- Misuse of this machine can cause serious injury.

- For safety, machine must be set up, used and

serviced properly.

- Read, understand and follow instructions in the

Operating Instructions and Parts Manual which was

shipped with your machine.

When Setting up Machine:

- Always avoid using machinein dampor poorly

lightedworkareas.

- Always be sure the machine support is securely

anchored to the floor or the work bench.

When Using Machine:

- Always wear safety glasses withside shields (See

ANSIZ87.1)

- Neverwear loose clothingorjewelry.

- Never overreach - you may slip and fall.

When Servicing Machine:

- Always disconnect the machine from its electrical

supply while servicing.

- Always follow instructions in Operating Instructions

and Parts Manual when changing accessory tools

or parts.

- Never modify the machine without consulting

Wilton Corporation.

You - the Stationary Power Tool User -

Hold the Key to Safety.

Read and follow these simple rules for best results

and full benefits from your machine. Used properly,

Wilton's machinery is among the best in design and

safety. However, any machine used improperly can

be rendered inefficient and unsafe. It is absolutely

mandatory that those who use our products be

properly trained in how to use them correctly. They

should read and understand the Operating Instructions

and Parts Manual as well as all labels affixed to the

machine. Failure in following all of these warnings

can cause serious injuries.

Machinery General Safety Warnings

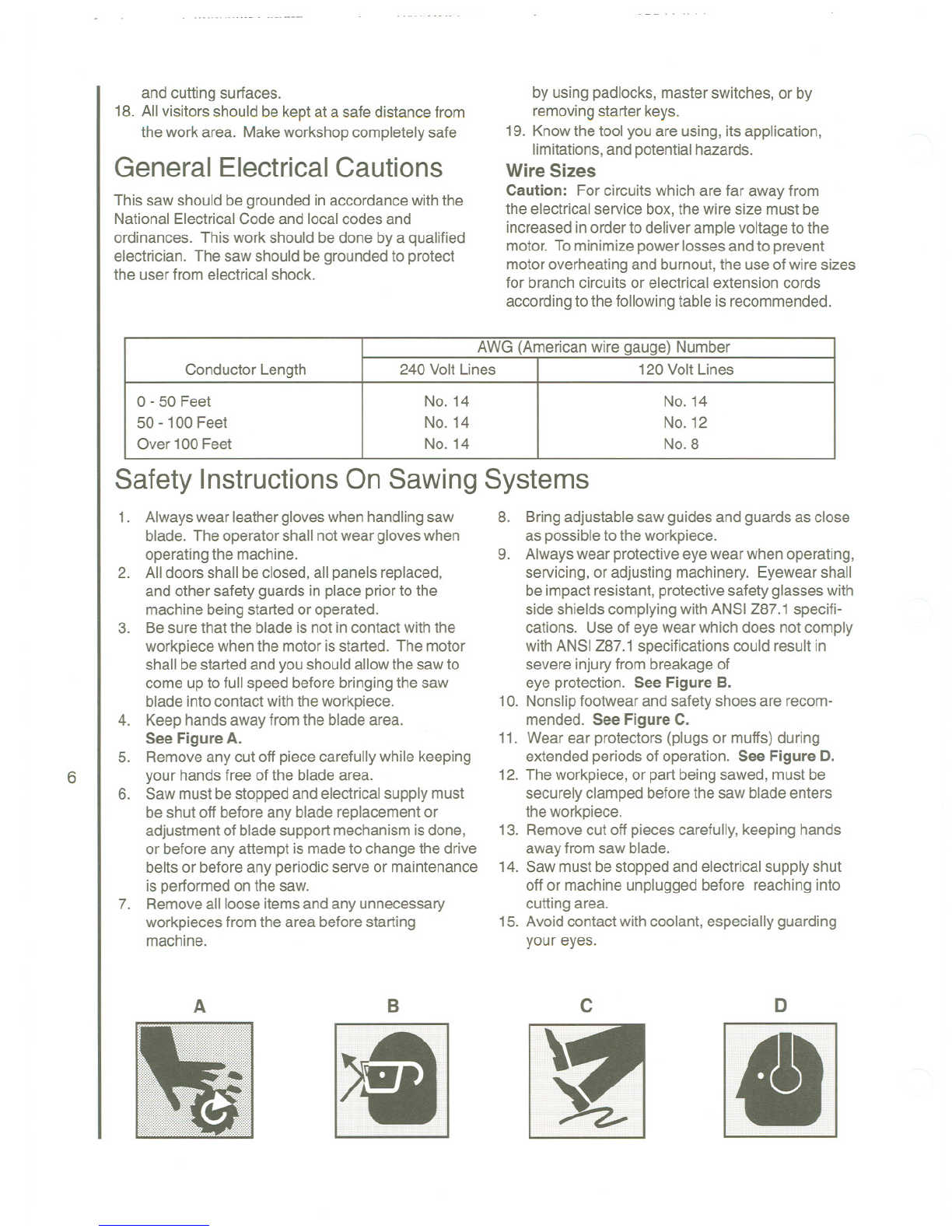

1. Alwayswear protectiveeyewear when operating 8.

machinery. Eye wear shall be impact resistant,

protectivesafety glasseswith sideshieldswhich

comply with ANSI Z87.1 specifications. Useof

eye wear which does not comply with ANSIZ87.1

specifications could result in severe injuryfrom

breakage of eye protection.

2. Wear proper apparel. No loose clothingor

jewelry which can getcaught inmoving parts.

Rubbersoledfootwear isrecommendedfor

bestfooting.

3. Do notoverreach. Failureto maintain proper

working position can cause you to fall intothe

machineor cause your clothingto get caught

pullingyou intothe machine.

4. Keep guards in place and in properworking

order. Do notoperatethe machinewith

guardsremoved.

5. Avoid dangerousworkingenvironments. Donot

use stationary machinetools inwet or damp

locations. Keepwork areas clean andwell lit.

6. Avoid accidental starts by beingsurethe start

switch is OFF before plugging inthe machine.

7. Never leavethe machinerunningwhile unat-

tended. Machineshallbeshutoffwheneverit

is not in operation.

Disconnectelectricalpower beforeservicing.

Whenever changing accessoriesor general

maintenanceis done onthe machine, electrical

powertothe machinemustbedisconnected

beforework is done.

9. Maintainall machinetoolswithcare. Followall

maintenanceinstructionsfor lubricatingandthe

changingof accessories. No attemptshall be

madeto modify or have makeshiftrepairsdone to

the machine. This notonlyvoids the warranty but

also rendersthe machineunsafe.

10. Machinery mustbe anchoredto the floor.

11. Securework. Use clampsor a vise to hold work,

when practical. It is safer than using your hands

and itfrees both handsto operate the machine.

12. Neverbrush away chipswhile the machine is in

operation.

13. Keepwork area clean. Cluttered areas invite

accidents.

14. Removeadjustingkeysandwrenchesbefore

turning machineon.

15. Usethe righttool. Don't force a tool or attach-

mentto do a job itwas not designedfor.

16. Useonly recommendedaccessoriesand follow

manufacturersinstructionspertainingtothem.

17. Keep hands in sight and clear of all moving parts

5