INSPECTION

OPERATION

Please carefullyunpack and inspectyour machine

for shipping damage. Eachunit is operatedand thor

-

oughlyinspectedbeforeshipment,andany damage is

the responsibilityof the delivering carrierwho should

be notifiedimmediately.

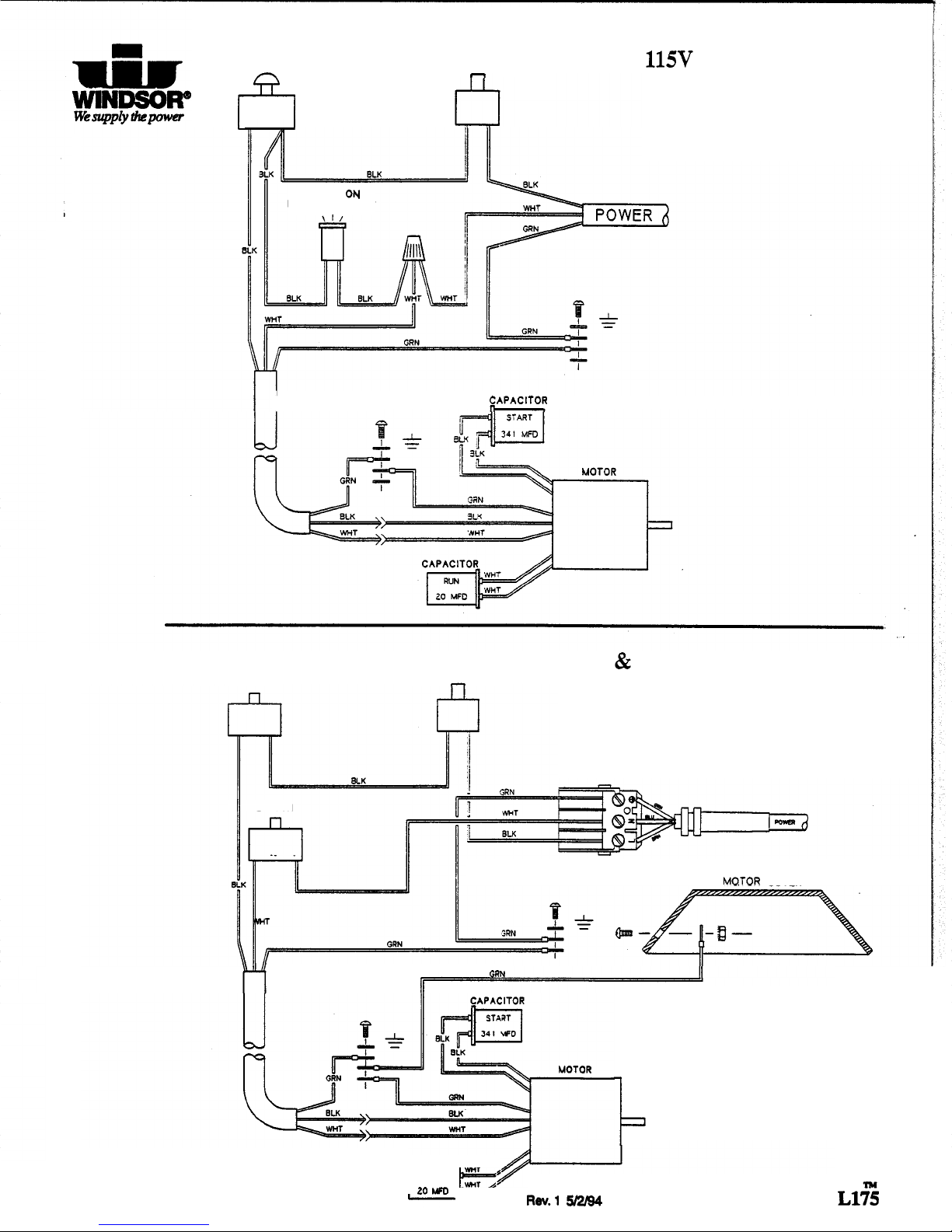

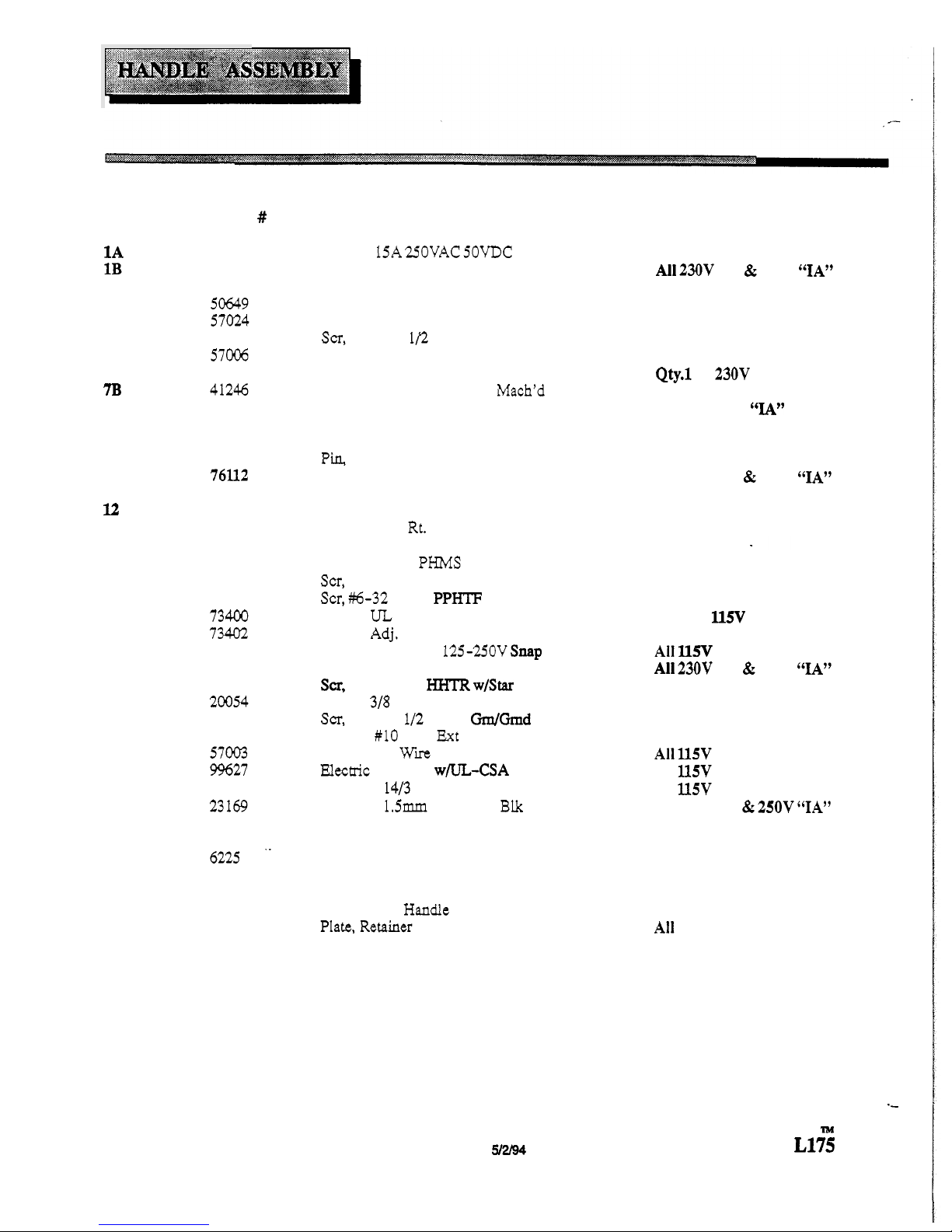

ELECTRICAL

Thisrotary polisheris designedto operateon astandard

15

amp,

115

volt,

60

hz,

AC

householdcurtent. Checkthatthe

voltageshown onthe serial numberplateissuitablefor the

supplyavailable.Voltagesbelow

105

voltsor above

125

volts

couldcausedamage to the motor.

NOTE: 230/250volt

50

hz

models

areavailable.

,

GROUNDING INSTRUCTIONS

Thisappliancemustbegrounded.

If

itshouldmalfunc

-

tionor breakdown, grounding providesa pathof least

resistancefor electriccurrenttoreducethe riskof elec

-

tric shock. This appliance isequippedwithacord hav

-

inganequipment

-

groundingconductorandgrounding

plug. Theplugmustbeinsertedintoanappropriateout

-

let that is properly installed and grounded in accor

-

dancewith all localcodes and ordinances.

WARN

1

NG

:

Improper connectionof the equipment

-

grounding

conductor can result in

a

risk of electric shock.

Checkwithaqualifiedelectricianor serviceperson

if

you are indoubtas

to

whether the outlet

is

prop

-

erly grounded.

Do

not modify the plug provided

withthe appliance

-

if

itwill notfit the outlet, have

a properoutlet installedby

a

qualifiedelectrician.

This applianceisfor useon anominal 120

-

voltcircuit,

andhasagroundedplugthat looksliketheplugin

“Fig.

A

below.

A

temporaryadaptorthatlooksliketheadap

-

tor

in

“Fig

.

C“

below

may

beusedtoconnectthis plug

to

a

2

-

pole receptacleas shown in“Fig.

B

below,

if

a

properly groundedoutlet is not available. The tempo

-

rary adaptor should be used only until a properly

groundedoutlet (Fig.

A)

canbe installedby a qualified

electrician. Thegreencoloredrigidear, lug,

or

the like

extendingfromtheadaptormustbeconnectedtoaper

-

manentgroundsuchas aproperlygroundedoutletbox

cover. Wheneverthe adaptor

is

used, it must be held

inplace by a metalscrew.

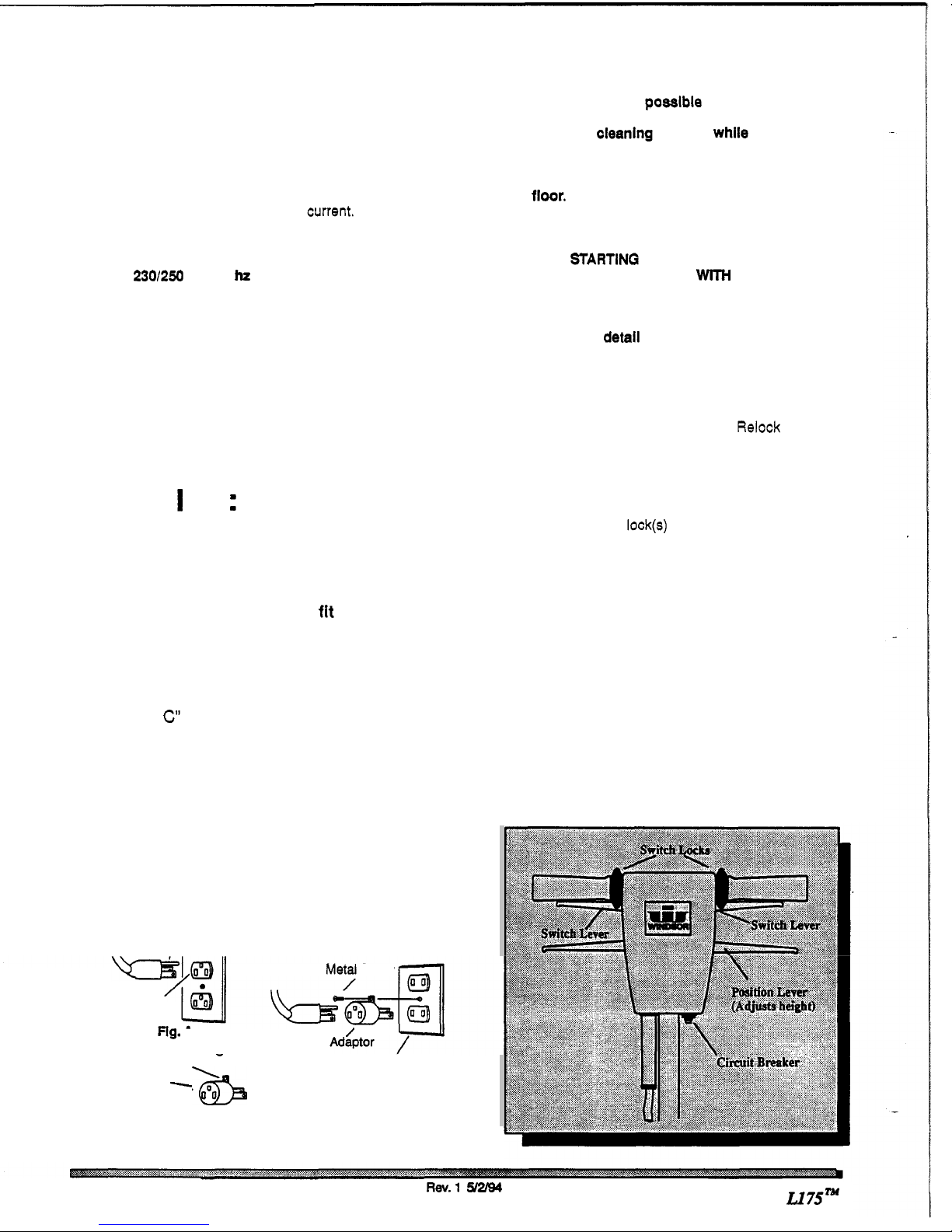

PROPER GROUNDING CONNECTION

CONNECTION USING

AN

ADAPTOR

GROUNDING

GroundingPin

\\

I

-

Metal

Screw

Grounded

Outlet

Rg.

A

/

Tab

For Groundina

-

Screw GroundedOutlet

Box

ADAPTOR

-

flg.

B

NOTE: Adaptors

are

notallowed InCanada.

‘6

Fig.

C

CAUTION: For indoor

Use

Only.

To

prevent possibledamage to thefloor

when using the Brushoptlon, usewater or other

approvedcleanlng solutionwhile operating.

When using the padoptloln, always keep

the machine movingwhen In contactwith the

floor.

WARNING:

HIGHSTARTINQ

TORQUE.

HOLD MACHINE FIRMLY

WITH

BOTH

HANDS.

1

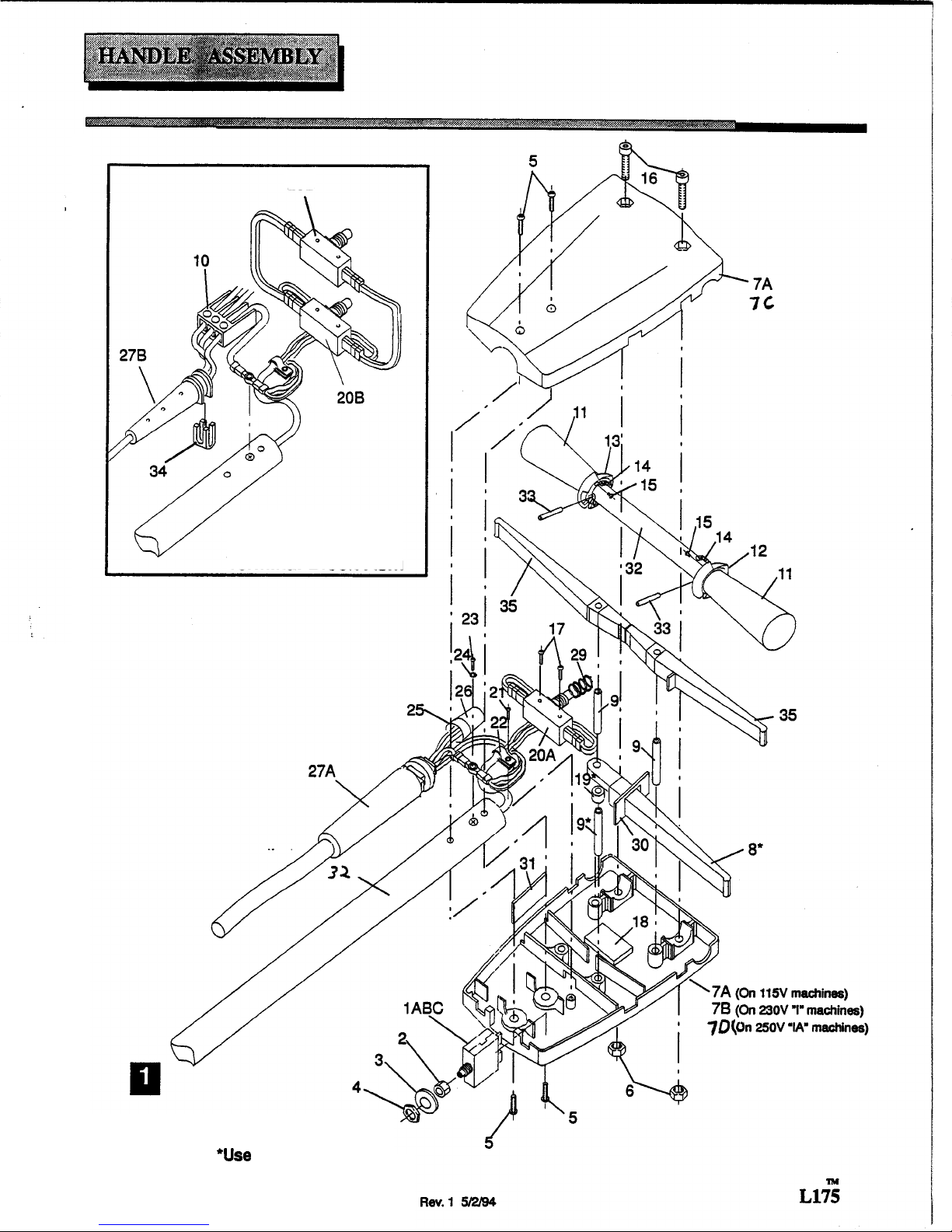

.)

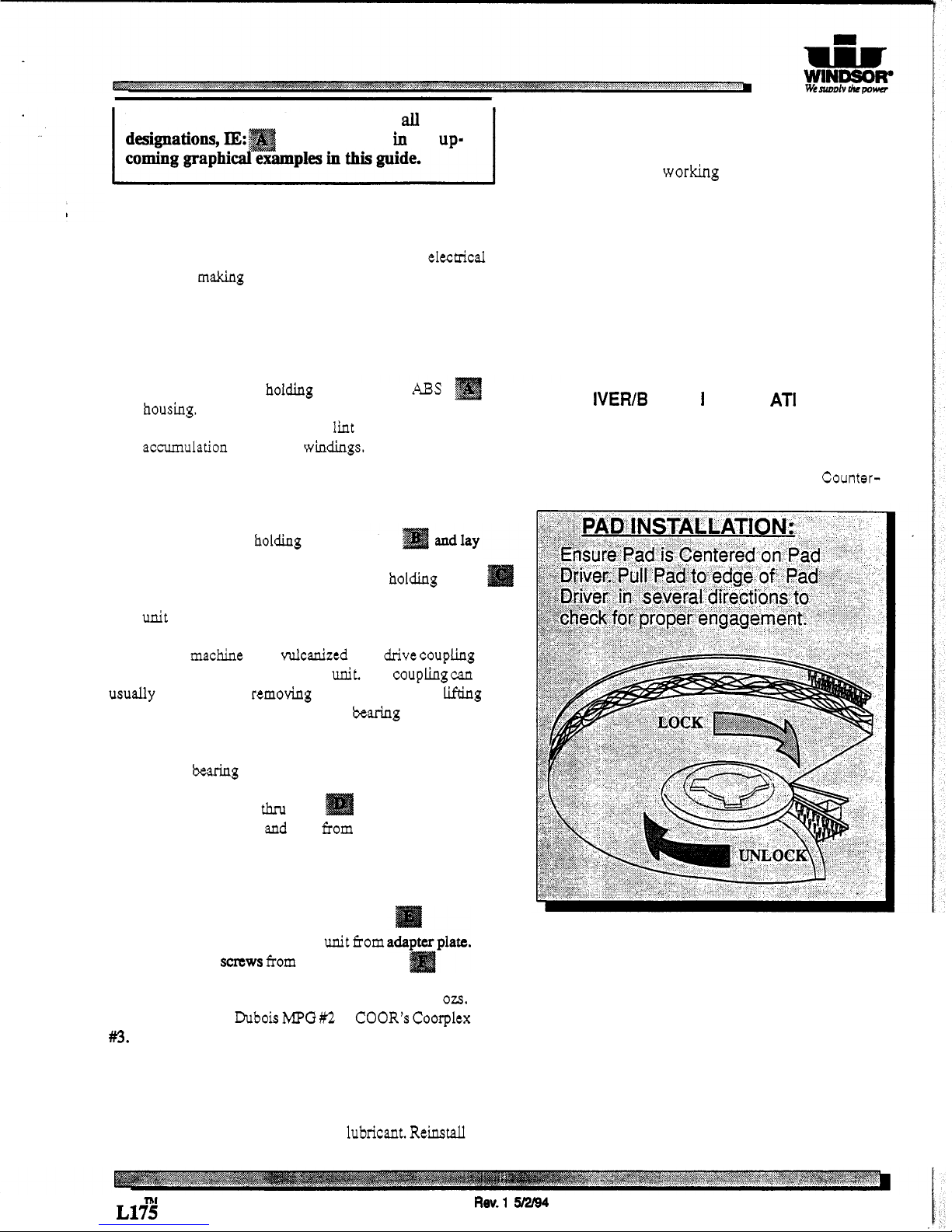

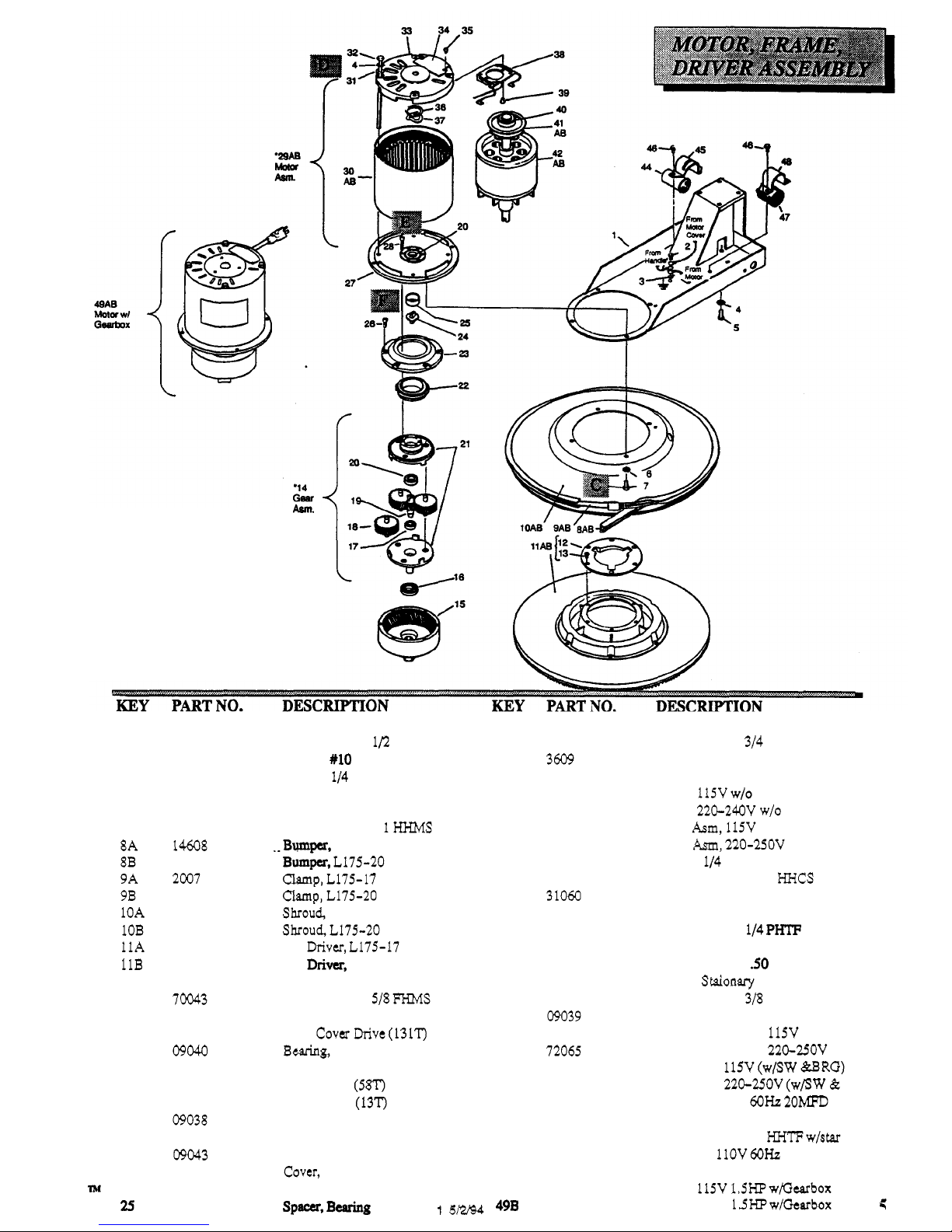

Ensurethatthepaddriver

or

brushisinstalledcorrect

-

ly and ingood shape. Installor change pad

if

necessary

(See Page 3

for

detall

of

Installation).

2.)

Plugthe machineintoawall outlet

as

describedinthe

grounding instructions.

3.)

Lowerthehandle

by

unlockingtheadjustmenthandle

and movingthe handle into position. Relock the handle

when itis ina comfortableposition.

4.)

Check to be sure the pad driver or brush is installed

beforestarting.

5.)

Withthe switch lock@)rotatedforward, squeeze

one

of theswitchlevers,turningthemachineon. (Theselevers

can beoperatedindependently

of

each other)

6.)

To

stop the machine, release the switch lever

and

switchlock.

NOTE

The machineisequippedwitha circuitbreaker

to

protectthe motor inthe event

an

overload condition

occurs. The circuitbreaker islocated

at

thebottom

of

the

switch housing. Push the reset buttonto restart the ma

-

chine.

If

thebreakertripsagain, correctthecause

of

over

-

loadingbeforeproceeding.

7.)

Do

notletmachinerestonpad. Whenfinishedwiththe

machinefor the day returnhandletothe storage position.

Besureto leavemachineina

safe

placewherethere isno

risk

of

beingtippedover.

CONTROLS

Page

2

R0v.l

y2/94

L175”