WireCrafters, LLC.

WireCrafters, LLC.WireCrafters, LLC.

WireCrafters, LLC.

General Information

502/363-6691 www.wirecrafters.com

Louisville, Kentucky 40214

502/361-3857 FAX 1-800-626-1816

These Installation Instructions are provided as a guide for assembling Wi

reCrafters RapidGuard™

partition system. Due to varying job site conditions, and infinite layout possibilities, there is no

“recommended” or standard way to install the product.

Common sense and proper safety measures must be

used during installation.

The product may be unstable during installation; adequate temporary bracing

should be used until the layout is fully assembled with all fasteners and anchors properly tightened.

Depending on site and layout conditions, permanent field bracing to building s

tructure may be necessary.

Addition of field bracing is the responsibility of, and shall be done at installer’s or owner’s

discretion and expense. Installation problems arising from job site conditions should be referred to a

professional installer. Ref

er product assembly questions to WireCrafters.

Chalk line & marker Drill with adjustable clutch and 3/8” nut driver (2) Step ladders

Tape Measure Hammer Drill with 3/8” masonry bit (2) C clamps or Vise-Grip® type clamps

Level (2) 9/16” open end wrenches and/or #1 & #2 Phillips Screw Driver

Hacksaw (2) 9/16” deep socket ratchets 1/2” deep socket or 1/2” open end wrench

5/32” Allen Wrench 5/16” open end wrench 3/16” Steel drill bit

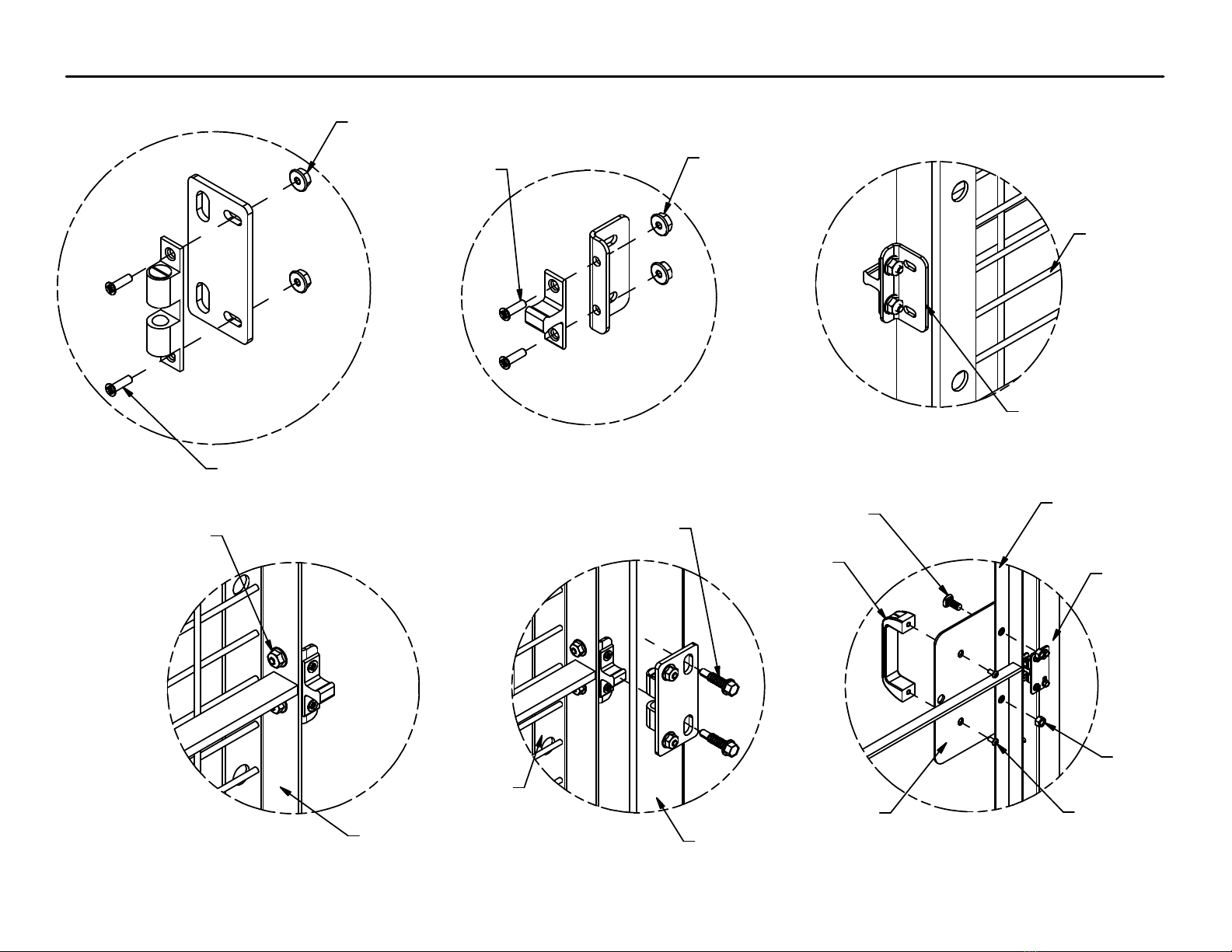

SELF DRILLING SCREW INSTALLATION RECOMMENDATIONS

hen installing self drilling screws use a standard variable speed screw gun equipped with an adjustable clutch or depth locating nose piece. Take care not

to over tighten or strip, set drill accordingly.

DO NOT USE IMPACT TYPE GUN WHEN INSTALLING SELF DRILLING SCREWS. Securely clamp

component parts in place before attaching with self drilling screws.

1. Installation is best accomplished with a two or three person crew.

2. Before starting, review all installation instructions pertinent to your layout (i.e. panels, doors, etc.)

3. “Face Side” of the partition is the outside.. “Inside” of the partition has one leg of the panel frame pointing in. Panel fastener hardware will be on

the inside of the partition.

4. Panels install vertically between posts, 2½” mesh opening should be parallel with floor.

5. Identify all panels by part number. If possible stage parts where they will be installed.

6. Special size panels have sticker tags on the angle and are referenced on drawing.

7. Make sure all posts are installed plumb (vertically perpendicular to floor). Shims (not provided) may be necessary.

8. Use a 4” spacer block (not provided) to support far end of panel during setup.

9. Begin installation process at a building wall, end or corner of layout.

10. Gauge hinge door opening width by installing header angle.

11. Gauge slide door opening by door width (e.g. 48” between posts for 4’ wide slide door). When necessary, slide door openings may be narrowed to

adjust length of adjacent run.

12. Standard hinge and slide doors are universal and may be installed left or right hand.

13. Installer should touch up all nicks, marks, and scratches with touch up paint provided.

- Page 2 -