1-800-777-8466

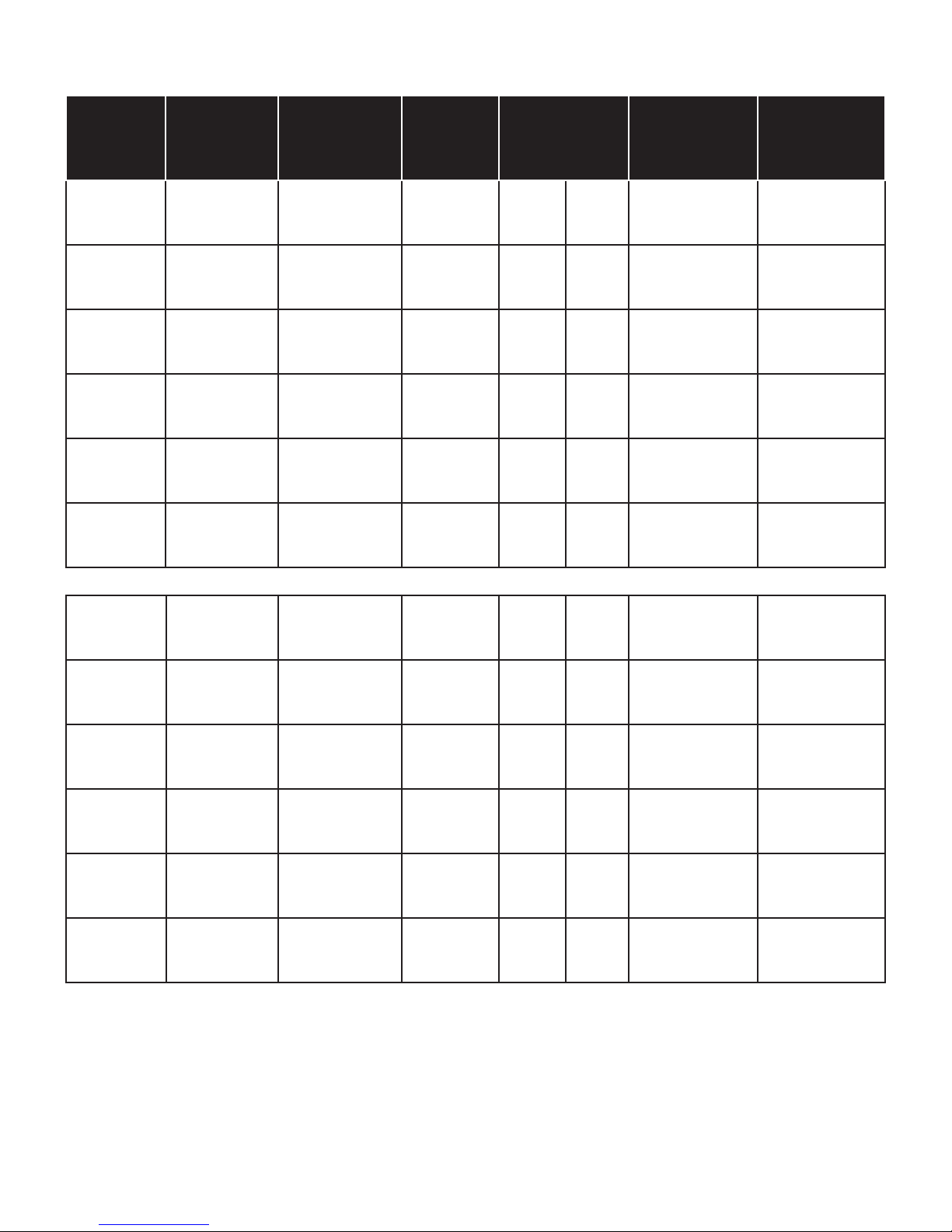

TABLE OF CONTENTS

Important Safety Information..........................................................................................................................

Feature Descriptions.............................................................................................................................................

HTD and HTD-TE Units................................................................................................................

CD and CD-TE Units......................................................................................................................

HZD Units........................................................................................................................................

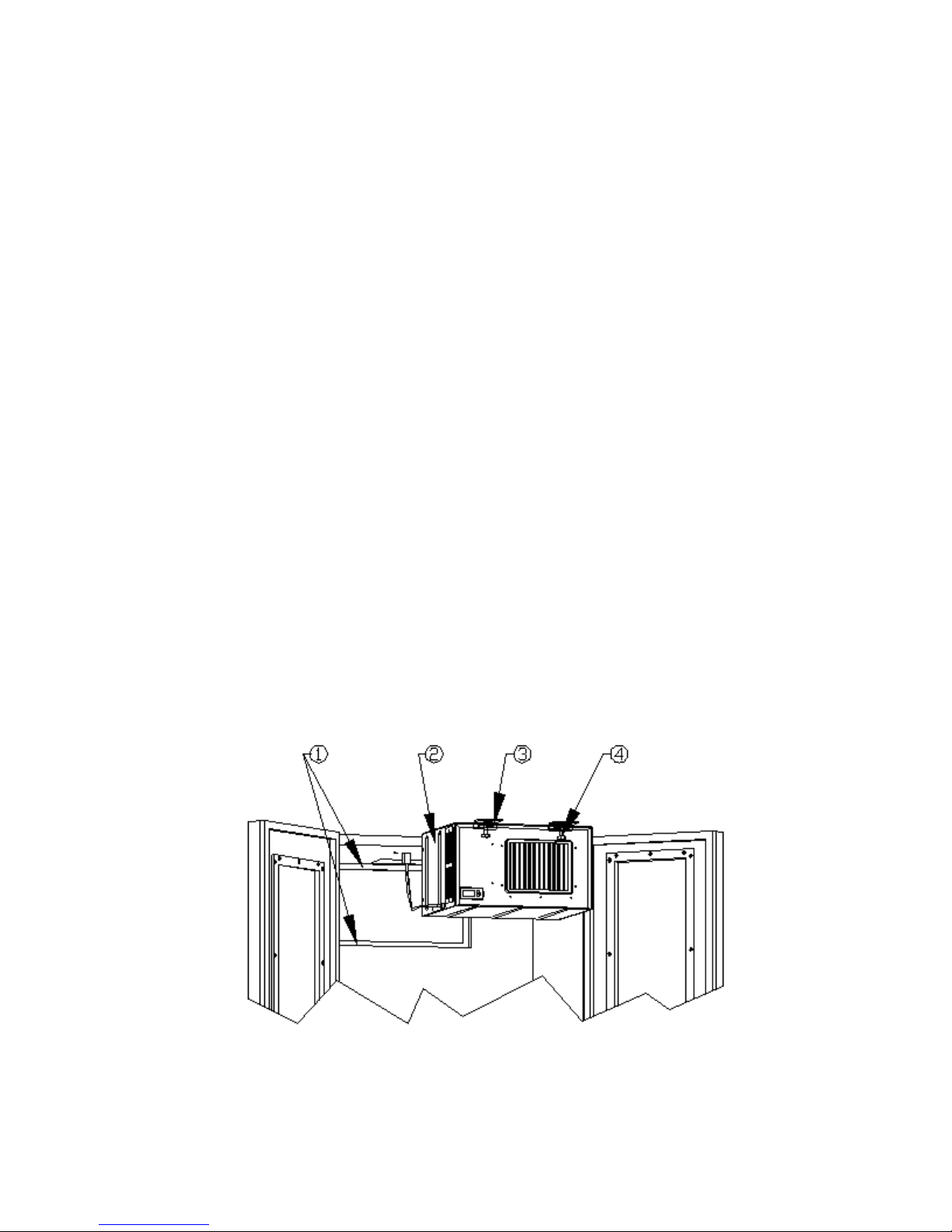

Installation Instructions.......................................................................................................................................

HTD and HTD-TE Units................................................................................................................

CD and CD-TE Units......................................................................................................................

HZD Units........................................................................................................................................

Temperature and Humidity Control...............................................................................................................

Use of the Digital Controller................................................................................................................

Cleaning and Care Guide.....................................................................................................................................

Troubleshooting Guide........................................................................................................................................

Electrical Wiring.......................................................................................................................................................

HTD and HTD-TE Units................................................................................................................

CD and CD-TE Units......................................................................................................................

HZD Units........................................................................................................................................

Appendix.....................................................................................................................................................................

Warranty......................................................................................................................................................................

Wine-Mate Cooling Systems..............................................................................................................................

3

4

5

6

8

10

11

13

14

19

20

22

23

27

27

27

28

29

30

31

2