Global Power Technologies IMPORTANT SAFETY INSTRUCTIONS

05585 rev11 | Model 8550-SD Page 1 of 53

1IMPORTANT SAFETY INSTRUCTIONS

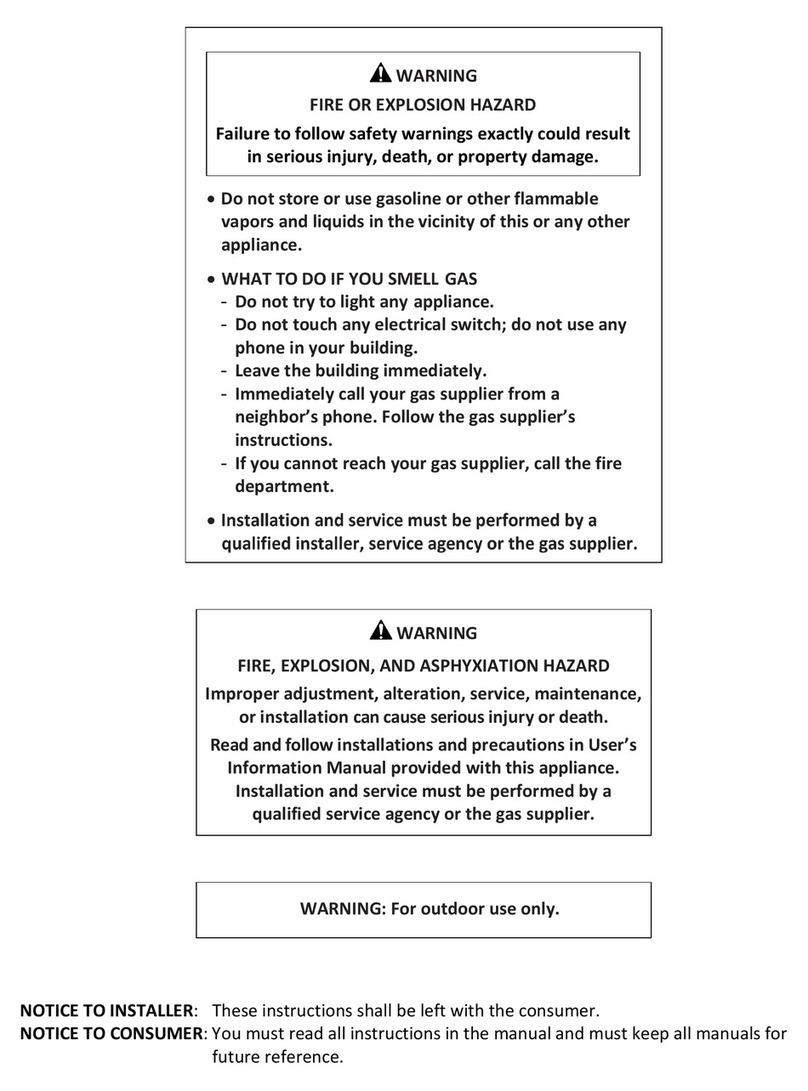

WARNING!

Read all application documentation, including manuals for equipped options,

before starting assembly, installation, or performing service check or maintenance

on the Thermoelectric Generator.

SAVE THESE INSTRUCTIONS – This manual contains important instructions for safe installation,

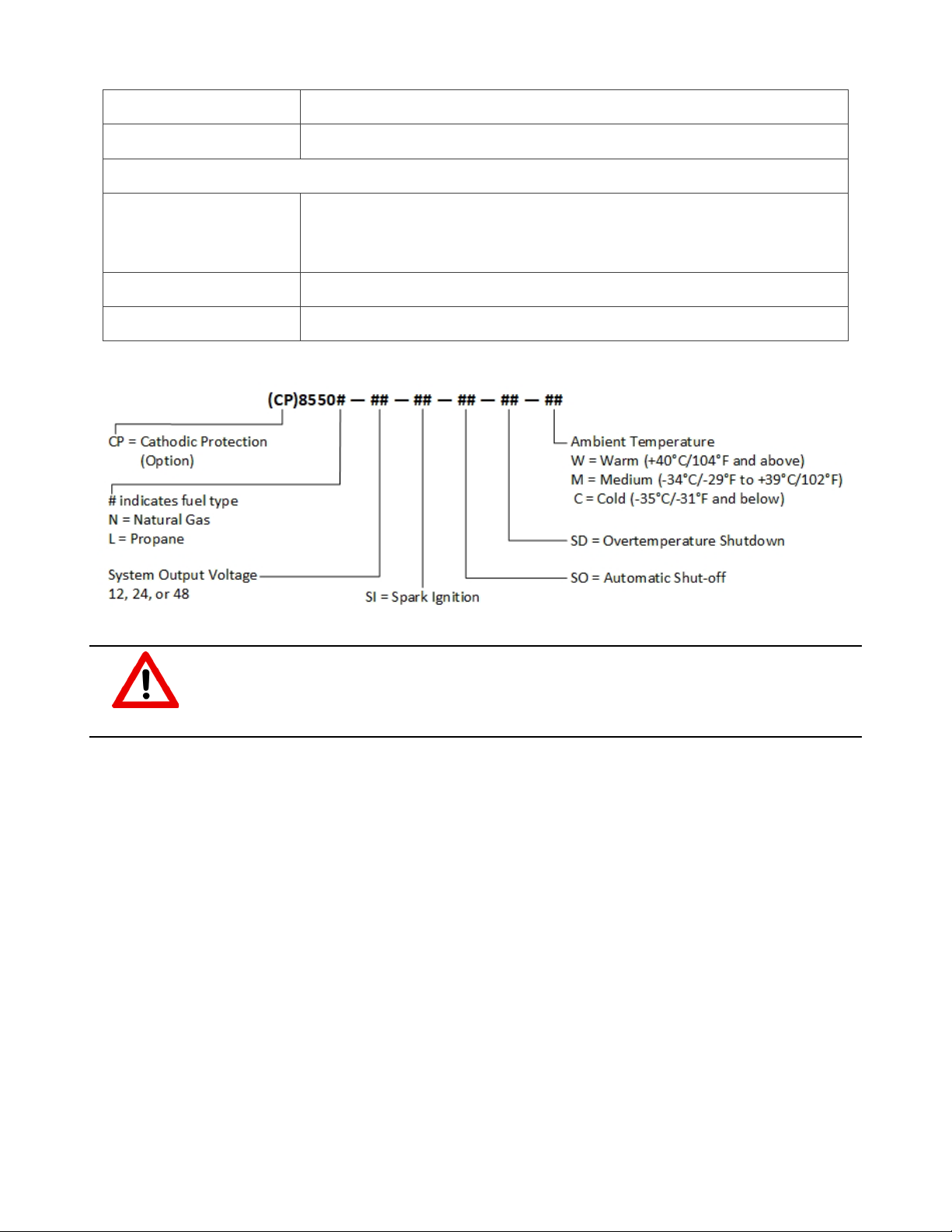

operation, and maintenance of the Global Power Technologies Model 8550-SD Thermoelectric

Generator with Overtemperature Shutdown.

Read the following safety warnings and pre-cautions before beginning assembly.

1. The installation must conform with local codes, or in the absence or local codes, with the CSA-

B149.1, Natural Gas and Propane Installation Code and CSA-B149.2, Propane Storage and

Handling Code.

3. Keep the Thermoelectric Generator area clear and free from combustible materials, gasoline, and

other flammable vapours and liquids. Maintain the minimum clearances specified in this manual.

4. Do not use this Thermoelectric Generator if any part has been under water. Immediately call a

qualified service technician to inspect the Thermoelectric Generator and to replace any part of

the control system and any gas control that has been under water.

5. The Model 8550-SD Thermoelectric Generator contains electrical- and gas-related safety devices

as identified throughout this manual. Tampering and rendering inoperative any of these safety

devices may result in personal injury or death and possible damage to the equipment and is not

permitted under any circumstances.

6. The Thermoelectric Generator is designed to combust gaseous fuels which will result in

combustion products including heat, carbon dioxide, and water vapour and may contain traces of

carbon monoxide, unburned hydrocarbons, and nitrous oxides. Emissions from combustion will

depend on generator set-up and operation as well as the composition of the gas feed. Ensure that

gas supplied meets Global Power Technologies’ gas specifications.

7. Fuel supplied to the Thermoelectric Generator must not contain liquids. Liquid hydrocarbons in

the fuel supply pose a risk of fire and may result in serious damage to the Thermoelectric

Generator and danger to the operator.

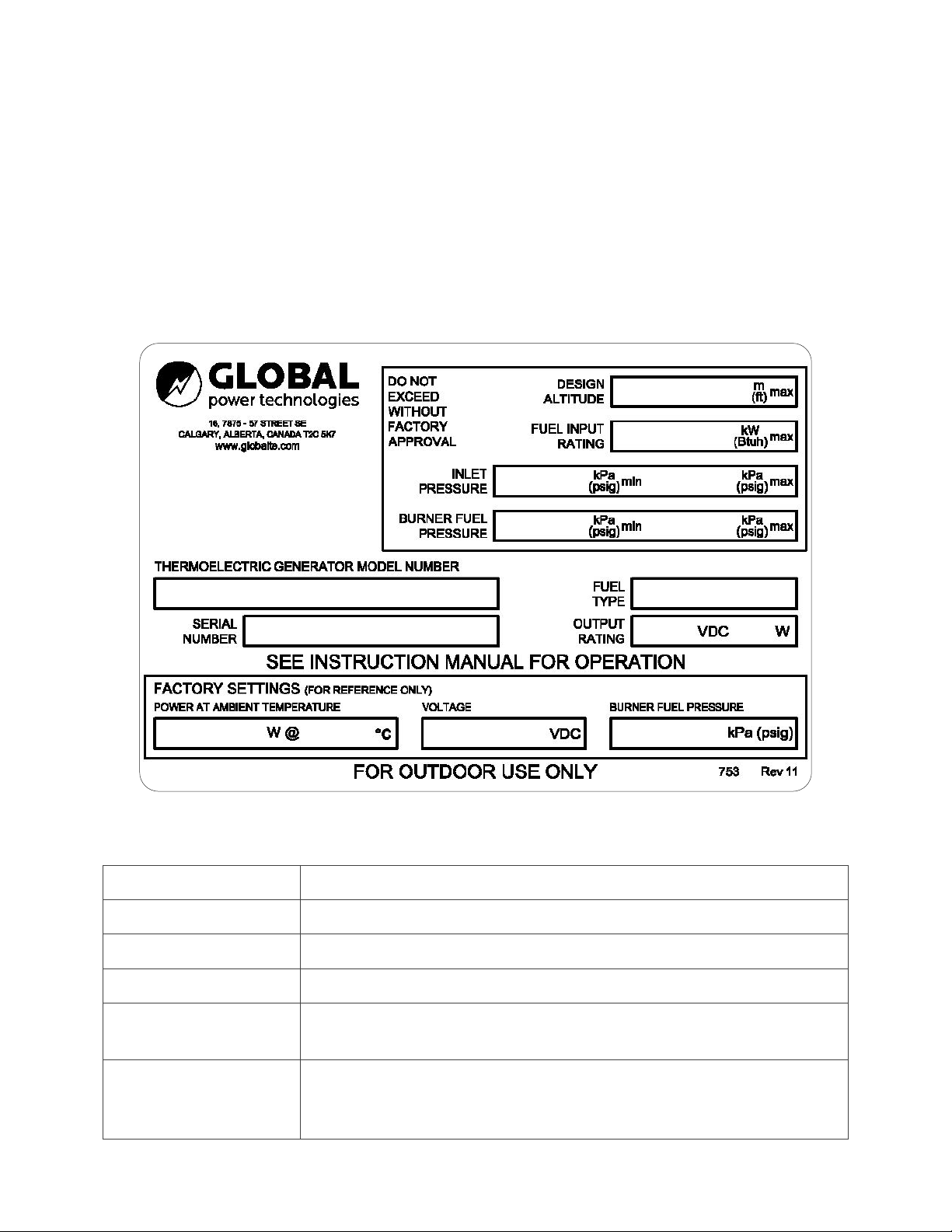

8. Do not exceed the fuel pressure stamped on the Thermoelectric Generator data plate without

factory approval. If fuel pressure exceeds reasonable levels, the power unit may be seriously and

permanently damaged.

9. The Thermoelectric Generator exhaust can be very hot. Do not touch any of the exhaust

components or bring exposed skin near hot exhaust gases.

10. If the Thermoelectric Generator has not been given enough time to cool, the spark electrode can

be dangerously hot.

11. The Thermoelectric Generator consists of some parts constructed from sheet metal. While every

effort is made to ensure that edges have been deburred when manufactured, sharp edges may

still exist. Exercise caution when handling. Wearing gloves is recommended.

12. When the Thermoelectric Generator is operating, surface temperatures of the unit can approach

temperatures close to 200°C. Avoid contact of skin and clothing with the surfaces of the

Thermoelectric Generator to avoid burns.

2. The Thermoelectric Generator, when installed, must be electrically grounded in accordance with

local codes, or in the absence of local codes, with the Canadian Electrical Code, CSA C22.1.