Content

Table of Contents

1. iAStar AS380..................................................................................................1

Characteristic...................................................................................................1

scope of operation...........................................................................................1

2.Overview of system.........................................................................................3

Integrated frequency converter iAStar AS380................................................3

Car controller panel SM02..............................................................................3

Command board panel SM03..........................................................................3

Display & control board SM04.......................................................................3

Special board SM09........................................................................................4

Functional overview........................................................................................4

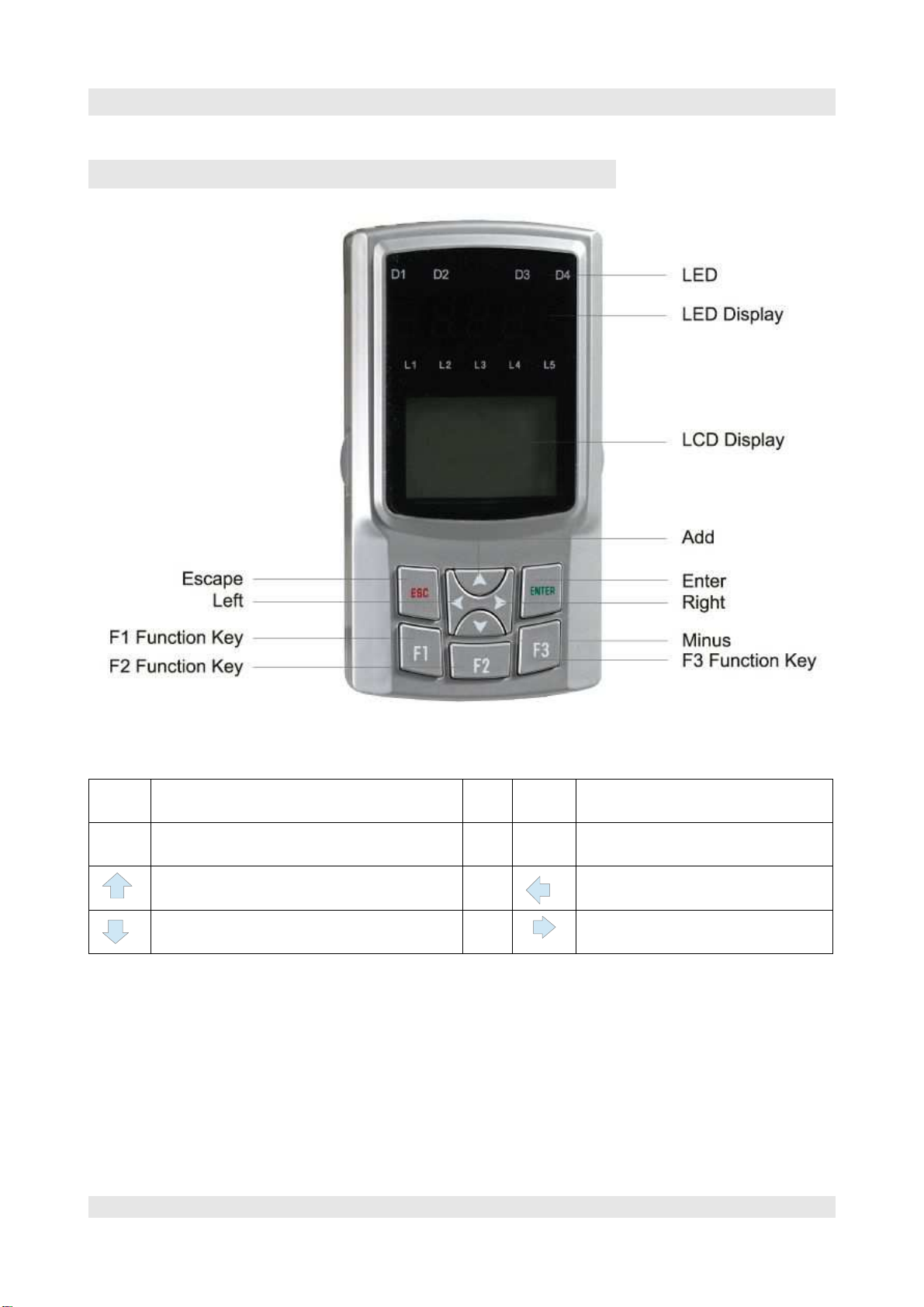

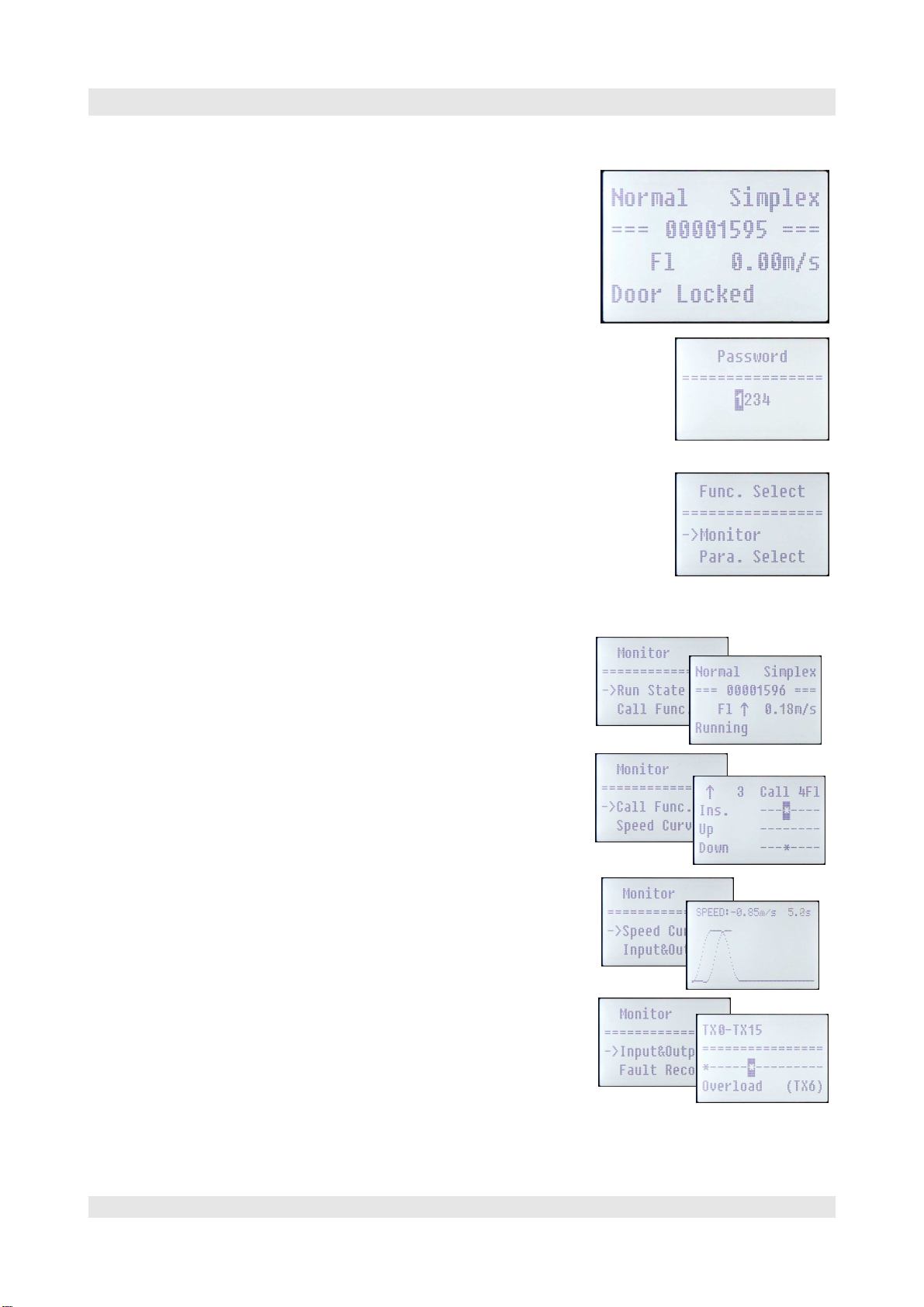

3. Hand device....................................................................................................7

operation:.........................................................................................................8

Log in:..............................................................................................................8

Menu................................................................................................................8

State menu under „Monitor“..........................................................................8

To set parameter in the submenu Para.Select..................................................9

different functions (Func.Select)...................................................................11

4. Menu tree & parameter..............................................................................13

Basic Parameter.............................................................................................15

Comfort Adjust:S-Curve...............................................................................15

Comfort Adjust: PI Adjust............................................................................16

5. Commissioning -Installation run................................................................17

Condition for commissioning run:................................................................17

Groupfunction................................................................................................18

Security loop – Return-motion -control........................................................18

First movement with the Return-motion -control..........................................18

Setting the parameters on AS.T030...............................................................18

Checking parameters for commissioning and eventually adapt....................20

Parameter speed controller............................................................................22

HDR Lock Error............................................................................................23

6.shaftcopying..................................................................................................25

Re-levelling -sensor.......................................................................................26

Magnetic switch............................................................................................26

Correction switches.......................................................................................26

Inspection endswitches..................................................................................26

Intelligent Magnetic sensors iMS45...........................................................27

Design and function.......................................................................................27

Correct signal Inputs at AS.T030 (LEDs)....................................................28

7.AS380 Main board AS.T029........................................................................31

AS.T029 connections:...................................................................................31

8.SM02/H cartop box module.......................................................................35

9.SM09IO/B Add-ON module.......................................................................37

10.SM02/G car panel board-module.............................................................39

SM03 button-module.....................................................................................40

11.SM04HRF floor module.............................................................................41

12.Security Section..........................................................................................43