INDEX

PAGE

En

gine

Models...................

..

...................

..

....

..

......

Illustration

of

Engines

..

..

.

..

.

..

..............................

3-4

Sectional

Drawing ..............................................

..

General

Information

and

Design

......................

..

Start

ing

and

Operating

Instructions

................

..

Horse

Power

..............

..

......,...............................

..

5

6

7

6

Safety

Precautions

............................................

..

11

Trouble-

Causes

and

Remedies

......................

13

Disassembling

and

Rea

ss

embling

..

................

..

14

Storage

of

Engine

for Winter ...... .... ....................

24

Parts

List

........

..

......................

.. ..

..........

....

........

..

26

Service

Station

Di

rect

ory,

See

bock

of

Manual

Carburetor

Repair-

See

Manufacturers

Bulle

tin

in

back

of

Manual.

Magneto

Repa

i

r-

See

Manufacturers

Bulletin

in

bock

of

Manual.

- - - - *

Air

Cleaner

7

Backfire

s

Through

Carburetor.

...........................

14

Battery

Igni

tion

Timer

......................................

..

11

Ca

mshaft

and

Valv

e

Tappets

..

.... ........ ..............

21

Carburetor

.........................................................

..

8

Clutc

h

Tok

e-Off ....

..

....

..

.... .... .... .... ......

..

..............

23

Clutch

Adjustment

..............

..

..........

..

.... ..............

24

Clutch

Reduction

Gears

......

..

..............................

24

Compression

........................................................

13

Compression

-

Rest

oring .............. ...... ......

..

....

..

11

Choke

.................................................................... 8

Cooling

....

.... ..

..............

..

................ ................

..

....

..

6

Ml-207 2

PAGE

Crankshaft

(

End

Ploy)..........................................

20

Electric

Starter

and

Generator

..

..

....

....

..

..

............

11

Engine

Speed

.......

:-..

............

..

..................

..

..............

22

Fuel

............................

..

..

....

..

....

..

............................ 8

Fuel

Pump

..

..........

..

................................................ 9

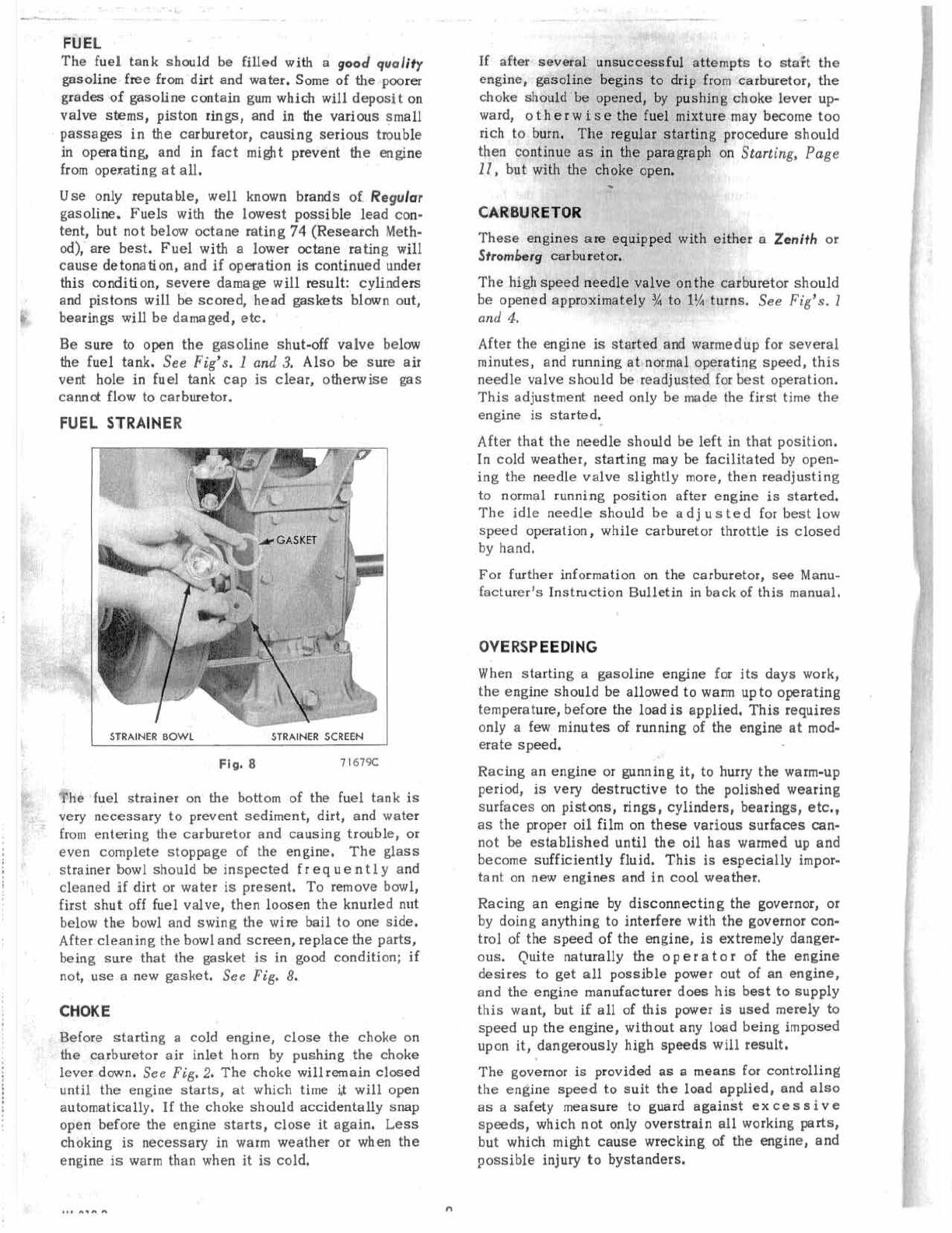

Fuel

Strainer

....

..

..............

..

.................. .................. 8

Governor

-

Adjustment

..

........

..

......................

..

....

22

Ignition

Switch

..

.................................................... 9

Ignition

Troubles

..................................................

14

Knocks

-

Engine

..

.... ...................................... ......

14

Lubrication

..

....

..

..

....

....

..

.... ....

..

.. .. ..

..

..

....

..

..

..

....

.. .. ..

7

Magneto .................................................................. 9

Magneto -lgn

it

ion Spark ..........................

..

.......... 9

Magneto-

Timing

..................................................

10

Magneto -

Drive

Shaft

and

Gear..............

..

..........

19

Oi

I - Grode

of

......................................................

..

7

Oil Pump ................................................

A..............

21

Over

speeding

.......................................................... 8

Overheats..

................................................

..

............ 14

Piston

and

Connecting

Rod..........

..

......................

16

Reduction

Gears

..

.............. ....

..

....

..

....

.... ................

24

Spark

Plug

...... ............................................

..

..........

10

Starting

-

Cronk

and

Rope

Starter

..........

..

..........

11

Starting

Difficulties

..

..

....

....

.. ..

.... ....

..

.................... 13

Stop

Engine

..

..

.... .. .. .. .. .. ....

..

..

..

.... ..

..

....

..

.. ..

..

....

........

11

Surging

or

Galloping....

..........................................

14

Valves

........................

..

....

....

................................

..

18

Valve

Tappet

Adjustment

....

..

..............................

19