Table of Contents

Section 1 - THEORY OF OPERATION............................................................................................................. 5

Section 2 - SPECIFICATIONS ......................................................................................................................... 7

2.1 - Features ............................................................................................................................................ 7

2.2 –Power and Load Ratings................................................................................................................... 7

2.3 –Electrical Protection ......................................................................................................................... 7

2.4 –Environmental Ratings ..................................................................................................................... 8

2.5 –Electrical Noise................................................................................................................................. 8

2.6 - Enclosures ......................................................................................................................................... 8

2.7 - Weight............................................................................................................................................... 8

2.8 - Dimensions........................................................................................................................................ 8

2.9 –Reliability ......................................................................................................................................... 8

2.10 –Codes and Standards...................................................................................................................... 8

Section 3 –CONTROL OPERATION MODES ................................................................................................. 9

3.1 –Control Modes.................................................................................................................................. 9

3.2 –Other Modes of Operation............................................................................................................... 9

Section 4 –INPUTS/OUTPUTS.................................................................................................................... 10

4.1 –Analog Inputs ................................................................................................................................. 10

4.2 –Digital Inputs .................................................................................................................................. 10

4.3 –Analog Outputs .............................................................................................................................. 10

4.4 –Digital Outputs ............................................................................................................................... 11

Section 5 –INSTALLATION ......................................................................................................................... 12

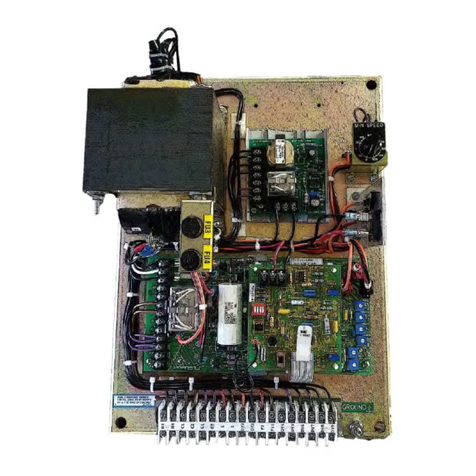

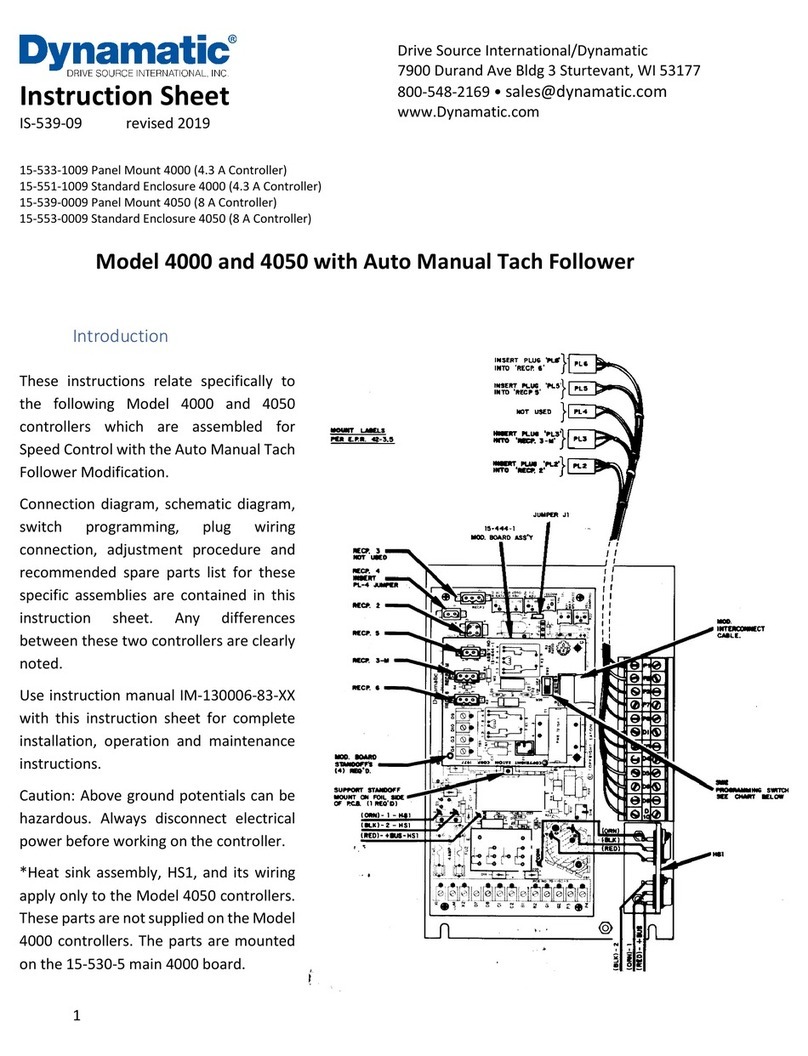

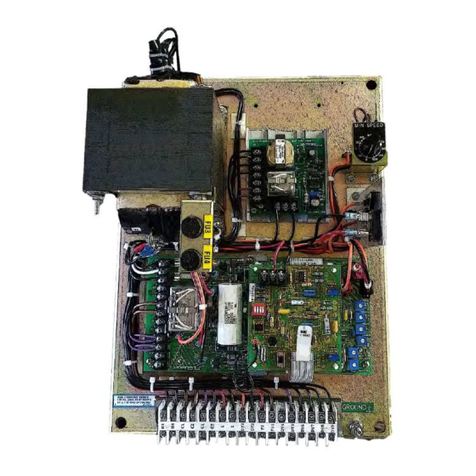

5.1 –Mounting Hardware....................................................................................................................... 15

5.2 –Wiring............................................................................................................................................. 16

5.3 –Hardware Setup ............................................................................................................................. 20

Section 6 –KEYPAD .................................................................................................................................... 22

Section 7 –PROGRAMMING ...................................................................................................................... 23

7.1 –Menu A: Control Setup................................................................................................................... 23

7.2 –Menu B: Clch Performance ............................................................................................................ 28

7.3 –Menu C: Accel/Decel Setup............................................................................................................ 29

7.4 –Menu D: Brake Performance.......................................................................................................... 29

7.5 –Menu E: Follower Setup ................................................................................................................. 30