing and using

this product: Otherwise, it will be damaged inside.

3) During regenerate time, water from tap will NOT be softened. It is NOT

recommended to use water during regeneration; otherwise, a negative

effect on the regeneration result will occur;

4) Initial a regenerate cycle after being inactivated in a long period of

time, and then turn on the tap for several minutes before resuming

normal use;

DO NOT disconnect power during service time to keep the timer run

normal that controls the regeneration function;

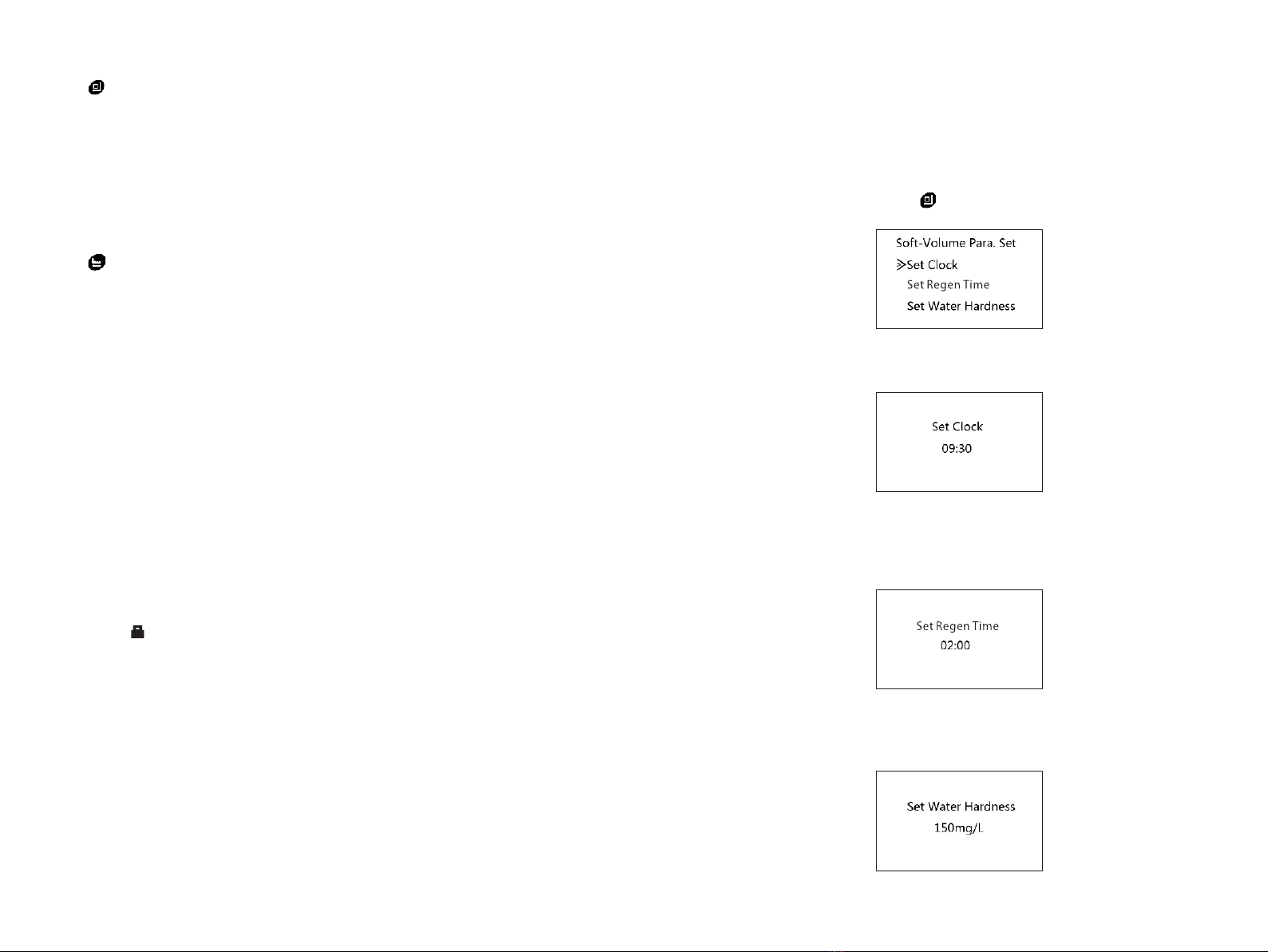

5) If the hardness of raw water dramatically changes, change the Water

Hardness in the User Setting menu.

6) Hot water could cause severe damage to the softener system; for water

boiler and water heater users, ensure the total-run of the piping between

the softener and the boiler is not less than 3 meters; it is recommended

to install a check valve between the filter and the boiler if unable to

meet the required piping length.

7) The input water pressure must be between 0.1 to 0.6 Mpa, no negative

water pressure allowed.

8) No chemical allowed at the inlet and outlet connecting sectors. No

excessive force which can damage the plastic conjunction parts should

be applied by any tools. Besides the machine, spare part connection

material doesn't include in scope of manufacture's warranty.

9) The required environmental temperature for softener is 33.8~102.2°F.

Please protect the softener from frozen.

10) Please set up a waterspout on the floor nearby the softener in case of

any leaking accidents.