5OPM-106 REV B

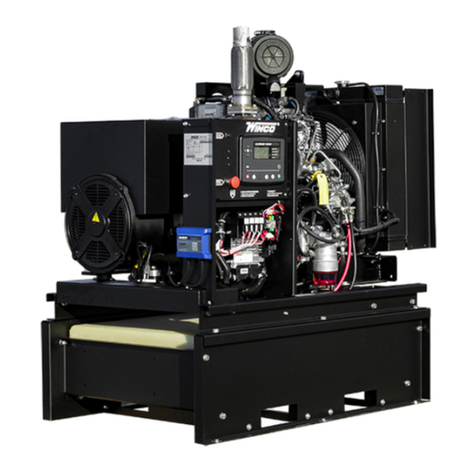

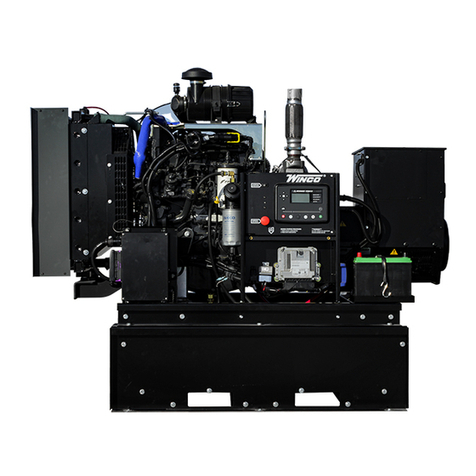

are equipped with generators manufactured by Cummins Generator

Technology. Each generator ‘end’ has its own data tag. A unique serial

number is on the data plate and the data label is affixed to the main

frame on the generator on the left side.

PREPARING THE UNIT

UNPACKING

1. As you receive your unit, it is critical to check it for any damage. If

any damage is noted, it is always easiest to refuse the shipment and

let WINCO take care of the freight claim. If you sign for the unit, the

transferoftheownershiprequiresthatyoulethefreightclaim

2. Before proceeding with the preparations of your new generator

for operation, take a couple of minutes to ensure the unit you have

receivedisthecorrectmodelandreviewthespecicationpagesinthis

manual to ensure that this unit meets your job requirements.

CAUTION: EQUIPMENT DAMAGE:

This unit is shipped with oil and a 50/50 mix of coolant. Be sure to

check all uid levels before operating. See engine manufacturer’s

instruction manual for recommended oil requirements before initial

starting.

Once generator set is on-site:

1. Carefully remove the crate.

2. After inspecting the engine-generator for external, physical damage,

locate and check the following items packed with the unit:

a. Installation and Operator’s Manual.

b. Engine manufacturer’s instruction manual.

c. Battery hold-down brackets & hardware.

d. Unit components or accessory items shipped loose for on-site

installation.

e. Optional accessories.

3. Remove main frame hold-down bolts.

4. Unit can now be lifted from shipping rails.

LIFTING THE GENERATOR SET

NOTICE: PERSONAL INJURY:

To prevent injury to persons or equipment, observe the following

guidelines when lifting the generator:

Duetothedifferentdesigns,congurations,options,weights,site

conditions,andavailablematerialhandlingequipment,speciclifting

instructions are not provided for each individual generator set model.

General guidelines provided are applicable to the entire generator

line. It is the responsibility of the installing party to follow the lifting

equipment’s operator’s manual to prevent injury to personnel and

damage to the generator. Smaller generator sets may not require use

of overhead lifting equipment and may be placed on the pad with basic

material handling equipment, i.e. a forklift.

CAUTION:

Do not attempt to lift the generator set by the means of the lifting eyes

on the engine or generator end. These lifting points are only for the use

during the manufacturing process and are designed for lifting of the

individual generator set components.

WARNING:

NEVER attempt to lift the fuel tank lled with fuel. Sloshing of the

fuel can cause a shift in the balance of the fuel tank, making for a

DANGEROUS, unbalanced lifting load. If the generator was shipped on

the fuel tank, use the lifting points located on the fuel tank to move the

entire generator set into place. DO NOT PLACE FUEL IN THE TANK

PRIOR TO LIFTING.

INSTALLATION

WARNING: PERSONAL INJURY:

Before proceeding with the installation, be sure the engine control is

in the “stop” position. Also, be sure the generator MLCB (main line

circuit breaker) in is the “off” position and the unit starting battery is

disconnected.

GENERAL INFORMATION

This engine-generator set is designed and built as an open power unit,

meaning no weather protection has been provided. This unit must be

installed inside of an enclosure that will provide proper protection from

the elements and ventilation.

Before beginning the installation process, recheck the voltage, phase,

and amperage rating of the generator set. Be certain it can handle the

intended load and are compatible with the intended loads. Plans for

installation should be prepared with proper attention to mechanical and

electrical engineering detail to assure a satisfactory system installation.

The installation must comply with all national, state, and local codes.

Theinformationinthismanualisofferedonlyasaguidetonalizing

your installation plans.

ENGINE GENERATOR SET MOUNTING

The unit’s main frame must be bolted solidly to a solid base. The en-

gine-generator is mounted on channels which are attached with special

shock mounts to the main frame. This allows the engine-generator free

movement without affecting the base or surrounding equipment.

WARNING: EQUIPMENT DAMAGE:

Never mount these engine-generator sets to a wooden base/structure.

Over time, the wood will deteriorate and the unit mountings will come

loose. These units must be mounted to a steel or concrete base.

The unit should be mounted to allow ample working room around it.

A general rule to follow is to allow 24 inches or more of clearance

for maintenance. Follow local codes for clearance from combustible

surfaces.