Phone 1.800.234.5286 | 1.502.495.5400 | 1.502.495.5458 • Mail 2345 Carton Drive | Louisville, KY 40299 USA

3

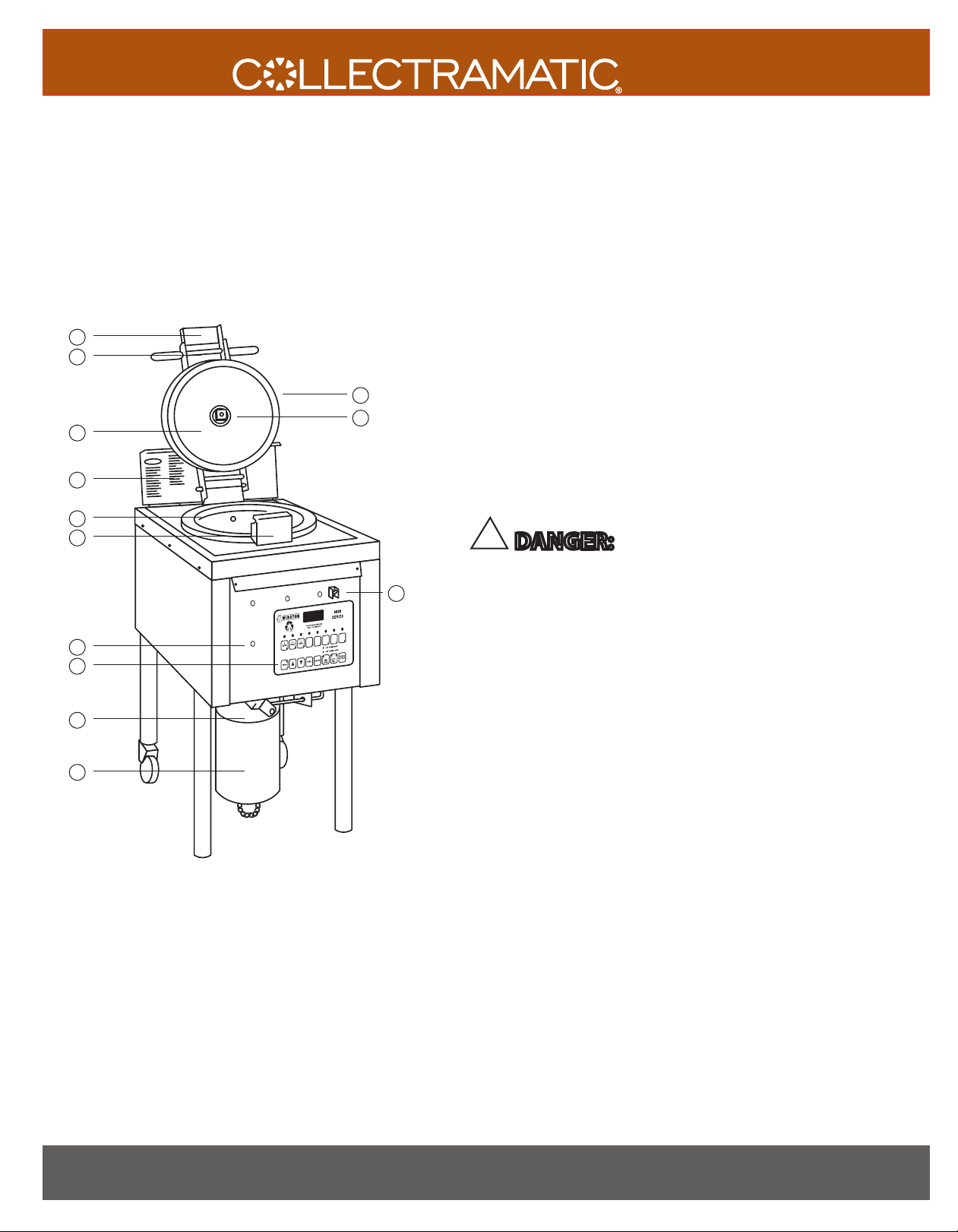

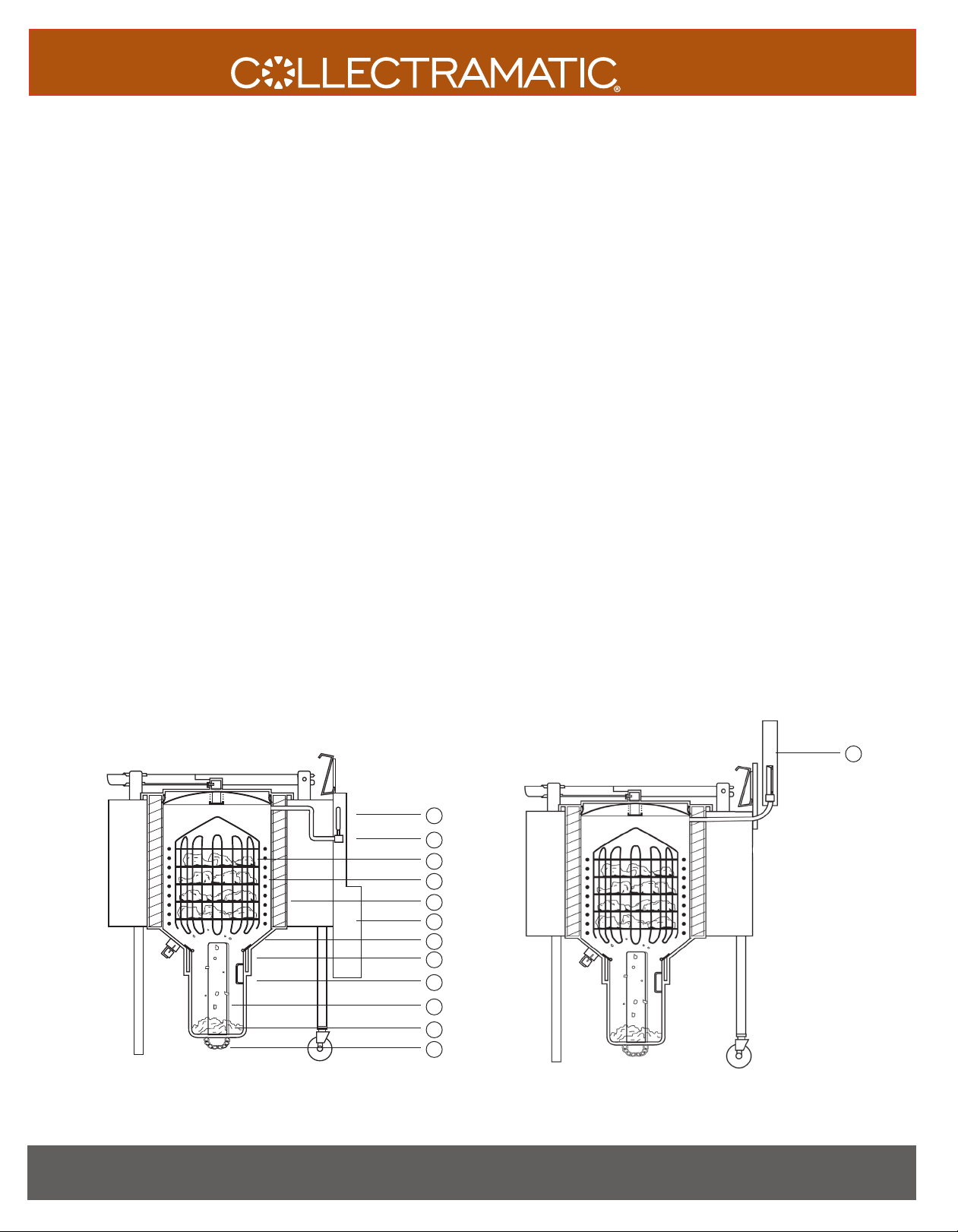

FRYERS

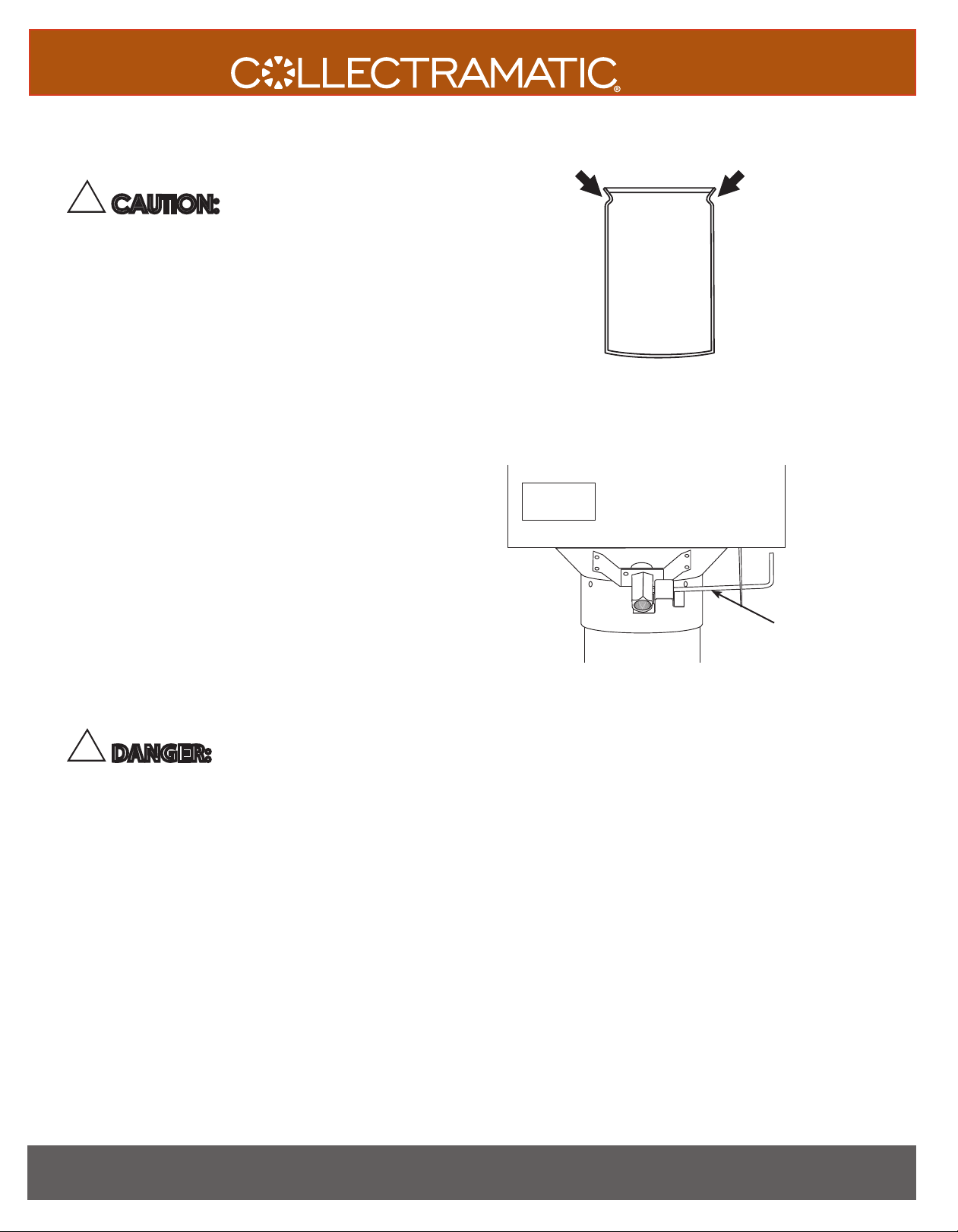

12. HOT LIQUIDS UNDER PRESSURE

To safely close lid:

A. Use both hands on handlebar to lower lid.

B. Pull handlebar completely into lid lock block so

that lid lock pops up (‘clank’ sound) into its

straight, locked position.

To safely open lid:

A. Wait until cook cycle is nished (timer at 00:00

and buzzer sounds).

B. Do not touch handlebar to open lid until

pressing down on lid lock causes the lid to lower.

C. Then with the lid in the lowered position, use

one hand to move handlebar to open.

13. DO NOT open drain valve until fryer power is OFF and lid is

open. Use safety gloves and place an appropriate container or

lter in position under drain valve before opening valve.

14. DO NOT install or attach any piping or tubing to drain valve

other than Winston drain valve extension.

15. DO NOT handle fryer basket without using safety gloves and

basket hook or lift assist tool.

16. DO NOT stir cooking oil in collector after the rst round

of cooking each day. Cooking oil may come up and out

of cookpot.

17. DO NOT clean or move fryer until you have disconnected fryer

from power, completely removed lid, drained cooking oil, and

removed collector. Never use “boil-out” method or water for

cleaning fryer cookpot.

18. DO NOT splash water or use hose on outside of fryer. Use only

damp towel to clean fryer surfaces outside of cookpot.

19. DO NOT use any liquids other than cooking oils in fryer

cookpot.

20. PURCHASE only Winston authorized replacement parts, which

will provide the most current danger warnings.

21. ALWAYS turn power switch to OFF anytime fryer

is not in use.

22. DO NOT use vent ball with ball-end deadweight.

23. INSTALLATION of this fryer may require the use of a licensed

electrician. Check local codes.

____________________________________________

!CAUTION:

Prior to using equipment for the rst time, perform the daily

care procedure listed on pages 15-17.

____________________________________________

RECEIVING YOUR EQUIPMENT

Thank you for your recent order. For your convenience, we have

summarized your responsibilities for receiving a shipment and

suggest procedures to follow if there is freight damage. Once

an order has left the factory all inspection responsibilities for the

shipment passes on to you.

If Merchandise Is Delivered in Damaged

Condition, You Must:

1. Have the driver note the damage and sign all copies of the

freight bill.

2. Examine for concealed damaged as soon as possible.

3. Notify carrier of the freight claim immediately

(You have a 24-hour window).

4. Retain damaged merchandise and all original packaging until

inspected by carrier.

Steps to Take at Time of Delivery to Protect

Against Loss or Damage

1. Verify count. Make sure you receive as many cartons as

are listed on the delivery receipt. Note any shortage on

carrier’s delivery receipt and have the driver note the

shortage on your copy.

2. Carefully examine each carton for damage. If damage is visible,

note this fact on the delivery receipt and have the driver clearly

note the same on your copy. If the carton appears to have

internal damage, insist that the package be opened. You and

the driver should make joint inspection of the contents. Any

concealed damage discovered should be noted on the receipt

and on your copy.

3. Immediately after delivery, open all cartons and inspect for

concealed damage.

Steps to Take When Visible or Concealed

Damage Is Discovered

1. Retain damaged items. The damaged items, shipping cartons,

and all inner packing materials must be held in the receiving

area until a carrier representative inspects them or waives the

opportunity to inspect.

2. Call carrier to report damage and request inspection. The call

should be placed immediately upon discovery of the damage.

Claims will be denied if not reported within 24/48 hours.

3. Conrm call in writing. For your own protection, conrm your

telephone claim in writing using certied, return receipt

requested mail.

Steps to Take When Carrier Makes Inspection

of Damaged Items

1. Have damaged items in receiving area. The damaged

items should have not been moved from the receiving

area. Allow the carrier inspector to inspect cartons, inner

packing materials, and freight bill. Show your copy of the

delivery receipt.

2. Carefully Read The Inspection Report Before Signing - If you do

not agree with the report, do not sign it.