1

Tel +82-2-300-2300

Fax +82-2-300-2400

Contents

1. General items...................................................................................................................... 2

1.1 Introduction.........................................................................................................................2

1.2 Application.......................................................................................................................... 2

1.3 Warranty.............................................................................................................................2

2. Warning............................................................................................................................... 3

3. Main specs..........................................................................................................................4

3.1 Explosion-proof...................................................................................................................4

3.2 Protection grade.................................................................................................................4

3.3 Temperature sensor types .................................................................................................4

3.4 Accuracy and tolerances.................................................................................................... 4

4. Design................................................................................................................................. 6

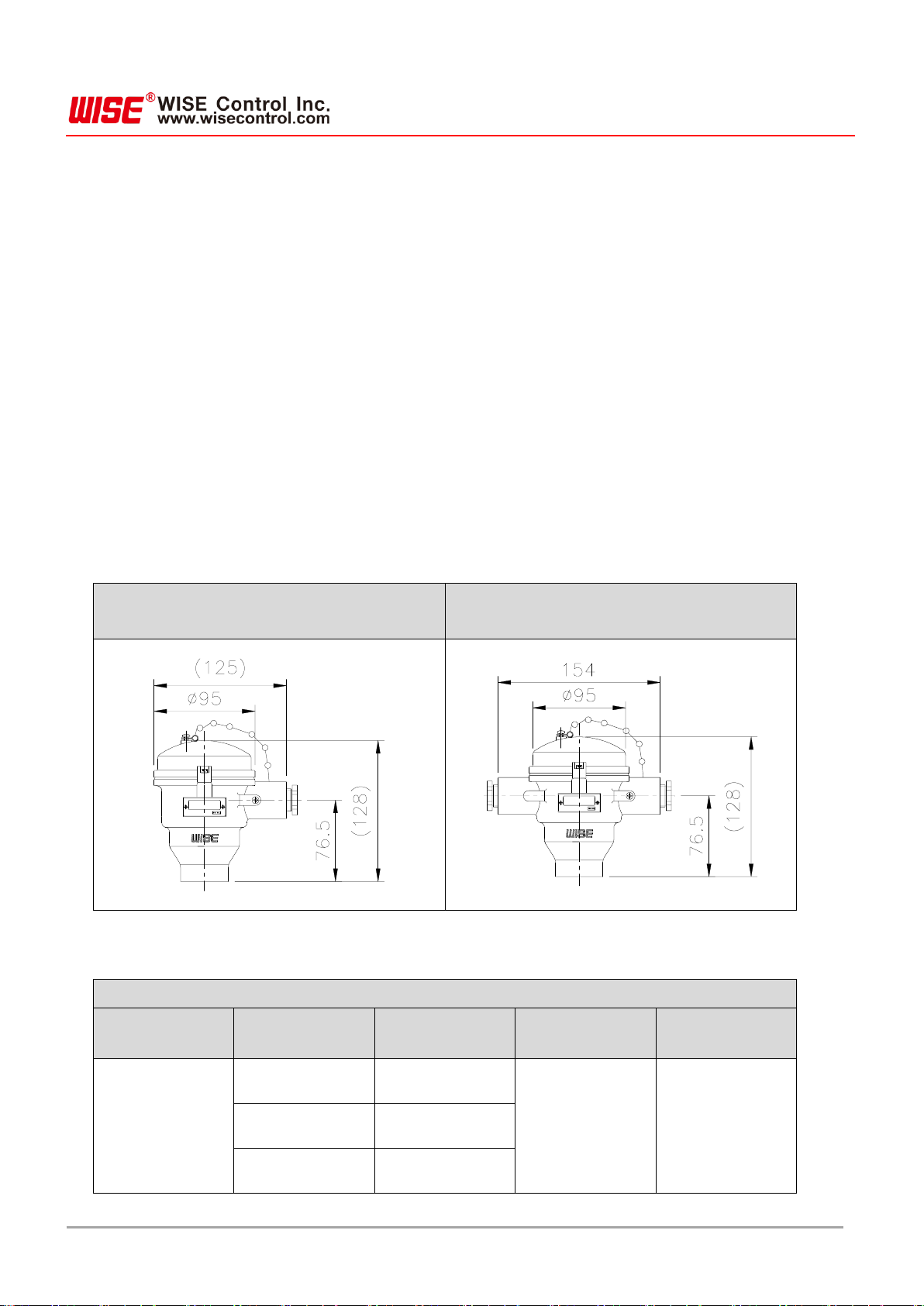

4.1 Structure.............................................................................................................................6

4.1.1 Spring loaded type ..........................................................................................................6

4.2 Head................................................................................................................................... 6

4.3 Detector unit and process connection unit material...........................................................7

4.4 Process connection unit..................................................................................................... 7

4.4.1 Sheathed cable (MI cable) type....................................................................................... 7

4.5 Relationship between process connection unit length and head temperature increase.... 8

5. Installation guide .................................................................................................................9

5.1 Pre-installation checks and precautions.............................................................................9

5.2 Installation requirement......................................................................................................9

6. Wiring ................................................................................................................................11

6.1 Extension & compensation wire....................................................................................... 11

6.1.1 Thermocouple(TC) ........................................................................................................11

6.1.2 Resistance thermometer detector(RTD)....................................................................... 11

6.2 Precaution for wiring.........................................................................................................12

6.3 Terminal block wiring........................................................................................................13

6.3.1 Thermocouple (TC) ....................................................................................................... 13

6.3.2 Resistance thermometer detector (RTD)...................................................................... 13

6.4 International color code table...........................................................................................14

7. Name plate........................................................................................................................15

7.1 Name plate indications..................................................................................................... 15

8. Repair and maintenance...................................................................................................16

9. Defect................................................................................................................................ 16

10.User’s duties......................................................................................................................17

11.Product return.................................................................................................................... 17