Addendum October 2021 1146200

SMI 2 User Guide Rev. C Page 1

Contents

Specifications ................................................................................................................................................3

Main Menu....................................................................................................................................................4

Main Menu Icon/Button Selections..............................................................................................................5

Dashboard.....................................................................................................................................................6

Downtime......................................................................................................................................................7

Job Manager .................................................................................................................................................8

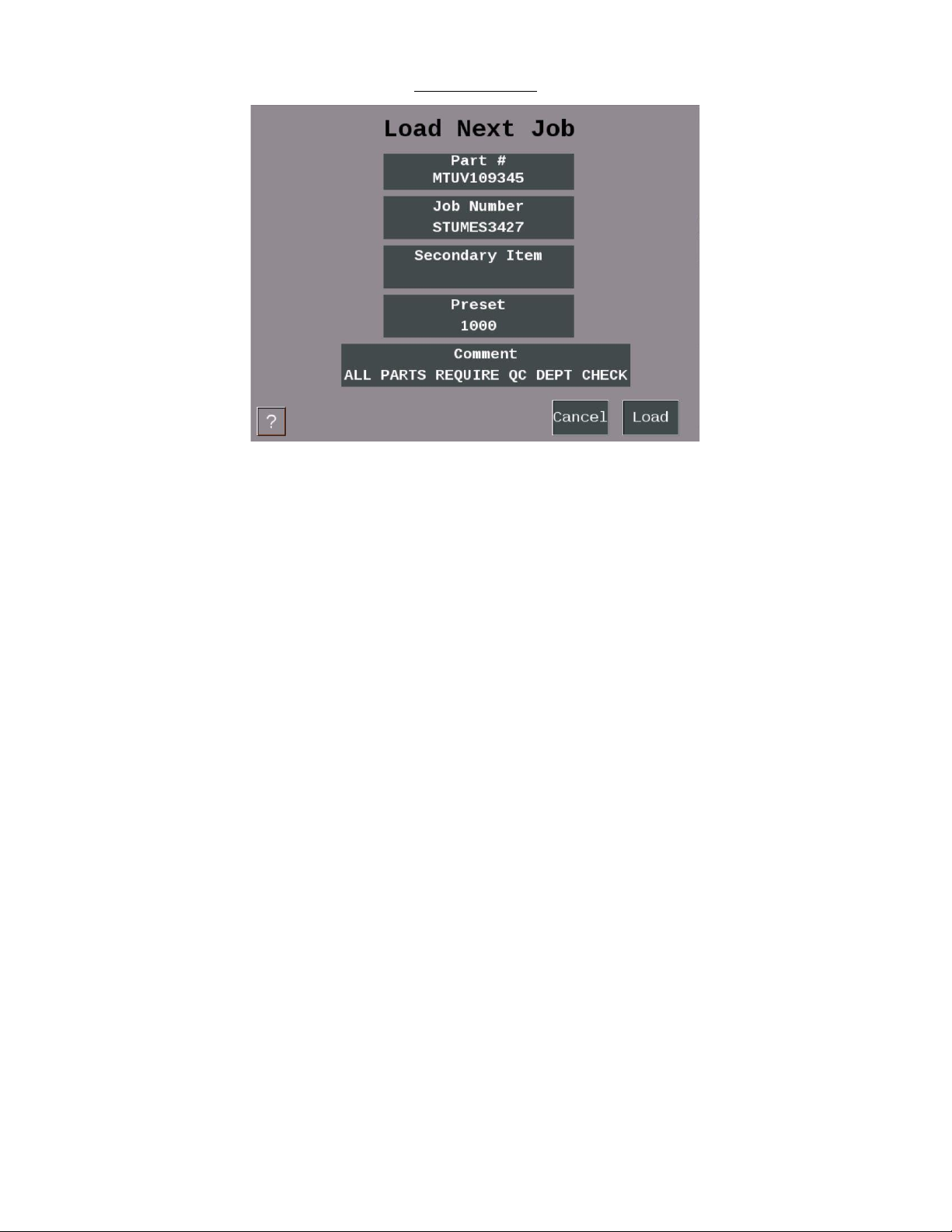

Load Next Job................................................................................................................................................9

Preset..........................................................................................................................................................10

Batch Segment Preset.................................................................................................................................11

Admin Menu ...............................................................................................................................................12

Security Settings..........................................................................................................................................13

Confirm Reset to Factory Defaults..............................................................................................................14

About SMI ...................................................................................................................................................15

Multipliers...................................................................................................................................................16

Utilities........................................................................................................................................................17

Additional Settings - Icon/Button Selections..............................................................................................18

Screen Defaults...........................................................................................................................................19

Forced Dialog Settings ................................................................................................................................20

Scanner Defaults.........................................................................................................................................21

Production Settings.....................................................................................................................................22

Input Settings..............................................................................................................................................23

Input Setup..................................................................................................................................................24

Cycle Input Setup ........................................................................................................................................25

Run/Idle Input Setup...................................................................................................................................26

Rate Calculation..........................................................................................................................................27

Analog Setup Menu.....................................................................................................................................28

Enable Inputs ..............................................................................................................................................29

Production Parameter Download ...............................................................................................................31

SMI 2 Job Manager Settings........................................................................................................................32

Forced Operator Login................................................................................................................................33

Network Settings.........................................................................................................................................34

Network IP Settings.....................................................................................................................................35

Wireless Settings.........................................................................................................................................36