10

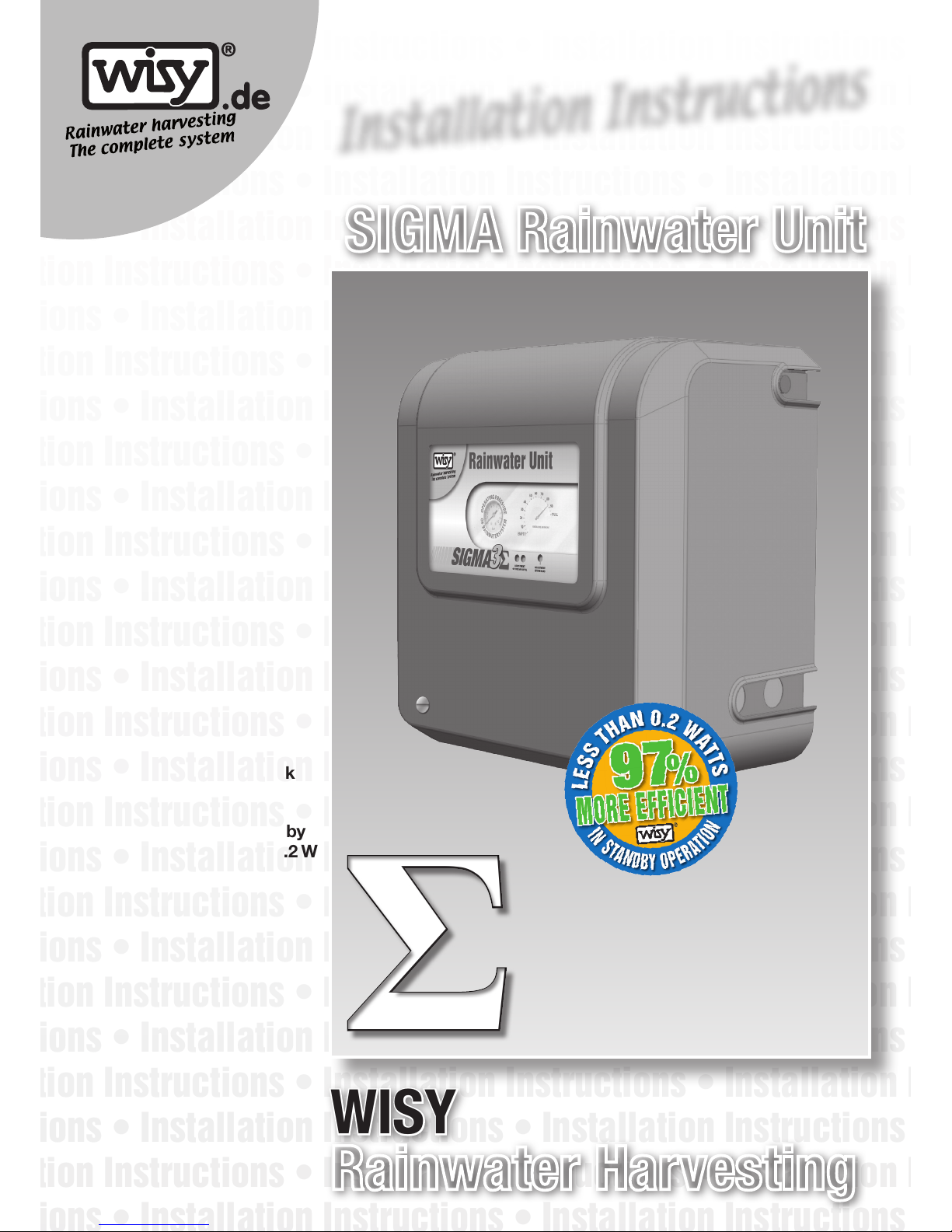

Applications

Mounting location

Installation instructions for measuring lead

Connect yellow measuring lead to

connector on the underside

of the SIGMA wall unit

Universal, pneumatic fill level meter with capsule-type element and integrated

electric pump for measuring fill levels in tanks. Steplessly adjustable to tank

heights of between 100 cm and 250 cm (adjustable by the hexagon socket

head screw); zero-point calibration of needle (adjustable by the Phillips-head

screw). Measuring accuracy of the measurement mechanism is +/- 3% of full

scale value. The electrically operated pump closes the measuring system at the

top dead point. The needle remains stationary briefly and then drops very slowly

down. The water stop air cushion produced in this way protects the capsule

element.

Universal connection for the measuring lead (PE tube) with 8 mm outer diameter.

Fill level is indicated in % irrespective of the tank shape.

Standard application is for water level height in the storage tank of between 100

and 250 cm and distances of around 10 m between the SIGMA wall unit with fill

level meter and the rainwater storage tank (measuring lead length 13 m). Positi-

on of normal use is vertical. Ambient temperature: 0°C to +40°C.

Protected against direct exposure to weather and solar radiation.

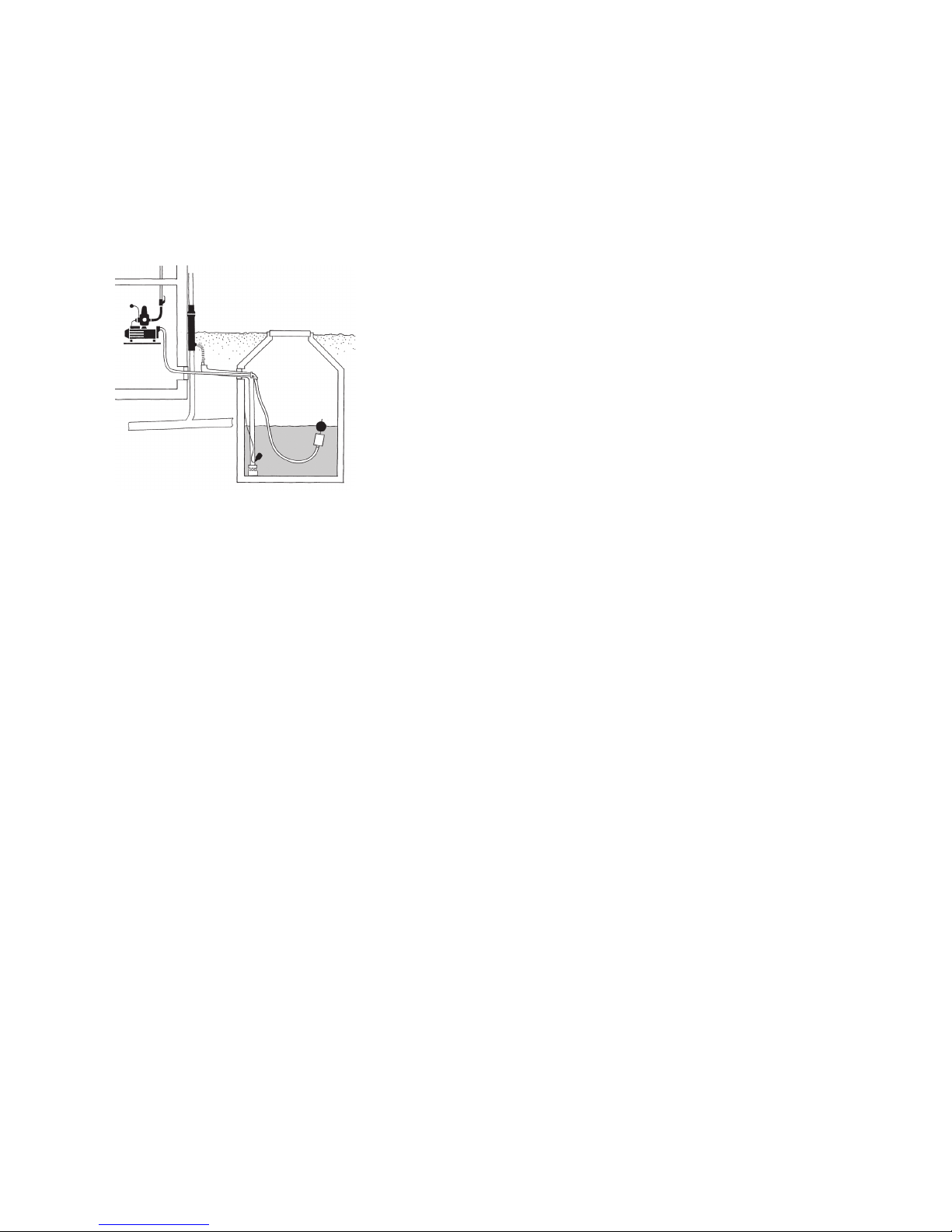

Install the measuring lead (yellow PE tube) with a continuous fall towards the

tank. Do not bend the lead (to prevent water pockets!).

Install the rubber-insulated measuring lead with brass weight in the storage tank

in such a way that it is suspended vertically and ends at approximately 5 cm

above the tank base, then connect both tubes with the brass coupling.

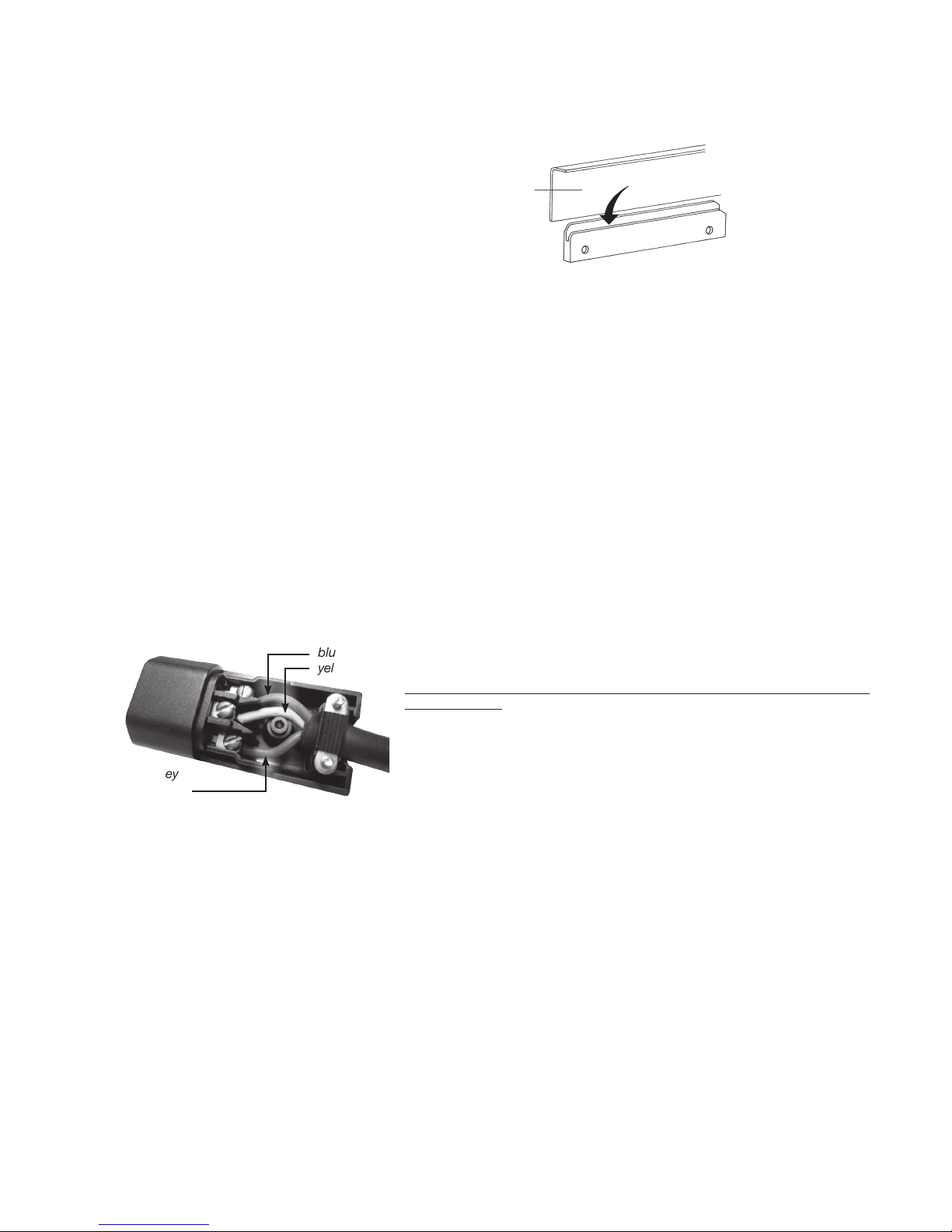

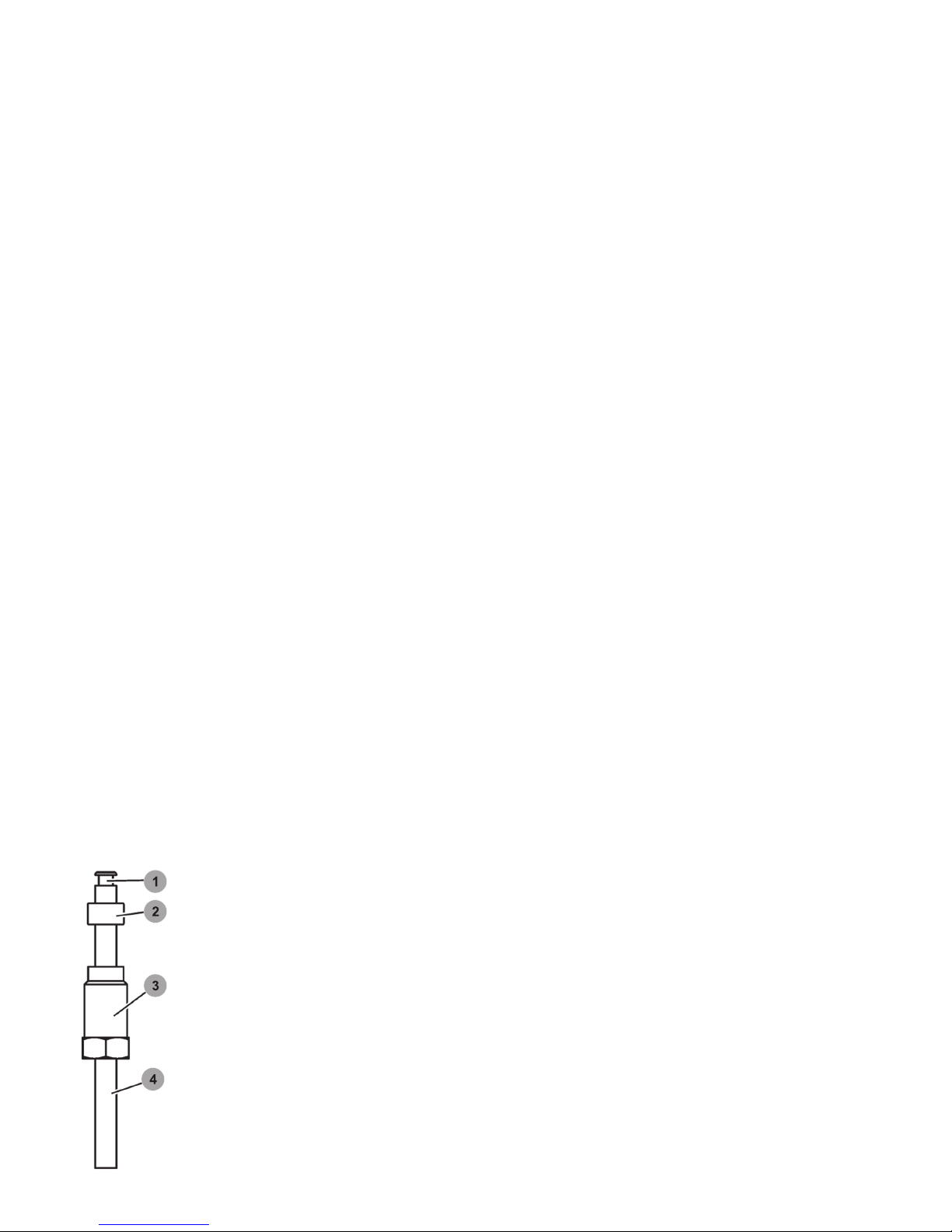

To connect the measuring lead to the measuring instrument connector (on the

underside of the SIGMA wall unit), assemble the individual components in the

order illustrated in Figure 1 at the end of the yellow PE tube, insert the tube as

far as it will go into the connector and gently tighten the hexagon bolt.

Device setting instructions

Remove the cover from the SIGMA unit.

Precisely adjust the measuring range (corresponds exactly to the maximum

water fill level in the storage tank up to the overflow) on the adjustment scale

using the hexagon socket head screw (failure to do this properly will result in

measuring errors!).

Use the zero-point calibration screw to position the needle at „0“. Turn the

screw by maximum one revolution to the left or right until the needle is pointing

to „0“. If the tank has already been filled and the pump started, the measuring

system will need to be „depressurized“ before the zero point can be calibrated.

This can be done by detaching the measuring lead from the connector at the

wall unit.

Description of level indicator unit

A measurement of the fill level of the storage tank is triggered only if the SIG-

MA pump starts up. During the pneumatic measuring process, the hydrostatic

pressure is measured. This varies depending on the water level in the tank. The

pressure is generally measured at a height of 5 cm above the tank base and is

converted to a fill level percentage on the clock dial.

The pump of the measuring instrument is used to build up pneumatic pressure in

the measuring system until this pressure is equal to the water pressure applied

to the base of the tank. The needle is now in its maximum position. The pressure

generated by the pump has displaced the water column from the measuring

lead suspended in the water (black rubber hose). Bubbles of air escape from

the end of the hose on the tank base and the needle remains temporarily in the

measurement position. Once the SIGMA has returned to its „normal position“,

the needle gradually drops back to the „0“ position.

Description of function

Level indicator

Scope of supply of basic equipment

SIGMA with level indicator

This description applies to installation of a pneumatic level indicator in the SIG-

MA rainwater unit. The function descriptions of the measuring instrument, the

installation instructions for the measuring lead and the device setting instruc-

tions are all important.

PE measuring lead (yellow), a brass hose coupling, 3 m rubber-insulated tube

(black) with brass weight and a connection kit for the measuring lead (small

parts supplied in small plastic bag).

Replacement / extension kits, each containing 10 m of PE measuring lead with

brass hose coupling, can be ordered (WISY Item No. FA 9915).

A connection kit

includes:

1. Brass tubular rivet

(as „support“)

2. Rubber seal

3. Hexagon bolt (black

plastic) with hole to insert

yellow measuring lead; is

screwed into connector

on wall unit

4. Yellow measuring lead