Contains

1. Safety and assembly rules .................................................................................................... 3

1.1. Safety rules.............................................................................................................................. 3

1.2. Assembly recommendation..................................................................................................... 3

2. Device description................................................................................................................ 4

2.1 Intended use and properties................................................................................................... 4

2.2 Features................................................................................................................................... 5

2.3 Description of connectors and diodes..................................................................................... 5

2.4 Power supply ........................................................................................................................... 6

2.5 Force sensors connection........................................................................................................ 6

2.6 Insulated inputs....................................................................................................................... 7

2.7 Transistor outputs ................................................................................................................... 7

2.8 Analog output 0-10V/4-20mA................................................................................................. 7

3. Transducer configuration...................................................................................................... 8

3.1 Connection by USB .................................................................................................................. 8

3.2 Configuration of strain gauge inputs and measurements....................................................... 8

3.2.1 Example of configuration ................................................................................................ 9

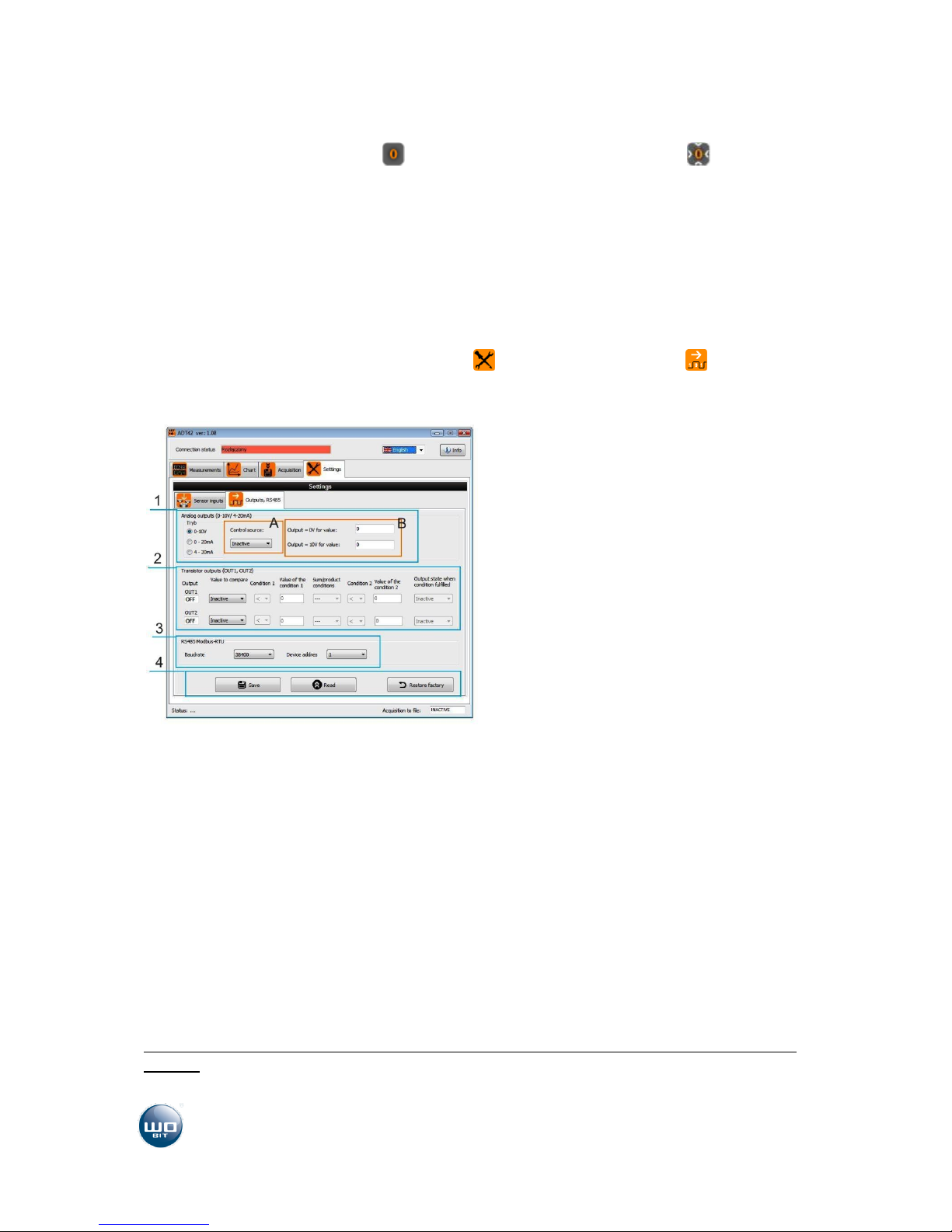

3.3 Configuration of output and RS485....................................................................................... 10

3.3.1 Configuration of analog output..................................................................................... 10

3.3.2 Configuration of transistor outputs............................................................................... 11

3.3.3 Configuration of RS485 MODBUS.................................................................................. 11

4. RS485 MODBUS Communication......................................................................................... 12

5. Complementary information .............................................................................................. 14

5.1 Force sensor types................................................................................................................. 14

5.2 Sensor measuring range........................................................................................................ 14

6. Technical parameters ......................................................................................................... 15

Thank you for selecting our product!

This instruction will help you at correct service and accurate exploitation of described device.

Information included in this instruction were prepared with high attention by our specialists and is description of the

product. Based on the information should not be inferred a certain features or suitability for a particular application. This

information does not release the user from the obligation of own judgment and verification. P.P.H. WObit E.K.J. Ober s.c.

reserves the right to make changes without prior notice.