- 7 -

Chapter 2 Terminal connection

2.1 The main circuit terminals are described below:

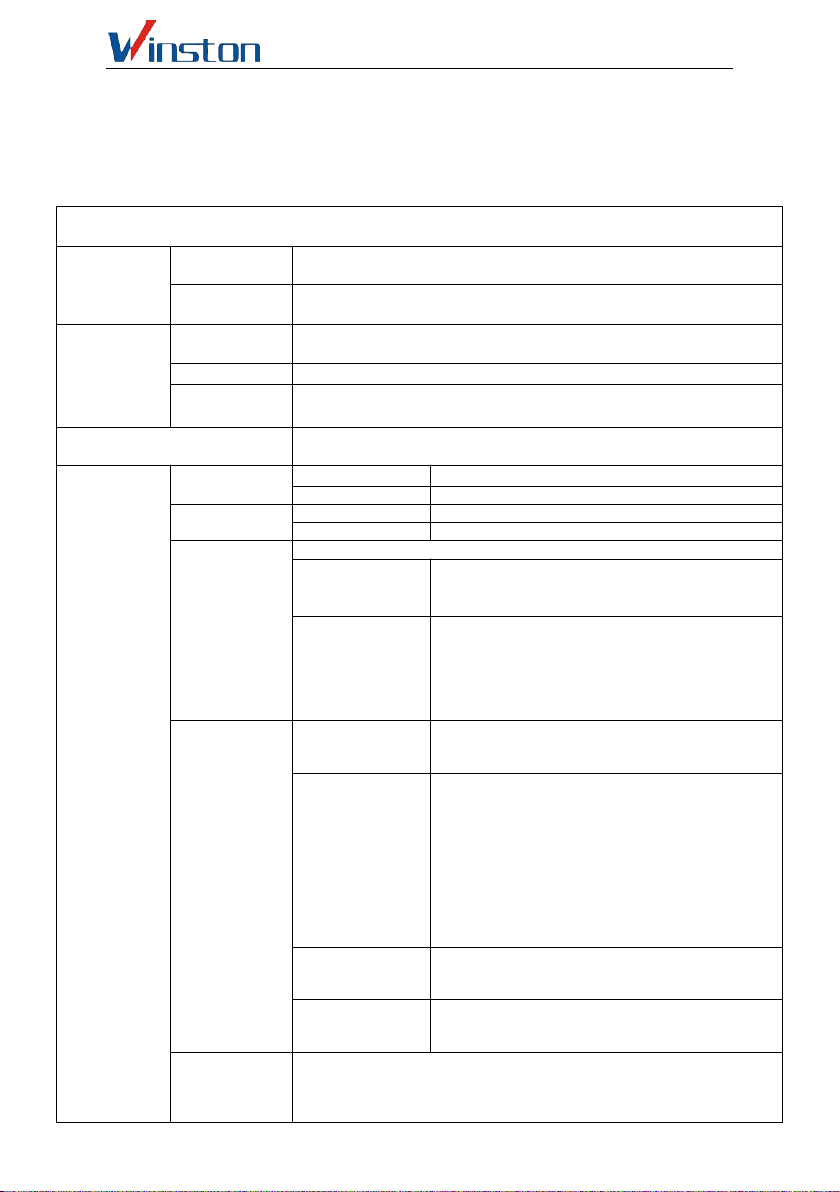

Table 4.1 Main circuit terminal function description

Terminal name function declaration

R S T Three-phase power input terminal

U V W Three-phase AC motor terminals

P+ P- External brake unit reserved terminal

P+ PB External brake resistance reserved terminals (30 kW

and below)

P+ P1 External DC reactor reservation terminal

G/PE Earth terminal

2.2 Terminal of control loop

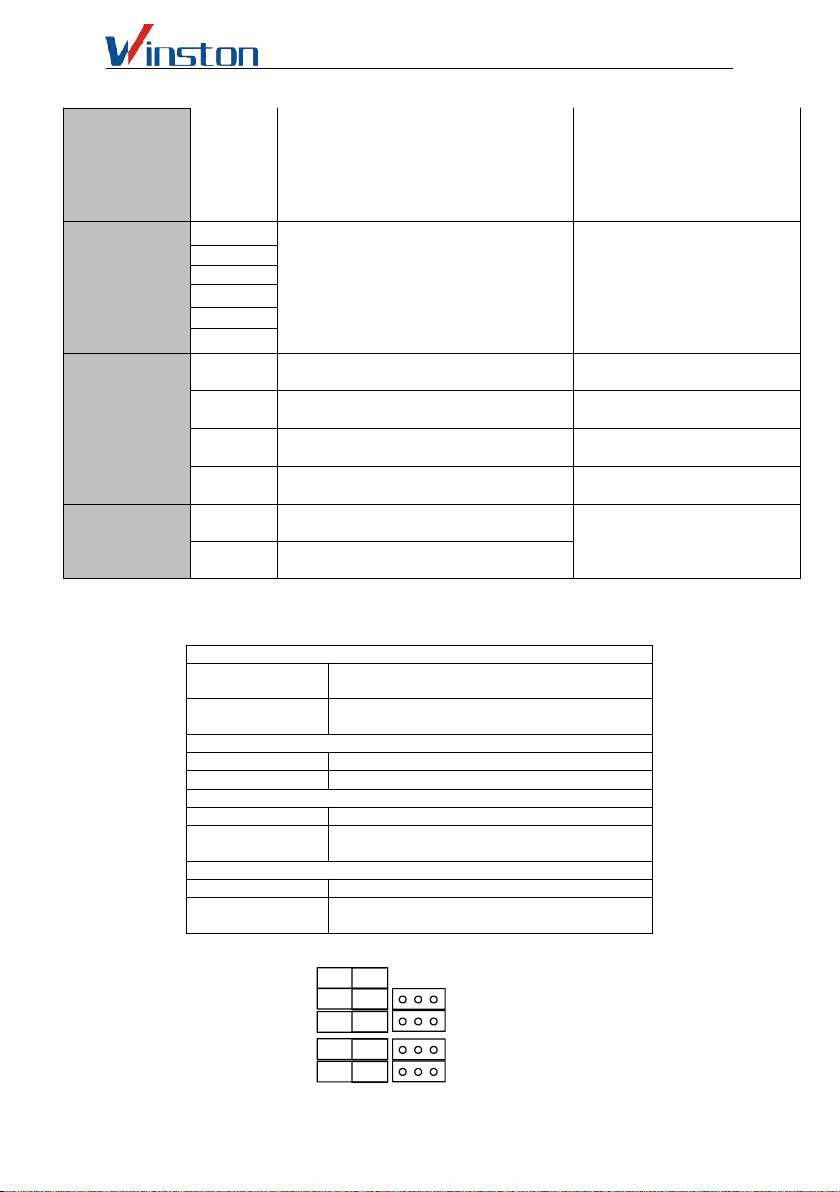

2.1 Distribution of control terminal of control panel

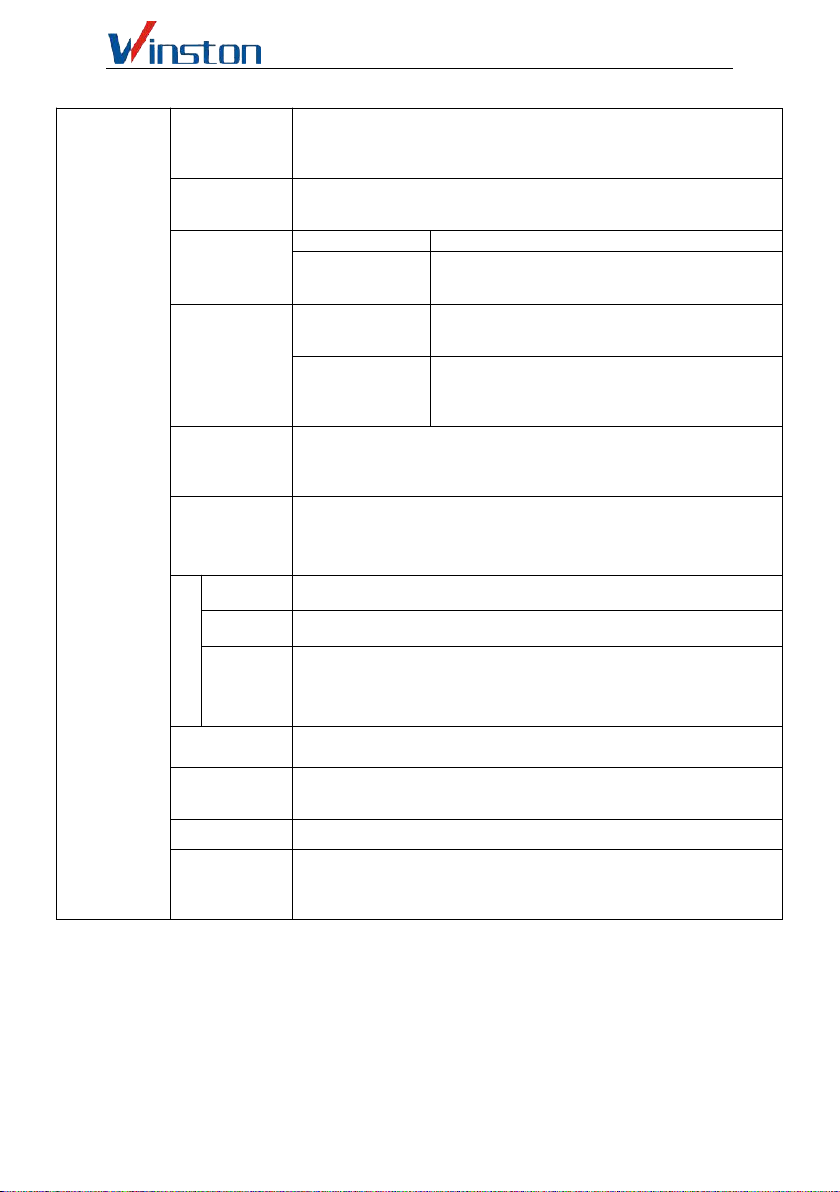

2.1 Function Description of Control Circuit Terminal

Category Terminal

label Function Description Specifications

Multifunctional

digital input

terminal DI

DI1 the short-time connection between DI

(DI1, DI2, DI3, DI4, DI5, DI6, DI7) is

effective, and its function is set by

parameter F07.00~COMF07.06,

respectively ,(common end: COM). INPUT,0-24 V level signal,

low level effective 5 mA.

DI2

DI3

DI4

DI5

DI6

DI7

DI7 can be used as a common

multi-function terminal, but also

programmable as a high-speed pulse input

port, see F07.06 function description.

Multifunctional

Digital Output

Terminal DO

DO1

DO (DO1, DO2) is a multifunctional

collector with open circuit output of up to 62

kinds. For details, see F07.18、F07.19

description of terminal function。

Opto coupler isolation, open

collector output, output voltage

range :0 V-24V

Output current range:

0mA-50mA

DO2

AO of analog

input AI output

terminals

AI1

AI1 receive analog voltage / current input,

voltage, current selected by jumper JP3,

factory default input voltage, if you want to

input is current, just adjust jumper cap to

Cin position; AI2 only receive voltage input.

Range setting see function code

F06.01~F06.10 description. (Reference:

GND)

INPUT, input voltage

range :0~10 V (input

impedance :100 KΩ), input

current range :0~20 input

impedance :500Ω).

AI2

AO1

AO1 provide the output of analog

voltage/current quantity, can represent 14

kinds of physical quantity, output voltage,

OUTPUT,0~10 V DC voltage.

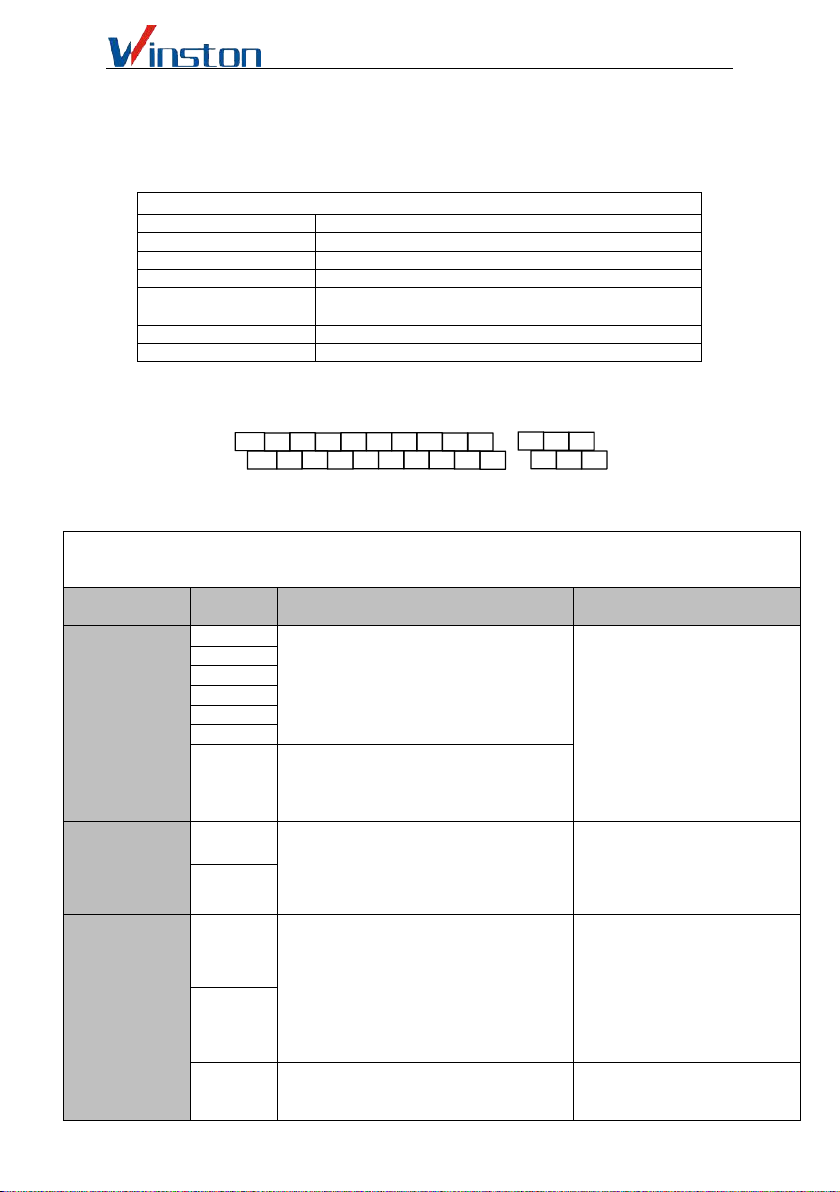

The output voltage of the AO1、

TB1

TA1 TC1

AI1 AI2 GND AO2 DI7 DO1

DI1 DI3 DI5 24V

10V GND AO1 485+ DI6 COM

485- DI2 DI4 DO2 TB2

TA2 TC2