Digital Technology & New Innovation !!!

Instruction Manual

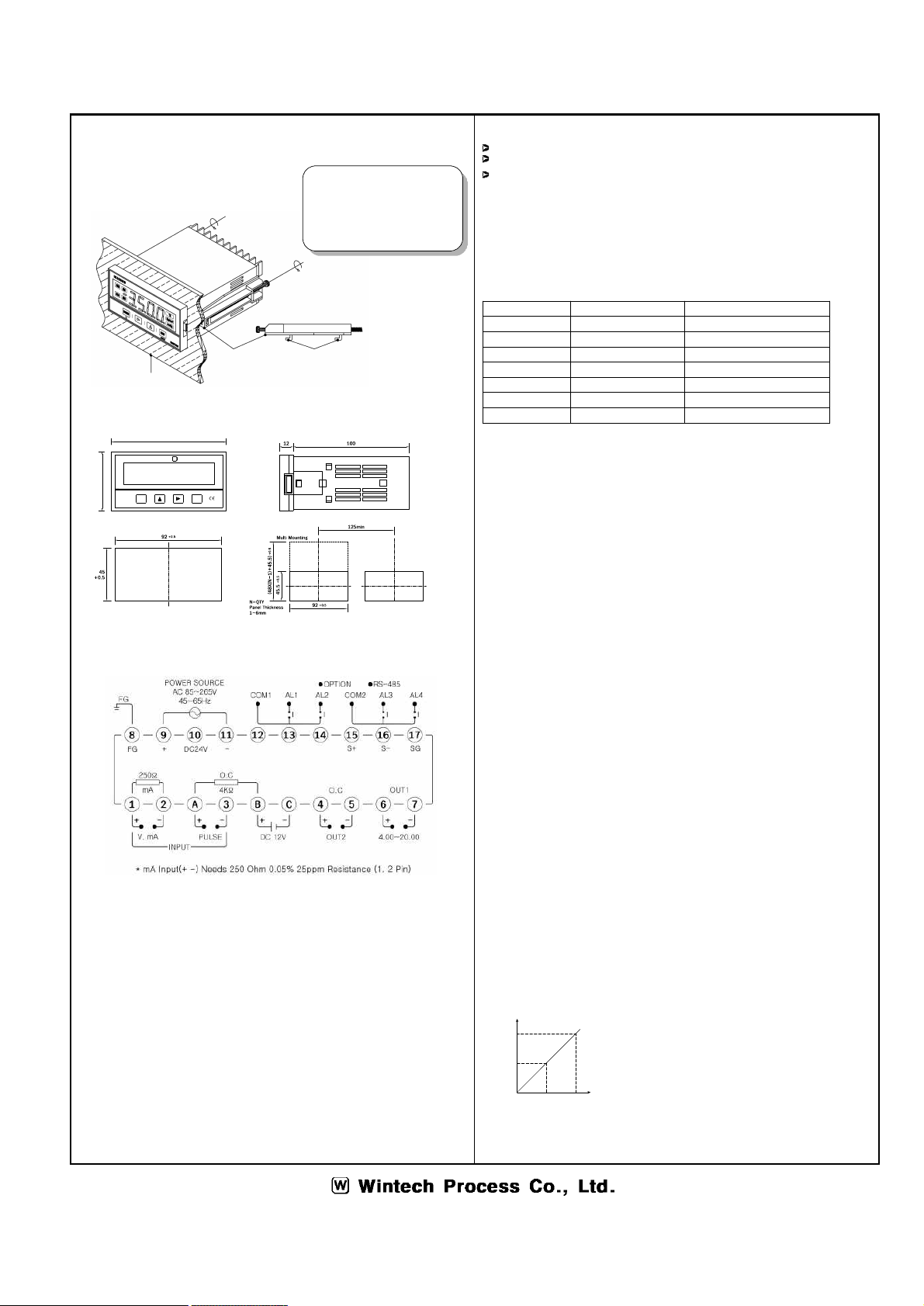

WP-3000 Series

Digital Indicators

Contents

WARNING / CAUTION / NOTE 1P

1. Checking the

Accessories 1P

2

. Part Name 1,2P

3. Installation

2P

4.

Terminal Diagram 2P

5.

Feature 2P

6.

General Specification 2P

7

. Major Functions 3P

8

. Operation and Setting Mode 3,4P

※ Be sure to observe following warning / cautions and

those provided in the text. In order to secure safety in

handing the instrument.

WARNING

- General

‣ In order to prevent electric shock, be sure to

disconnected this instrument from the main power

source when wiring.

- Protective Grounding

‣ In order to prevent electric shock ; be sure to

provided protective grounding prior to turning on this

instrument. Do not cut a protective

grounding conductor disconnected protective grounding.

- Power Source

‣ Make sure that the supply voltage for this

instrument conforms to the voltage source.

‣ Attach protective cover prior to turning on this instrument.

- Fuse

‣ In order to prevent a fire, use only our specified fuse.

‣ Don't short-circuit a fuse.

- Working Environment

‣ Do not operate this instrument in the environment where it

is exposed to a combustible, explosive, corrosive gas or

water, steam.

- Input and Output wiring

‣ Provide input and output wiring after turning off the power.

CAUTION

- Inside of instrument

‣ Do not disassemble the inside of the instrument.

‣ Prevent inflow of dust, water, oil and wiring dregs in to the

instrument.

- Input and Output wiring

‣ Do not use empty terminals for other purposes such

as relaying, etc.

‣ Wire correctly after checking the polarity and purpose of the

terminal.

‣ When wiring the instrument, separate from high voltage

cables, power lines, and motor lines to prevent

inductive noise.

- Transportation

‣ When transporting this instrument or the equipment with this

instrument incorporated in it, take measures to prevent

opening the door and falling out the inner module.

NOTE

- Instruction manual

‣ Deliver this instruction manual to an end user.

3456

MODE

AU TO

EXIT

WP3000

AL3 °C

mmHg

bar

AL1

AL4 AL2

1

7

2

WWin t e ch P ro c e s s C o.

‣ Prior to handing the instrument be sure to read this manual.

‣ If you have any question on this manual or fine any errors

omissions in this manual, contact our sales representative

‣ After reading this manual, keep it carefully by the

instrument.

‣ When the manual, is lost or stained, contact our sales

representative.

‣ It is prohibited to copy or reproduce this manual without

our permission.

- Checking the accessories

‣ Upon delivery instrument, unpack and check its accessories

and appearance. if there are missing accessories or

damage on the appearance contact our dealer where you

purchased the instrument or our sales representative.

- Installation

‣ When installing this instrument, put on a protective gear

such as safety shoes, helmet, etc. for your safety.

- Maintenance

‣ Only our serviceman or persons authorized by

Wintech Process Co. are allowed to remove and take the

inner module, the main unit and printed circuit boards apart.

- Disposal

‣ Disposed the used products in a correct way.

‣ Do not incinerate plastics of m

aintenance parts and

replacement parts. A harmful gas mat be produced.

‣ To dis

posed of this instrument, consign to the special

agent as an industrial waste.

- Cleaning

‣ Use dry cloth to clean the surface of this instrument

‣ Do not use any organic solvent.

‣ Cleaning the instrument after turning off the power.

- Revisions

‣ This instruction manual is subject to change without prior

notice.

- Evasion of responsibility guarantee

‣ Be sure to observe the caution in operating, maintaining,

and repairing this instrument. We will not be responsible

for or

guarantee the damage resulting from

negligence of them.

1. Checking the

Accessories

When you received, please check the Insufficient

accessories and defective products shape.

If the lack of parts, please contact the company.

2. Part Name

① Measured value display

② Alarm condition display

③ Memorize the setting data and change the operation menu.

④ Into the data setting mode and collect the changed

location.

⑤ Change the data value.

⑥ Out of mode.

⑦ Unit