5REV B 60706-199

WARNING: PERSONAL INJURY & EQUIPMENT DAMAGE

Trailer may tip over and cause injuries if wheels are not spaced far

enough apart.

THREE-POINT HITCH KIT

Optional 3-Point Hitch Part Number TPH241

WARNING: PERSONAL INJURY & EQUIPMENT DAMAGE

When using the 3-point hitch assembly all three points must be

attached to the tractor. Failure to do so will cause the generator to tip

when lifting it damaging both the t-bar and the generator.

A. The three point hitch must be attached to the tractor at all times

during operation.

B. When operating the generator the three point hitch and generator

mustbesittingonatlevelground.Allfourdeckpadsmustbein

constant contact with the ground at all times. This will reduce the

vibration in both the generator and the tumbling bar.

C. For safety the generator must be bolted to the three point hitch deck

using all four mounting bolts.

Page 3 60706-180

0310-00

B. The foundation must be solid enough to absorb generator

starting and reflected load torque during operation.

C. The foundation surface should be flat.

D. Space is required around the generator for mounting

switching devices, making connections, and for servicing.

E. The generator mounting bracket must rest evenly and

firmly on the foundation. Install shims if necessary to even

out the foundation under the mounting pads then bolt the

generator firmly in place.

TRAILER MOUNTING

Mount the generator on a trailer if you plan to use it as a

portable power source. When selecting or building a trailer to

mount the generator, consider the following points:

A. The trailer construction must be strong enough to support

the generator.

B. The design of the trailer must enable the trailer to remain

stable during operation, and to resist tipping caused by

generator starting and reflected load torque.

WARNING: Personal Injury & Equipment Damage

TRAILER MAY TIP OVER AND CAUSE INJURIES IF

WHEELS ARE NOT SPACED FAR ENOUGH APART.

Optional Trailer Part Number TDM75

C. The trailer height and mounting position of the generator on

the trailer should enable aligning the drive shaft (tumbling bar)

in a straight or nearly straight line between the power take-off

and generator input shafts. Misalignment must be less than 10

degrees during generator operation, even though the mechani-

cal design of the tumbling bar would allow greater misalign-

ment.

D. The generator mounting area of the trailer bed should be

flat.

All four generator mounting pads must rest firmly on the trailer

bed. Install shims if necessary to even out the bed under the

mounting pads, then bolt the generator firmly in place.

WINCO THREE POINT HITCH

Optional 3-Point Hitch Part Number TPH240

WARNING: Personal Injury & Equipment Damage

WHEN USING THE 3-POINT HITCH ASSEMBLY ALL THREE

POINTS MUST BE ATTACHED TO THE TRACTOR. FAIL-

URE TO DO SO WILL CAUSE THE GENERATOR TO TIP

WHEN LIFTING IT DAMAGING BOTH THE T-BAR AND THE

GENERATOR.

A. The three point hitch must be attached to the tractor at all

times during operation.

B. When operating the generator the three point hitch and

generator must be sitting on flat level ground. All four deck

pads must be in constant contact with the ground at all

times. This will reduce the vibration in both the generator

and the tumbling bar.

C. For safety the generator must be bolted to the three point

hitch deck using all four mounting bolts

ELECTRICAL CONNECTIONS

CAUTION:

Only qualied electricians should install electrical wiring. Wiring must

conform to all applicable national, state, and local codes. (Reference:

National Fire Protection Association Manual No. 70, National Electrical

Code.)

DANGER: PERSONAL INJURY:

If the generator is to be used as a standby power source,, a manual

transfer switch must be installed to separate the generator and the

commercial power lines. The switch must isolate the generator from the

commercial power lines and the load when the generator is on standby,

and must isolate the commercial power lines from the load and the

generator when the generator is supplying power. See the following

diagrams.

A properly rated and installed double throw manual power isolation

transfer switch must be used with a standby generator. The transfer

switch isolates the load from the power line and allows you to safely

operate your loads without endangering the power line repair crew. See

previous diagrams

The load, connected to the normal terminals of the transfer switch, is

energized by the normal power line when the switch is in the normal

position. The generator, connected to the emergency terminals of the

switch, furnishes power when the switch is in the emergency mode

position.

Therearetwowaystoinstallamanualtransferswitch.Therstshown

on the left side of page 6 is to install the switch between the watt-hour

meter and the normal distribution panel. As with any system you must

install an entrance rated breaker before the manual transfer switch. The

manual transfer switch must in all cases be equal to or greater than the

rating of the entrance rated breaker.

The second way to install the system is to purchase and install an

emergency distribution panel and move the circuits you wish to back

up to the new distribution panel. In this case the manual transfer switch

only has to be sized to the amperage of the circuit breaker in the main

distribution panel that is feeding it. See the right hand drawing of the

previous diagrams

Beforedecidingwhichsystemtoinstall,rstdeterminewhichloadsyou

can safely run on your PTO generator and the cost of buying a large

manual transfer switch versus the cost of a smaller switch and the

additional distribution panel.

The only assembly work required after unpacking the generator is to

assemble the load disconnect plug, which is contained in a bag in the

subpack carton packed in the generator crate.

The bag contains an instruction sheet, 2 plug bodies, four contacts,

two handle and the hardware to assembly the disconnect plug. You will

needtopurchasetheappropriatelengthofnestrandedcopperwire

for your application in order to complete the assembly of the disconnect

plug. DO NOT USE SO CABLE - USE SINGLE LEAD WELDING

CABLE

A #4 Neoprene/THHN wire size is recommended.

If you require different inserts or contacts for local code,

WINCO has a variety of different inserts and contacts available.

Contact the factory at 507-357-6831 for pricing.

Page 2 60706-199

1005-00

Description

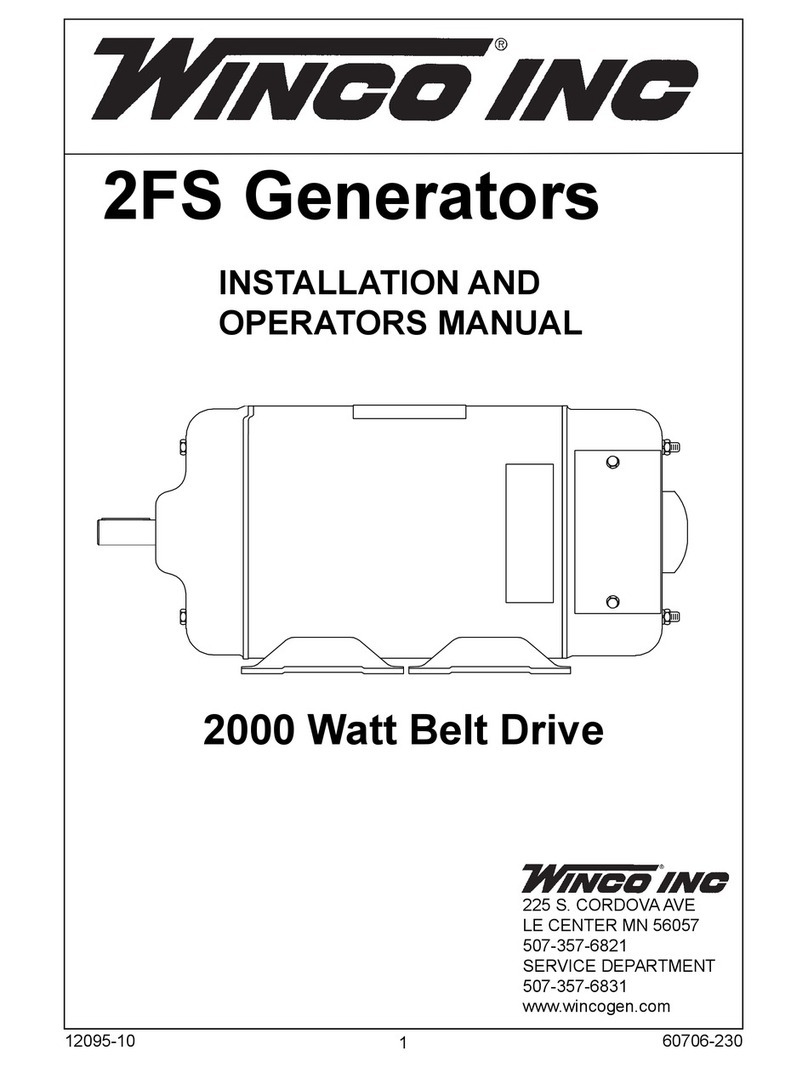

The WINCO rotating armature power take-off generators are

designed primarily for farm use as a standby electrical power

supply, utilizing the power take-off of a tractor or truck as the

prime mover. This PTO drive generator will provide, 120/240V

single phase, 60Hz electrical service when properly driven.

NOTE: The prime mover which drives the generator must be

capable of delivering approximately 2 HP per 1000 watts

output from the generator. Observe input RPM specifications.

The generator may be foundation mounted for use as standby

power source, or trailer mounted, and used as portable

electrical power sources for areas where commercial power

is not readily available, such as out buildings.

This generator includes a color coded voltmeter to warn

against high or low voltage, three output power receptacles,

an overload protection circuit, and an electronic excitation

circuit. To reduce maintenance problems, the coupling

between the generator input shaft and rotor consists of

precision helical gearing rather than a chain link drive. The

input shaft is a 1 1/8 in. diameter smooth shaft with a keyway

and center drilled for a roll pin. Both must be used at all

times.

The factory thoroughly tests each generator before shipment.

All are continuous duty rated.

IMPORTANT: THE MANUFACTURER STRONGLY RECOM-

MENDS RUNNING THE GENERATOR UNDER LOAD AT

LEAST ONCE A MONTH IN ORDER TO EVAPORATE ANY

ACCUMULATED MOISTURE CONDENSATION.

UNPACKING

CAUTION: Equipment Damage

DO NOT invert generator during unpacking. The Gearcase

contains oil which will leak out if inverted during unpacking.

Unpack the generator as follows:

1. Remove the carton.

2. Examine the unit for damage.

3. Find the small subpack carton packed in the large carton.

Be careful not to throw away the subpack carton with the

large carton.

4. Open the subpack carton and make sure it contains:

a. Generator instruction manual

b. Load disconnect plug (disassembled, in bag)

5. Remove the four bolts which hold down the generator feet

to the pallet.

6. Lift the generator from the pallet by means of the lifting eye

on the top of the generator.

7. Inspect the generator carefully for freight loss or damage.

If loss or damage is noted at time of delivery, require that

the person making the delivery make note of the loss or

damage on the freight bill, or sign the consigner’s memo

of the loss or damage. Contact the carrier for claim

procedures.

When loss or damage is noted after delivery, segregate the

damaged material, and contact the carrier for claim proce-

dures.

“Concealed damage” means damage to the contents of a

package which is not evident when the package is delivered

by the carrier, but which is discovered later. The carrier or

carriers are responsible for merchandise lost or damaged in

transit. The title to the goods rests with the consignee when

the goods are shipped FOB factory, and only the consignee

can legally file claims. Two years are allowed in which to file

suit after a claim is disallowed in writing by the carrier.

Assembly

The only assembly work required after unpacking the genera-

tor is to assemble the load disconnect plug, which is con-

tained in a bag in the subpack carton packed in the generator

crate.

The bag contains an instruction sheet, 2 plug bodies, four

contacts, two handle and the hardware to assembly the

disconnect plug. You will need to purchase the appropriate

length of fine stranded copper wire for your application in order

to complete the assembly of the disconnect plug. DO NOT

USE SO CABLE - USE SINGLE LEAD WELDING CABLE

The following wire sizes are recommended for each unit.

Generator Size

Model AWG Insulation

25PTOC #4 Neoprene/THHN

If you require different inserts or contacts for local code,

WINCO has a variety of different inserts and contacts avail-

able. Contact the factory at 507-357-6831 for pricing.

Figure 1

SINGLE PHASE

4 WIRE CONNECTION

CONTACTS

All 4 contacts

must be used.