The ME2100 Fine Fuel Moisture Meter is a versatile tool that can be used both in the field and in the laboratory.

Its primary purpose is to measure the moisture content of fine fuels, such as leaves, twigs, and grasses.

The moisture in these fine fuels is one of the most important factors in determining fire intensity, the forward rate

at of spread and the potential of forward spotting. The meter provides this fine fuel data, which is applicable to

wildfire behaviour and to the management of prescribed burns.

The ME2100 meter also has a Lab-Mode with a higher degree of accuracy than the field mode; it is capable of

providing more precise measurements in controlled laboratory settings. The meter has been designed to meet the

needs researchers studying forest ecology or investigating the effects of different moisture levels on fire behaviour.

The ME2100 Fine Fuel Moisture Meter is a valuable tool for officers involved in wildfire management and

researchers studying forest ecosystems.

The conventional method of determining the moisture content of fine fuels through sample collection and

oven-drying is slow, energy-consuming, and not practical for real-time field use. Diurnal and site-to-site variations,

as well as live-fire variations, require frequent measurements across a range of locations over the course of a fire

to ensure safety and effective fire management.

The ME2100 Fine Fuel Moisture Meter offers a fast and accurate alternative to the conventional method. By

measuring the resistance of fine fuel samples, it can provide a quick and reliable estimate of moisture content

without the need for samples being sent to a laboratory and dried for up to 24hrs to determine the % of Oven

Dried Weight (%ODW). The speed of measurement by the ME2100 makes it especially useful in the case of

prescribed burns, where fine fuel moisture content is a critical factor in the decision to burn or not to burn. This

also applies to wildfires where fine fuel moisture content is a critical factor in determining the rate of the fires

spread and subsequent deployment of resources.

The principle of the meters operation is the measurement of the resistance of the sample couple with the application

of a predetermined coefficient. The coefficient is based on the fuel type and its condition. To achieve the accuracy

of the %ODW, the meter is able to measure resistances in excess of 10 TOhms (10x10 ) which corresponds to fuel

moisture contents as low or lower than 2% ODW. (The usable range of the meter is approx. 3 – 200% ODW).

It should be noted that cleaning the top surface of the test cell and keeping it clean is the most critical factor in

achieving accurate readings. In measuring the moisture in a sample, the presence of mineral nutrients in the leaf

matter can vary greatly. The meter is designed to factor out these nutrients, however even the slightest amount of

residue on the top surface of the test cell can cause inaccurate readings.

The meter can store the data on up to 600 samples (Moisture Content, location identifiers, time and date) This data

can be downloaded to a PC if required.

The ME2100's meters ability to store data can also be very useful when in Lab-Modes where it can provide researchers

with the flexibility to gather accurate data in both controlled laboratory settings and real-world field conditions.

The meter is powered by a lithium LiFePO4 battery which will operate the meter continuously for over 20hrs before

recharging is necessary. A feature of the meter to conserve energy is that it will turn itself off after 20 minutes, if no

key has been pressed. Pressing the on/off switch will reactivate the unit. In addition, as each reading only takes

a 1-2 minutes, in the prescribed burn/fire period, recharging may only be required once a month.

However the meter can’t be over charged, so a routine of charging weekly during the season maybe useful.

Due to variations in the moisture content within a leaf and between leaves, the sample must be homogenise before

testing. A pair of multi-bladed scissors and a grinder is provided in the kit, these must be used, to ensure

accurate measurements.

In addition, sample moisture content variation, even within a small area of forest, requires 2 or 3 sample from the site

to be measured and average to achieve best practise of moisture content determination on the site.

Overall, the ME2100 Fine Fuel Moisture Meter is a valuable tool for fire management and forest ecology research,

offering a faster, more efficient and accurate alternative to traditional methods of measuring fine fuel moisture content.

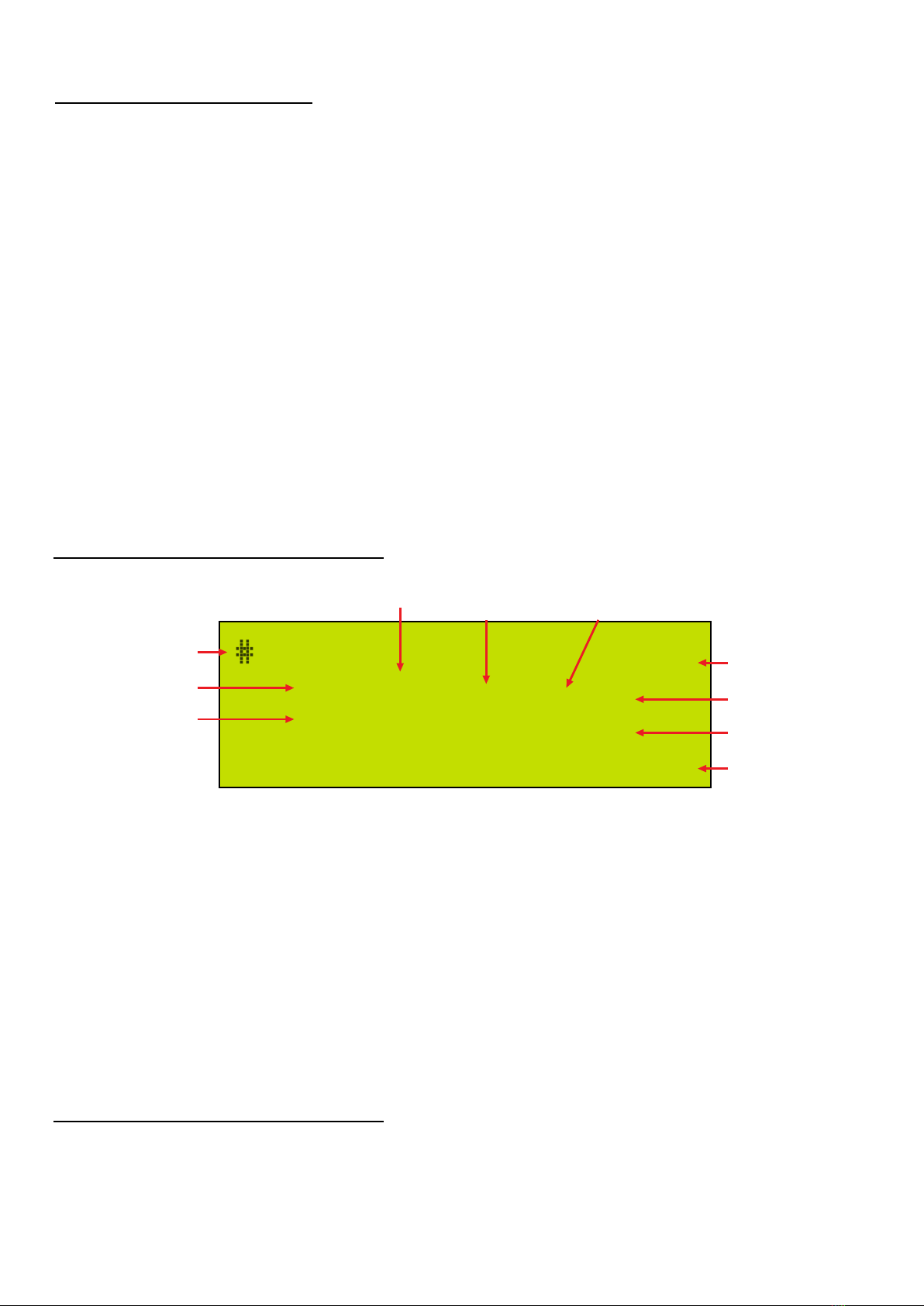

1.Description of the Meter

Wiltronics Research Pty Ltd 4561 DC1V1

12