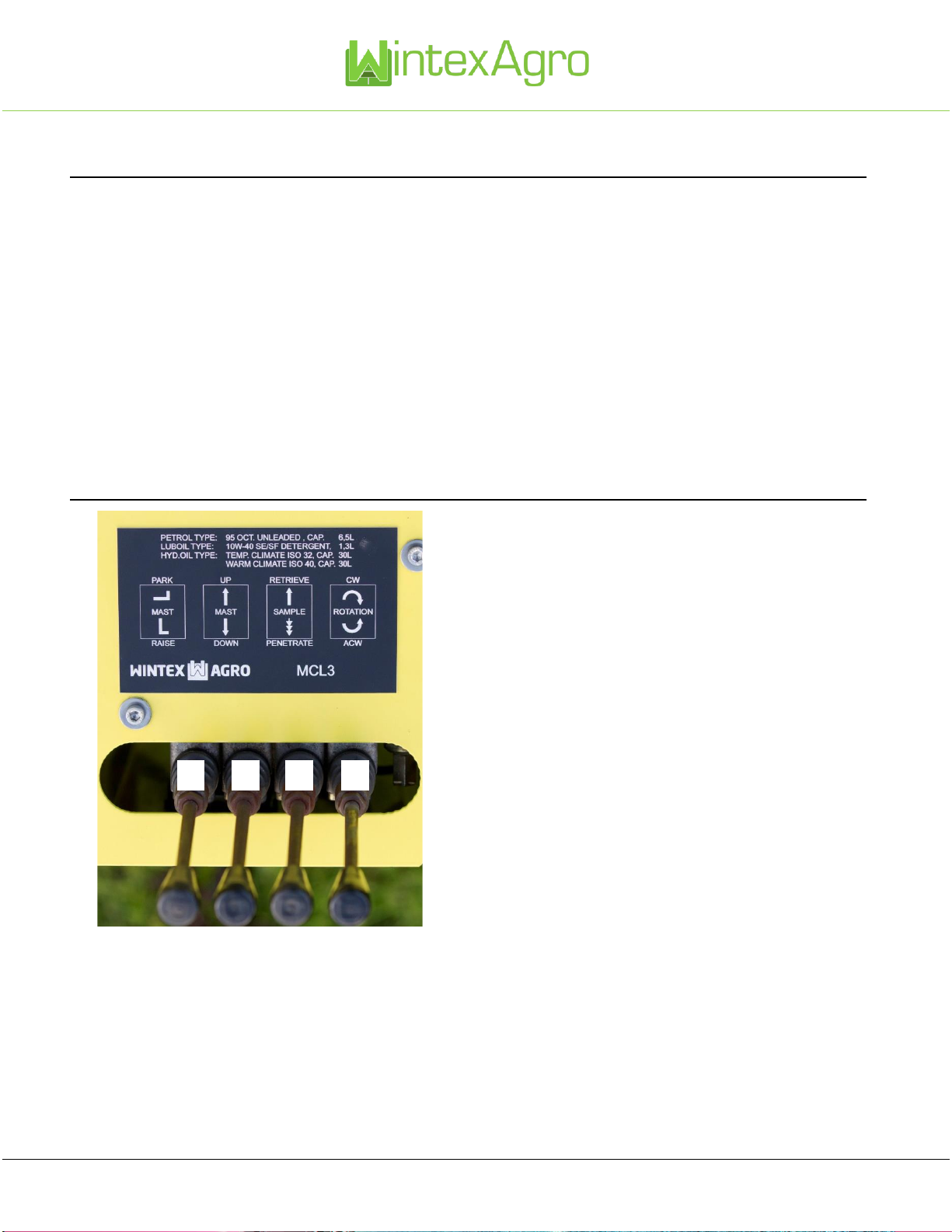

2.5. Using the valve lever second from left in penetrate mode (no. 3 on the picture above), carefully press the probe into the

ground until resistance is sufficient to start the hammer.

Note: Avoid hammering without resistance for long periods.

2.6. Give full opening to the valve in penetrate mode (push the handle down). The probe will penetrate the soil. When meeting

resistance, the hydraulic hammer will automatically start, and a synchronized sequence between the hammer and the cylinders

ensures optimum soil penetration without the operator’s need for participation.

2.7. When the probe has penetrated the soil down to the required depth, release the valve lever third from left (no. 3 on the picture

above) from the penetrate mode (mid position). Penetration will then cease.

2.8. Using the lever for rotation (no. 4 on the picture above), rotate the probe 180 degrees from side to side and stop it in the mid-

position.

2.9. Retrieve the sample by placing the valve lever (no. 3 on the picture above) into retrieve position.

2.10. Remove the soil sample from the slit by using the scraper so that the sample falls into the sampling scoop. It is common to

take soil samples for every 30 cm, e. g. 0-30 cm, 30-60 cm, 60-90 cm.

2.11. Empty the sampling scoop into the relevant soil bin. The soil of the samples can then be mixed and sent to the laboratory to

be analyzed.

3. REMOVING THE PROBE

Rotate the probe into a suitable position for removing the bolt for the probe. Remove one split pin, and then remove the bolt for the

probe. Relieve the pressure carefully by lifting the probe with your hand.

Be aware: The probe has sharp edges!

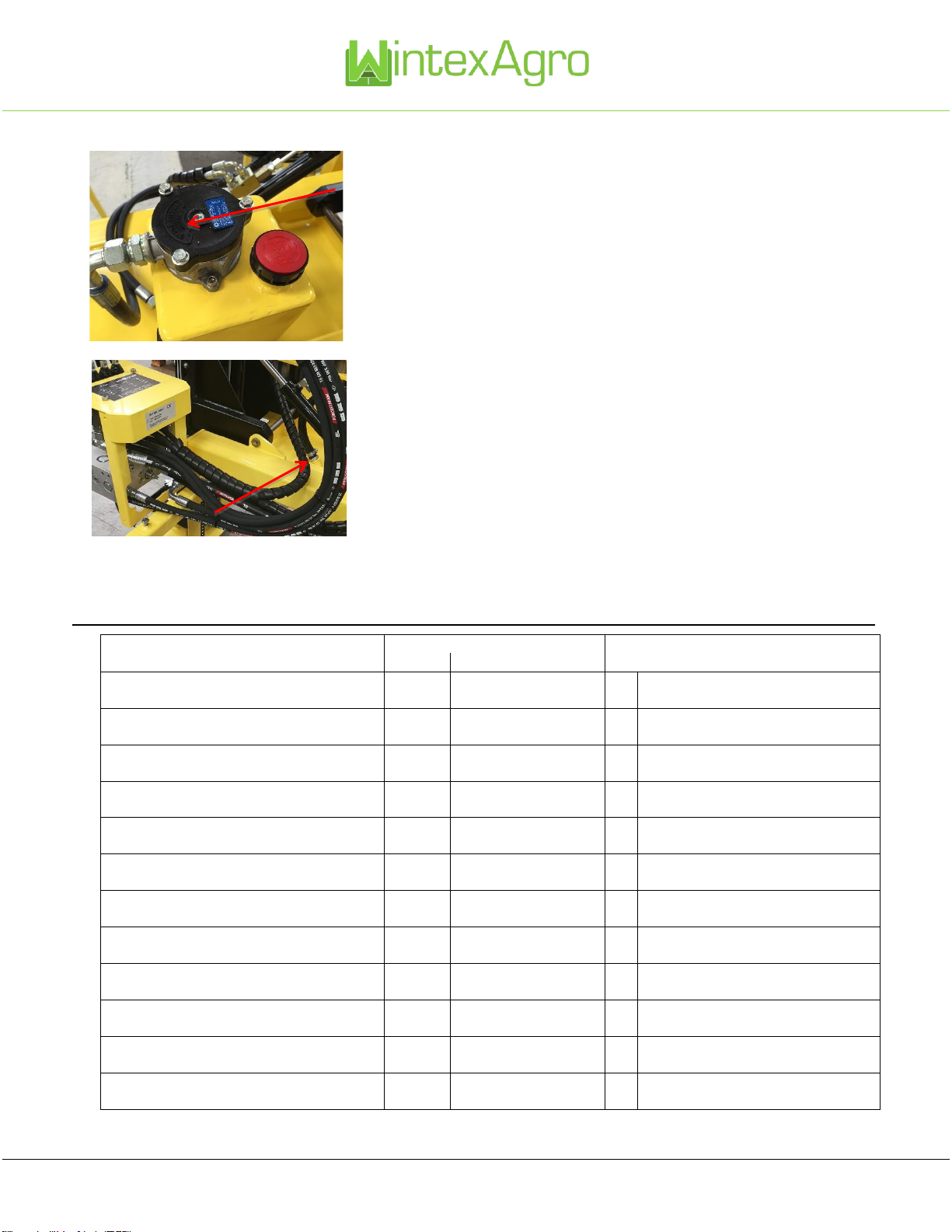

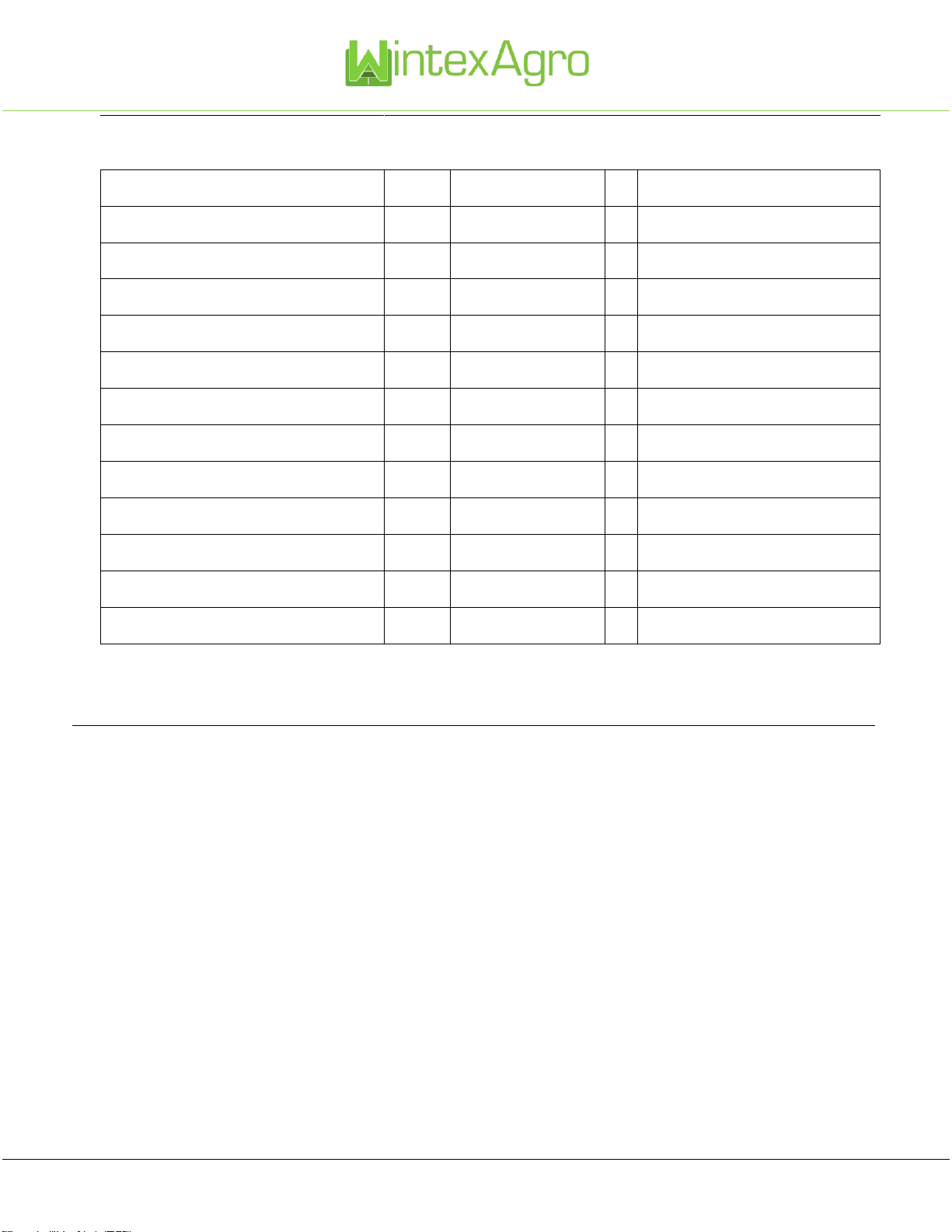

4. HYDRAULIC SYSTEM

The maximum system pressure should be set to 110-120 bar.

The operation of the probe is based on a combination of special valves in the valve block. When activating the valve lever

“penetration”, hydraulic oil is supplied to the two-stage pressure settings, low pressure and high-pressure setting. The low-pressure

stage actuates the cylinder downwards without hammer operation.

To adjust the two-stage pressure, the two-stage pressure valve must be screwed out as far as possible (anti-clockwise). With the

actuating lever set in penetration mode screw in the adjustment screw until the bottom plate of the soil sampler is just about to lift from

the ground. Lock the adjustment screw in this position.