4

60706-259/A

SAFETY

IMPORTANT SAFETY INSTRUCTIONS

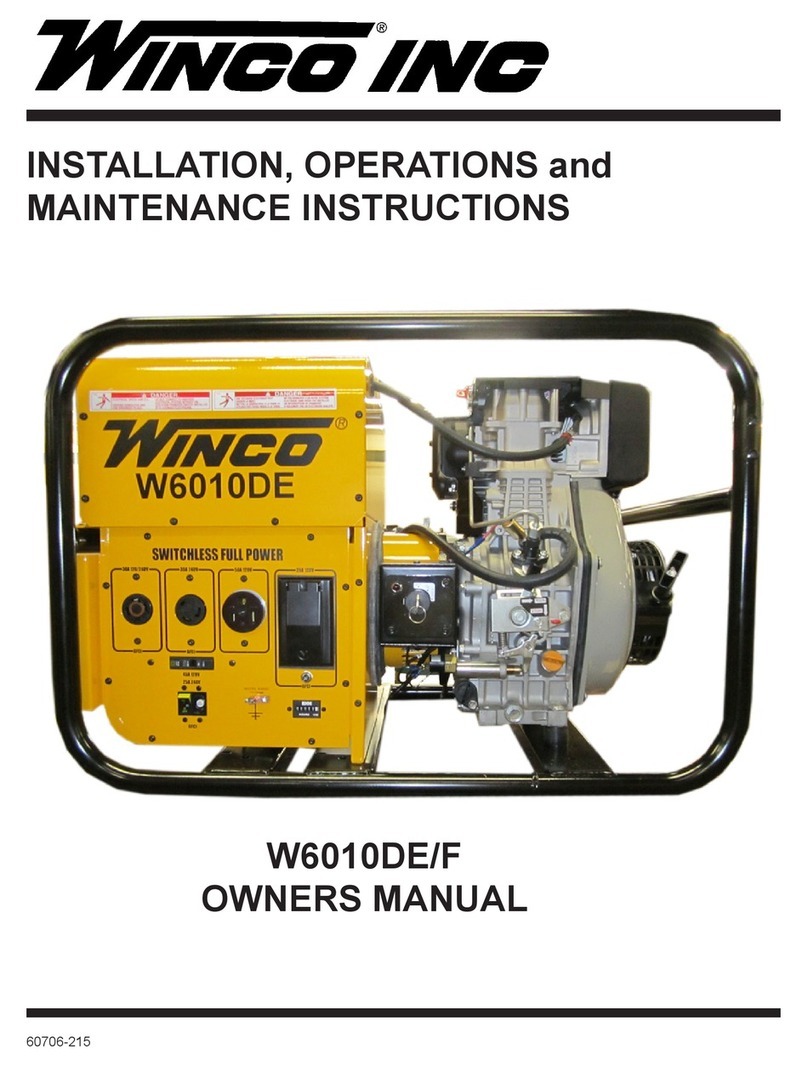

This engine generator set has been designed and

manufactured to allow safe, reliable performance. Poor

maintenance, improper or careless use can result in

potentially deadly hazards; from electrical shock, exhaust

gas asphyxiation, or fire. Please read all safety instructions

carefully before installation or use. Keep these instructions

handy for future reference. Take special note and follow all

warnings on the unit labels and in the manuals.

SAFETY DEFINITIONS

DANGER

Indicates an imminently hazardous situation

which, if not avoided, will result in death or

serious injury.

WARNING

Indicates a potentially hazardous situation

which, if not avoided, could result in death

or serious injury.

CAUTION

Indicates a potentially hazardous situation

which, if not avoided, may result in minor or

moderate injury. It may also be used to alert

against unsafe practices.

CALIFORNIA PROPOSITION 65

WARNING: This product contains crude oil,

gasoline, diesel fuel and other petroleum

products, Antifreeze to which can expose you

to chemicals including toluene and benzene,

Ethylene glycol (ingested) which are known to the

State of California to cause cancer, birth defects or other

reproductive harm and developmental issues.

For more information go to www.P65Warning.ca.gov.

DANGER: ELECTRICAL SHOCK

The output voltage present in this equipment can cause

fatal electric shock. This equipment must be operated by a

responsible person.

A. Do not allow anyone to operate the generator

without proper instruction.

B. Guard against electric shock.

C. Avoid contact with live terminals or receptacles.

D. Use extreme care if operating this unit in rain or

snow.

E. Use only three-pronged grounded receptacles

and extension cords.

F. Be sure the unit is properly grounded for your

application.

DANGER: DEADLY EXHAUST GAS

Exhaust fumes from any gasoline engine contain carbon

monoxide, an invisible, odorless and deadly gas that must

be mixed with fresh air.

A. Operate only in well ventilated areas.

B. Never operate indoors including attached

garages

C. Never operate the unit in such a way as to allow

exhaust gases to seep back into closed rooms

(i.e. through windows, walls, floors).

WARNING: FIRE HAZARD

Gasoline and other fuels present a hazard of possible

explosion and/or fire.

A. Do not refuel when the engine is running or hot.

B. Keep fuel containers out of reach of children.

C. Do not smoke or use open flame near the

generator set or fuel tank.

D. Keep a fire extinguisher nearby and know its

proper use. Fire extinguishers rated ABC by

NFPA are appropriate.

E. Store fuel only in an approved container, and

only in a well ventilated area.

F. Follow local codes for closeness to combustible

material.

CAUTION: PERSONAL INJURY

The muffler becomes very hot during operation and for a

period after the unit has been turned off. Do not touch the

muffler until it has completely cooled off.

CAUTION: NOISE HAZARD

Excessive noise is not only tiring, but continual exposure

can lead to loss of hearing.

A. Use hearing protection when working around

this equipment for long periods of time.

B. Keep your neighbors in mind when using this

equipment.

CAUTION

Keep the generator and surrounding area clean.

A. Remove all grease, ice, snow or materials that

create slippery conditions around the unit.

B. Remove any rags or other materials that could

create a potential fire hazard.

C. Carefully clean up any gas or oil spills before

starting the unit.

CAUTION

All service, including the installation or replacement of

service parts, should be performed only by a qualified

technician.

A. Use only factory approved repair parts.

B. Do not work on this equipment when fatigued.

C. Never remove the protective guards, covers, or

receptacle panels while the engine is running.

D. Use extreme caution when working on electrical

components. High output voltage from this

equipment can cause serious injury or death.

E. Always avoid hot mufflers, exhaust manifolds,

and engine parts. They can cause severe burns

instantly.

F. The use of the engine-generator set must comply

with all national, state, and local codes.