5

a

b

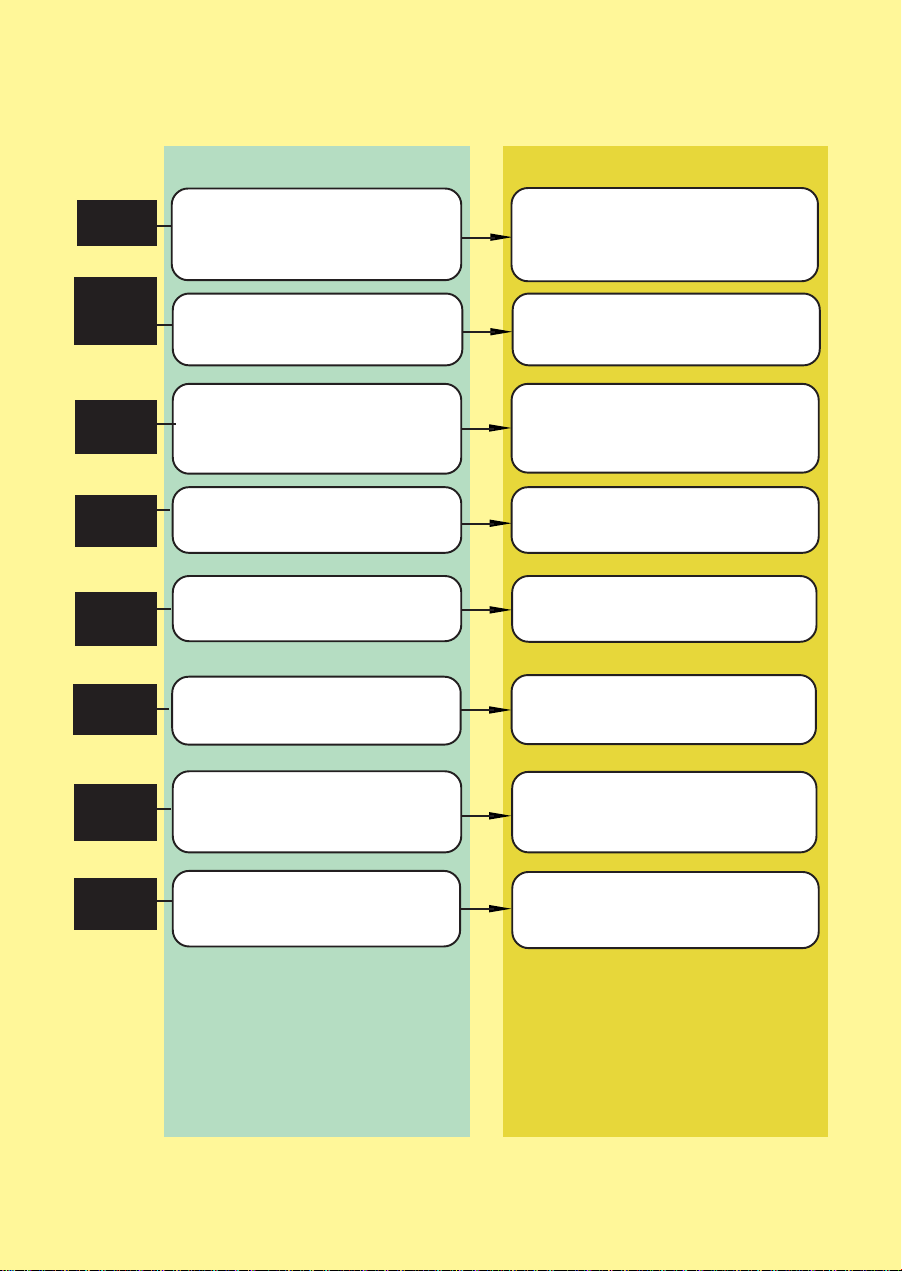

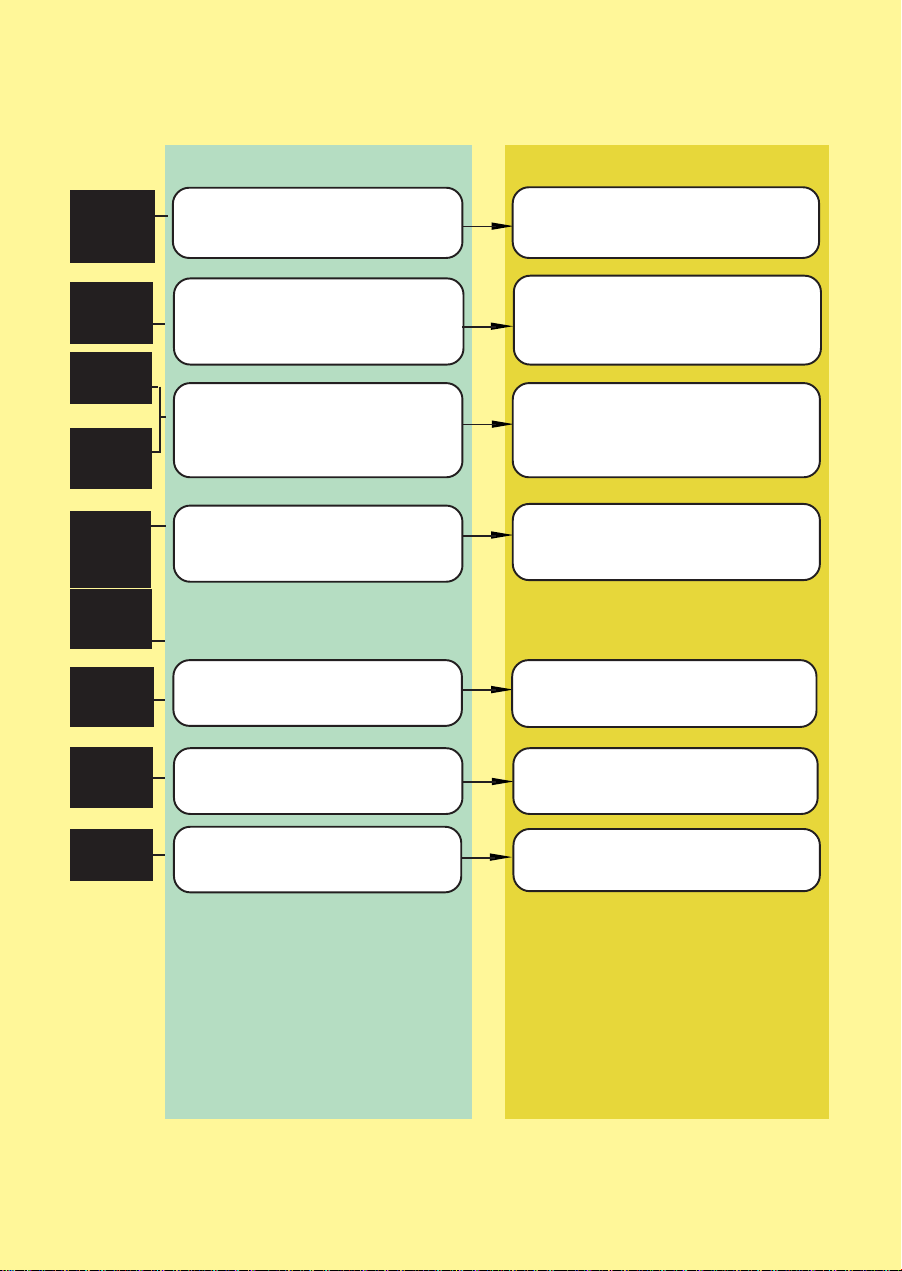

Regular Cleaning *)

17

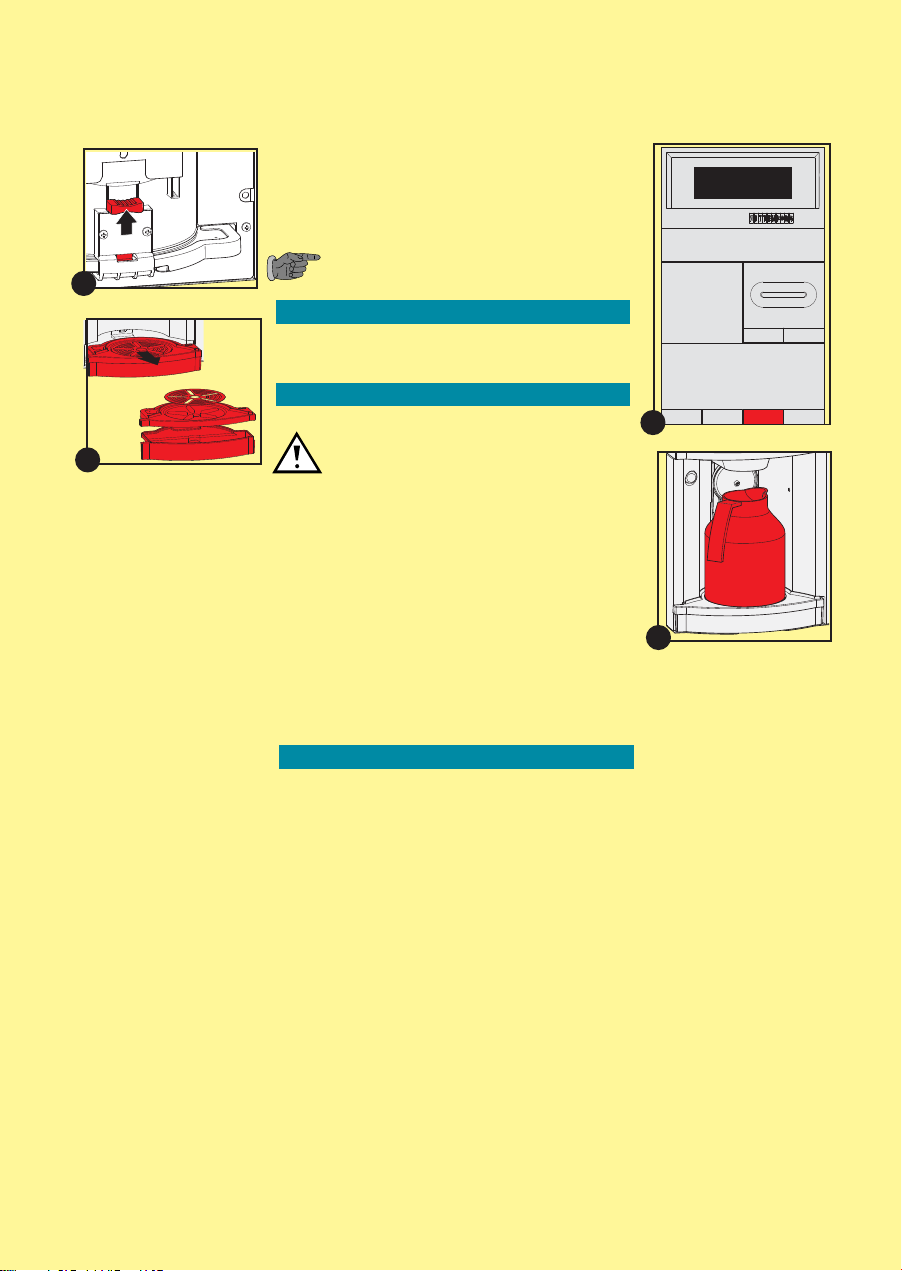

Opening

• Open the door (turn key clockwise)

(1)

.

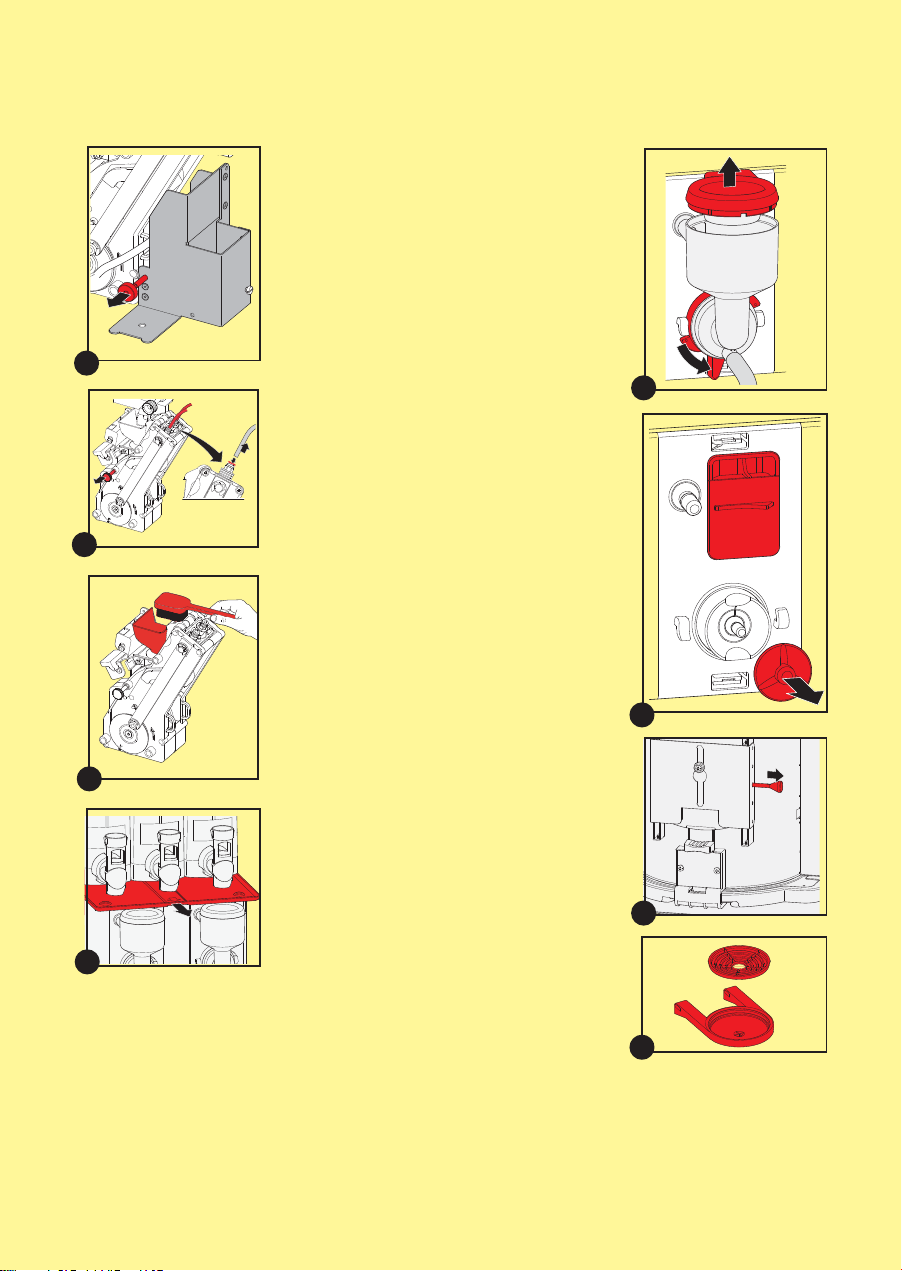

Coffee waste containers

• Take out waste containers

(2)

. If used,

remove plastic bag from the solid waste

container.

• Remove the liquid container, empty it and

wipe it clean. Wipe dry sensors

(3)

.

• Wipe clean solid waste container, relocate

liquid waste container and, if used, insert a

new plastic liner.

• Leave waste containers outside of machine.

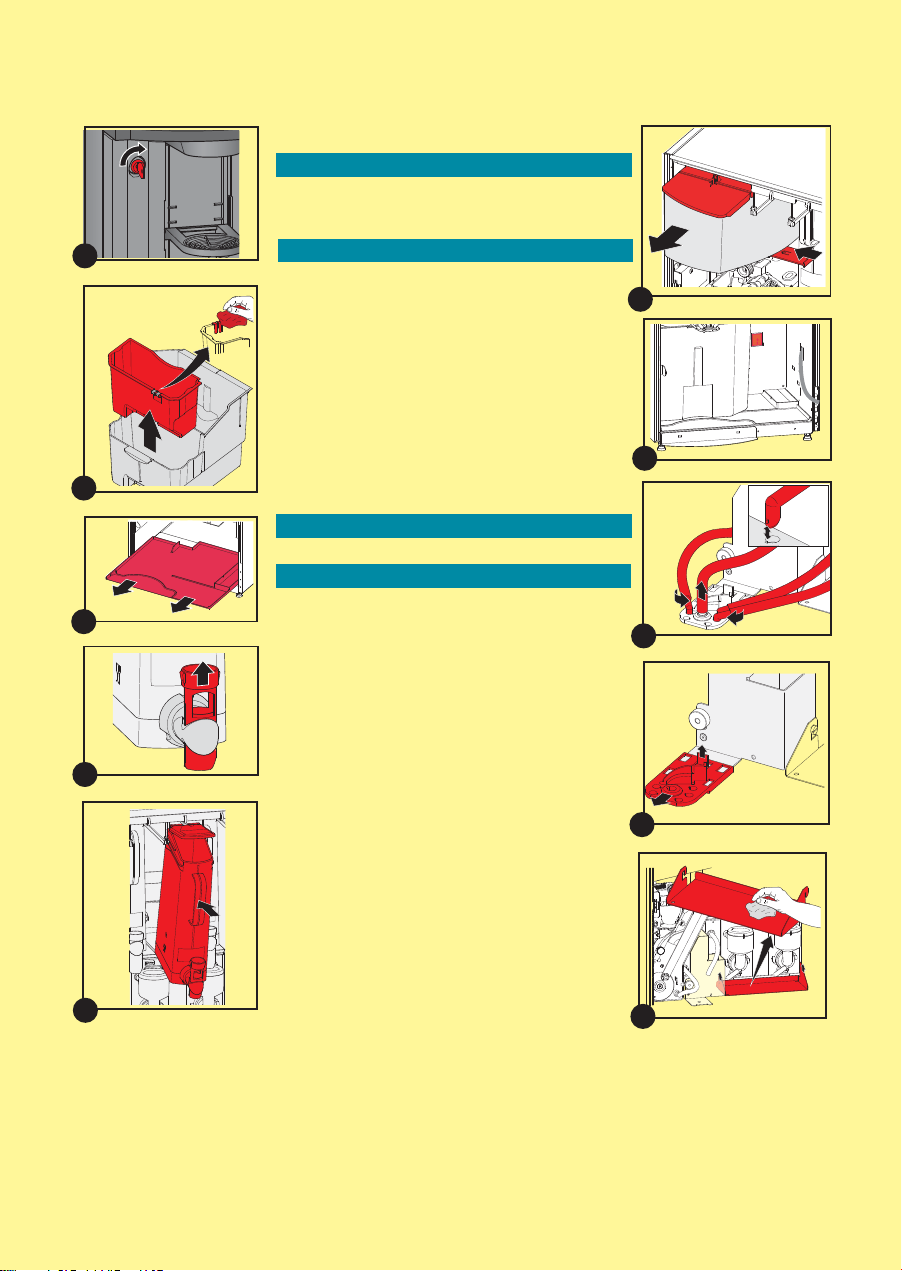

Ingredient canisters

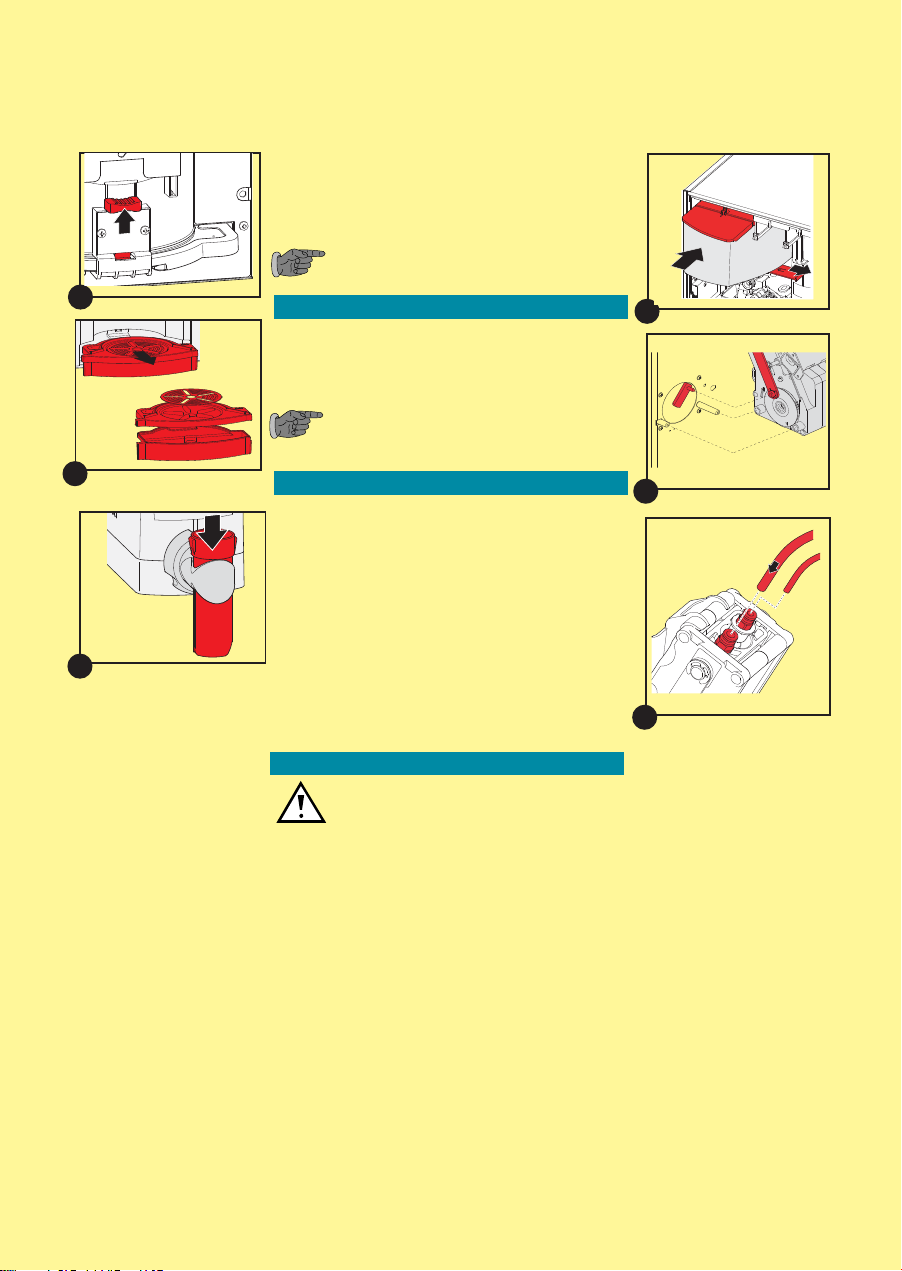

Instant ingredient canisters

• Pull base tray

(4)

forward.

• Push the outlet tubes upwards to close the

outlet spouts of the canisters

(5)

.

• Take the canisters by the handles and pull

them forward to the end stop in guiding rails

(6)

. The lids are automatically triggered open.

• If required, the canisters can be removed by

lifting canisters upwards and pulling forwards

over the end stops in guiding rails

• Fill canisters with ingredients.

• Press lid slightly down and push back

canisters.

• Push the outlet tubes downwards to open

the outlet spouts of the canisters

(7)

.

• Push base tray back in place.

Coffee bean canister

• Open lid

(8)

and fill canister with coffee

beans.

• Put lid back on.

Cleaning parts

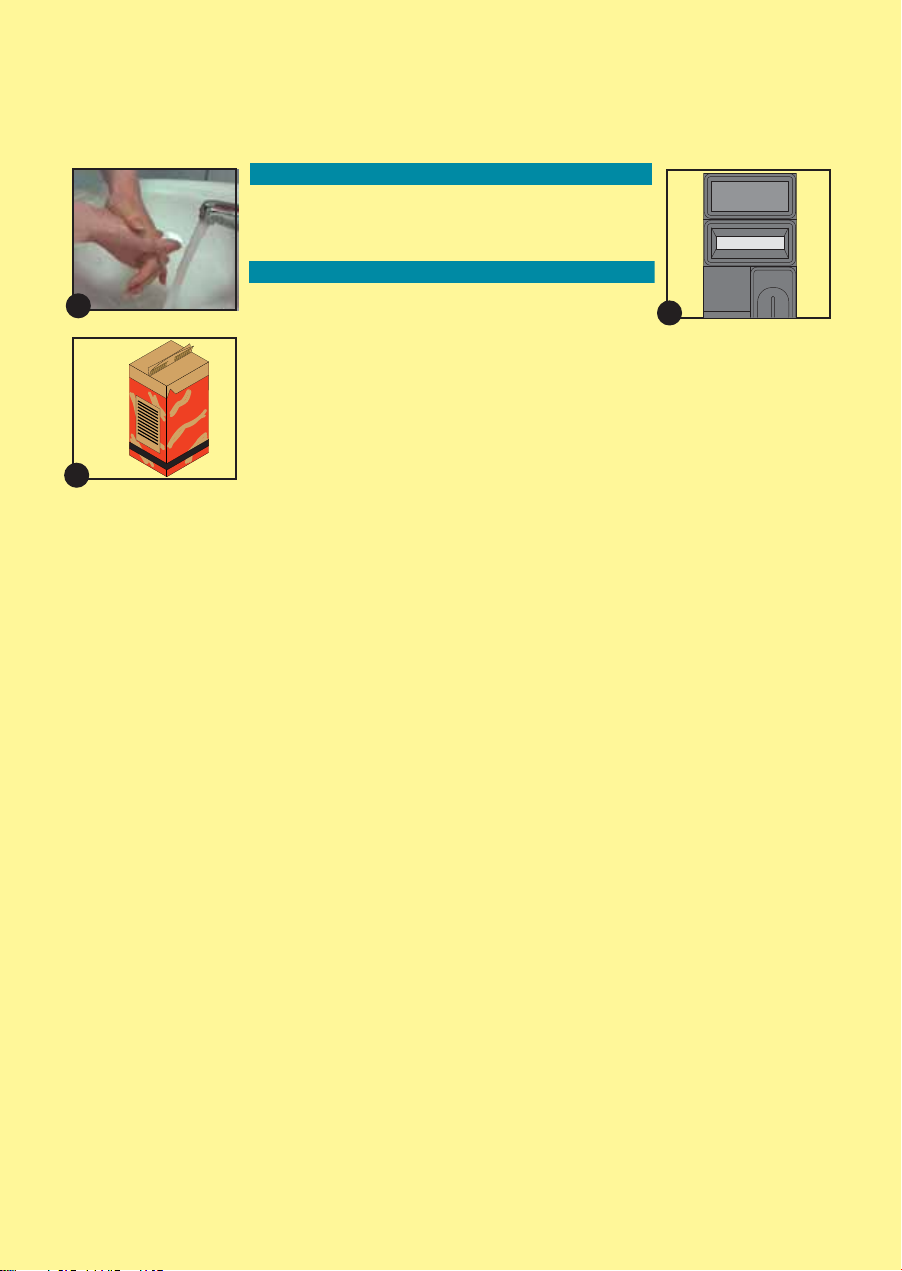

Cup carrier

It is recommended to have the cup carrier

as an exchange kit (hygiene kit).

• Remove cup carrier: Take hold of the cup

carrier with your right hand

(9)

and remove

the corresponding retaining pin

(10)

, situated

on the rear side of the cup station, with your

left hand.

• Clean the drip grid

(11a)

and tray

(11b)

in

hot water with cleaning agent and dry parts.

9

8

*) All parts to be cleaned regularly are

designed in a light blue colour. All parts

of action are supplied in a green colour.

(see overleaf))

11

10

3

2

5

6

4