Page 2 of 23

WITT-GASETECHNIK GmbH & Co KG

Gas Safety- & Control Equipment

1 Table of contents

1Table of contents......................................................................................................... 2

2Notes on this manual.................................................................................................. 3

2.1 What does this manual contain?.........................................................................................................3

2.2 Rights to this manual...........................................................................................................................3

2.3 What symbols are used?.....................................................................................................................3

3Safety instructions and precautionary measures .................................................... 4

3.1 General safety instructions..................................................................................................................4

3.2 Liability.................................................................................................................................................4

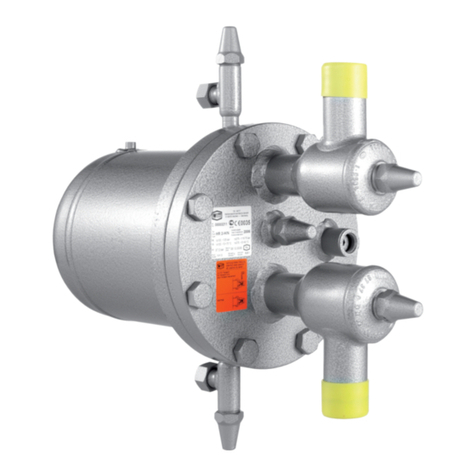

4Description of alternative control «Leak-Master®Easy Plus»................................. 5

5Setting up and installation ......................................................................................... 6

5.1 Checking for transport damage...........................................................................................................6

5.2 Place for setting up..............................................................................................................................6

5.3 Electrical installation............................................................................................................................6

5.4 Installation of the hose connections....................................................................................................7

5.4.1 Use of the both enclosed adaptors (hose 8 mm 12 mm).................................................8

6Operation ..................................................................................................................... 9

6.1 Switching the device on.......................................................................................................................9

6.2 The touch screen display ....................................................................................................................9

6.2.1 Entering and editing data.........................................................................................................9

6.2.2 Navigation in data lists...........................................................................................................10

6.3 User selection....................................................................................................................................10

6.4 Product-overview...............................................................................................................................11

6.5 Testing products................................................................................................................................12

6.6 The menu «Product-Management»...................................................................................................13

6.6.1 Delete product........................................................................................................................13

6.6.2 Create a new product.............................................................................................................14

6.7 The menu «User Administration»......................................................................................................14

6.7.1 Delete user.............................................................................................................................15

6.7.2 Create new user.....................................................................................................................15

6.8 The menu «Data administration»......................................................................................................16

6.9 The menu «Options».........................................................................................................................17

6.9.1 Set language..........................................................................................................................17

6.9.2Set date and time...................................................................................................................17

6.9.3 Barcode set-up.......................................................................................................................17

6.9.4 System options.......................................................................................................................17

6.10Switching the device off.....................................................................................................................18

6.11Malfunctions and rectification............................................................................................................18

6.11.1 Malfunction table....................................................................................................................18

7Connection to a PC................................................................................................... 19

7.1 Establish a LAN connection ..............................................................................................................19

7.2 Data exchange ..................................................................................................................................20

7.2.1 Copy data from the control system to PC..............................................................................20

7.2.2 Copy data from the PC to control system..............................................................................21

8Technical Data........................................................................................................... 22

9Parts List.................................................................................................................... 23