5

Regular Cleaning *)

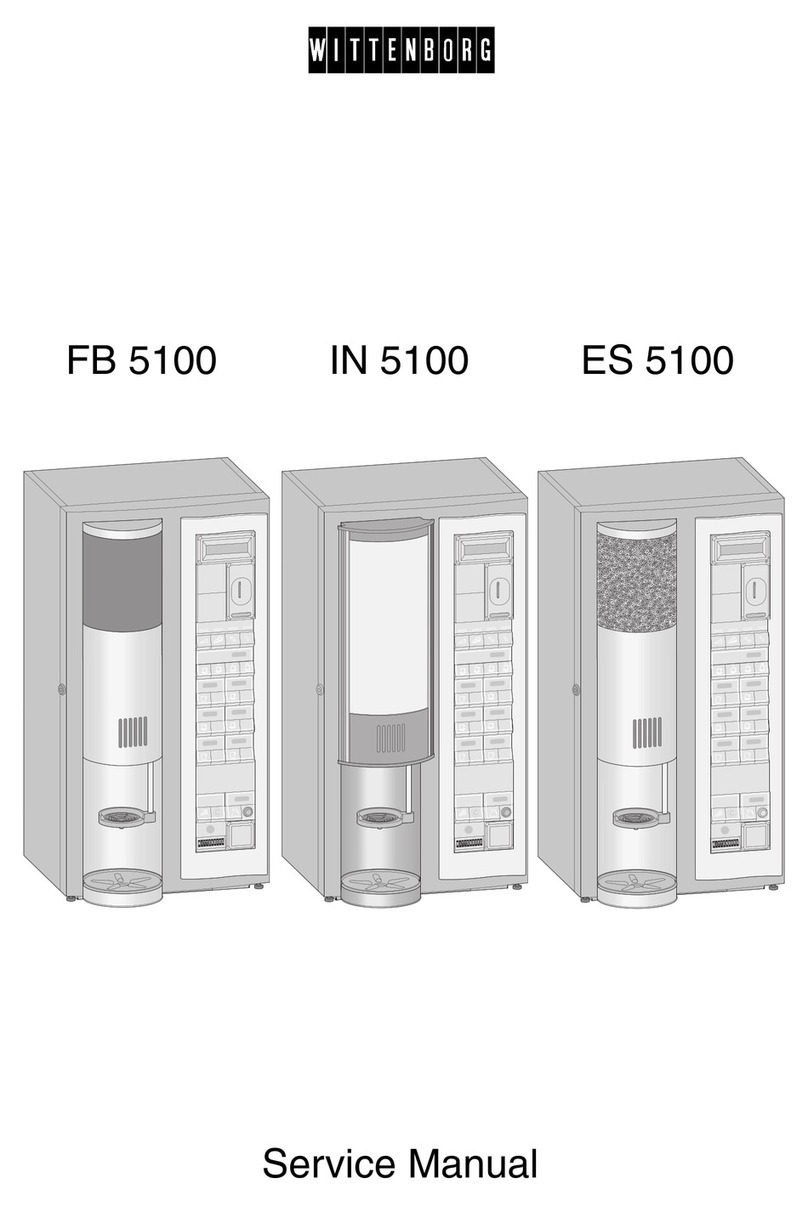

1

3

4

6

Opening and disconnecting

•Open the door by turning key clockwise (1).

Ingredient canisters

•Pull forwards solid waste container (2).

•Pull base tray (3) forwards.

Instant ingredient canisters

•Push the outlet tubes upwards to close the

outlet spouts of the canisters (4).

•Take the canisters by the handles and pull

them forwards to the end stop in guiding rails

(5). The lids are automatically triggered open.

•If required, the canisters can be removed by

lifting canisters upwards and pulling forwards

over the end stops in guiding rails

•Fill canisters with ingredients.

•Press lid slightly down and push back

canisters.

•Push the outlet tubes downwards to open the

outlet spouts of the canisters (6).

Freshbrew ingredient canister

•Pull forwards freshbrew ingredient canister (7)

approx. 30 mm.

•Open lid (8) and fill canister with coffee.

•Close lid.

•Push back canister in place. Check to make

sure that it is locked in place.

Cleaning parts

Solid waste container

•Take out solid waste container. Empty

container and insert a new liner.

•Push base tray back in place.

Cup carrier

It is recommended to have the cup carrier as

an exchange kit (hygiene kit).

•Remove cup carrier: Take hold of the cup

carrier with your right hand (9) and remove

the corresponding retaining pin (10), situated

on the rear side of the cup station, with your

left hand.

•Clean the drip grid (11a) and tray (11b) in

hot water with cleaning agent and dry parts.

8

7

2

*) All parts to be cleaned regularly are

designed in a light blue colour. All parts

of action are supplied in a green colour.

(see overleaf))

5

11

10

a

b

9