LUMINOUS™ 570 SERIES LED LIGHT BAR - PAGE 4

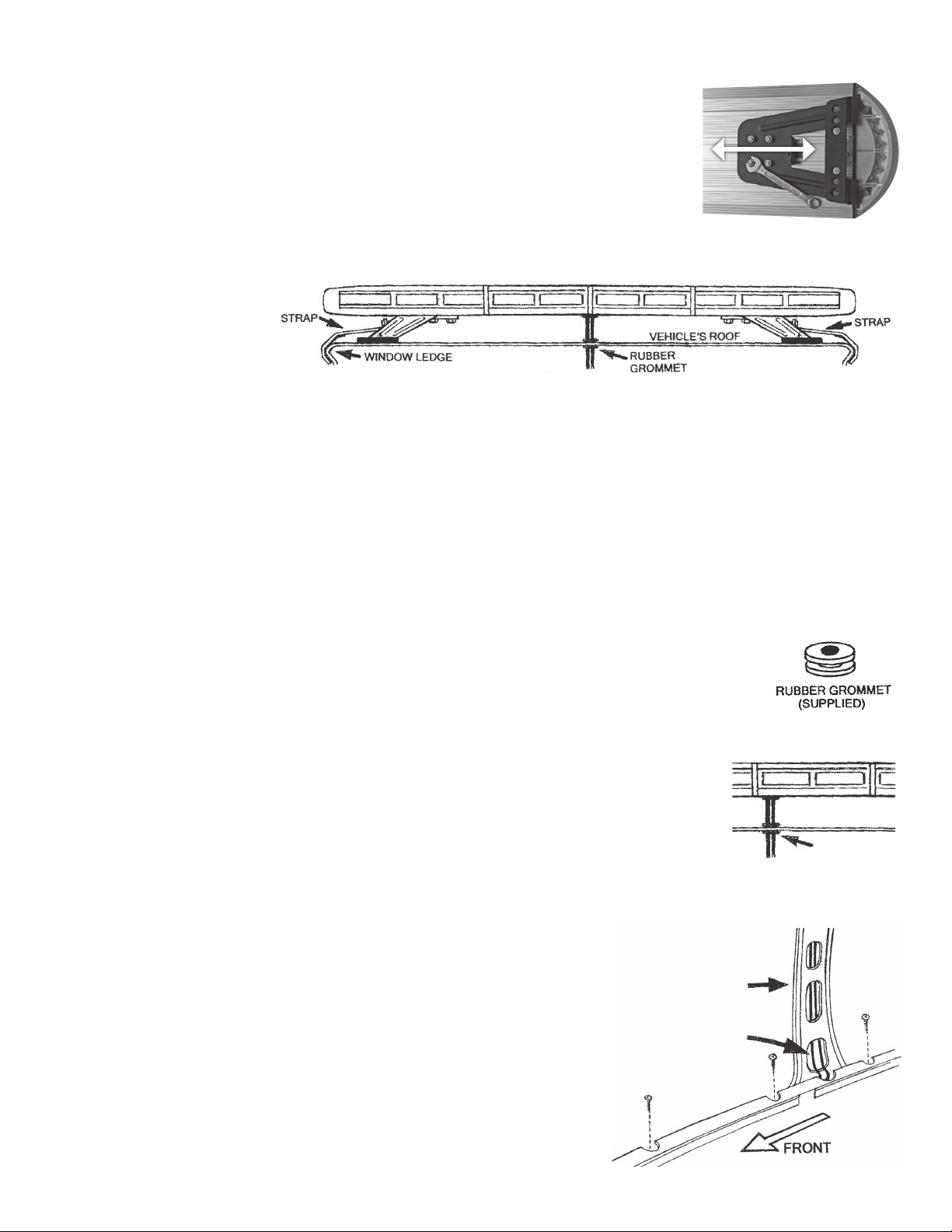

and nuts provided. Insert the tension

adjustment bolt through the strap’s

“L” bracket and thread bolt into the

light bar’s bracket, hand tighten.

IMPORTANT: The “L” bracket can be

repositioned for proper installation by

simply removing the bolt securing it to

the stainless-steel strap. Reposition

and secure the “L” bracket in preferred

location using the bolt, lock washer

and nut. Repeat the procedure for other side of vehicle. WARNING:

The two-(2) stainless-steel straps, included with the light bar are universal

and should always be securely installed to the window’s ledge, using the

hardware provided. Some vehicles may require a custom designed strap to

properly secure the light bar to the vehicle’s window ledge. Always make sure

that both straps have a full hold on the vehicles window ledge. See Fig. 10.

21. Secure the two slide mounting brackets by rmly tighten the four nuts that

were loosened in step 1. See Fig. 5.

22. Tighten the two-(2) tension adjustment bolts evenly. While tightening the

bolts, make sure the light bar remains in the desired mounting position

on the roof. Torque bolts to 10 to 12 ft.- lbs. Failure to properly tighten the

tension adjustment bolts and straps could result in damage to the vehicle

and injury or death to the driver or others. IMPORTANT: Always inspect to make sure that both straps have a full

hold on the vehicles window ledge and the tension bolts are torqued correctly. See Fig. 10.

23. The hooked end of the stainless-steel strap that is engaged to the vehicle’s window ledge has two holes, which

will secure the bracket to the vehicle with the sheet metal screws provided. Use each of the holes in the bracket

as a guide and drill the required holes to size 11/64” into the window ledge. Secure the stainless-steel strap to

the window ledge with the sheet metal screws. IMPORTANT: The installer may have to lower headliner and

inspect the selected location to ensure that there are no components, wires and or any other vehicle part that

could be damaged by drilling. See Fig. 11.

24. Place the weather-stripping back into position on both sides of the vehicle.

MOUNTING & WIRING SWITCH CONTROL PANEL

The light bar’s switch control panel needs to be mounted in a location that can easily be reached. WARNING: If

the vehicle is equipped with air bags, the installer MUST consult the vehicle’s shop or build manual to ensure that

light’s switch controller and wires will not affect deployment of air bags. This switch controller must be installed in

a location recommended by vehicle manufacturer. If necessary, consult manufacturer for their recommendation.

Failure to adhere to this warning could result in damage to the air bag and or reduce the

effectiveness of the air bag, which could result in bodily injury, or death to you or others.

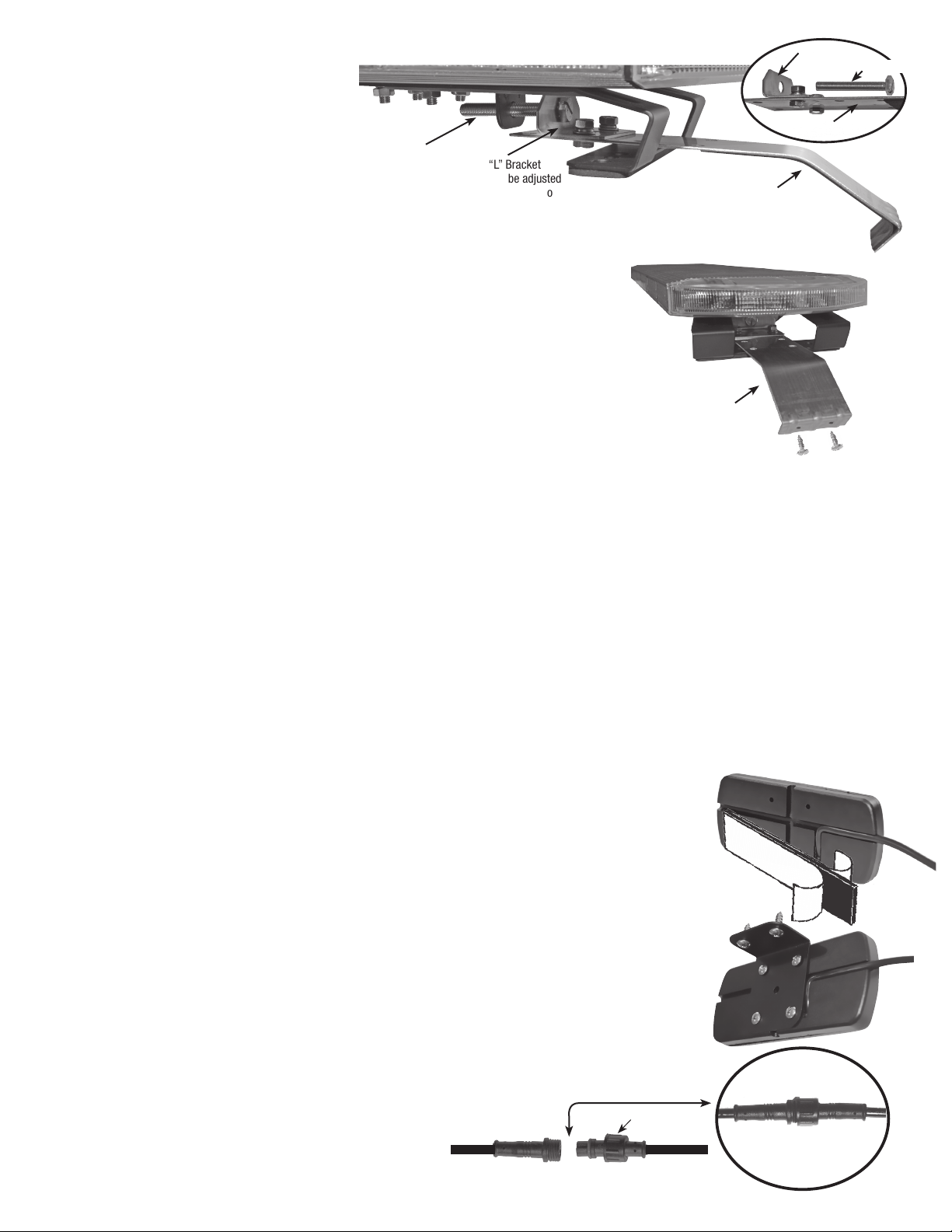

25. NOTE: there are two methods to mount the switch controller, either by using the

double face tape provided or the metal mounting bracket, which is secured to the

mounting surface with screws. IMPORTANT: The installer must inspect the selected

location to ensure that there are no components, wires and or any other vehicle part

that could be damaged by drilling.

26. TAPE METHOD: Position the switch controller’s wire into the slots on the back panel.

Make sure the vehicle’s mounting surface is clean and free of dust, dirt, oil, wax

etc. Using the double face tape provided, secure the control panel to the selected

mounting location. See Fig. 12.

27. SCREW AND BRACKET METHOD: Position the switch controller’s cable into the

slots on the back panel so that the cable is ush with the back panel. Secure the

metal mounting bracket to the back of the switch controller with the four (4) screws

provided. Use the mounting bracket as a template, mark the two screw hole locations

and drill to size 11/16” and secure bracket with two (2) screws provided. See Fig. 13.

28. IMPORTANT: Connect the switch controller’s waterproof plug to the

light bars mating plug which was routed into the vehicle through the

access hole. The plugs can only be connected

in one position. Tighten the shoulder nut fully to

ensure a good waterproof connection. See Fig. 14.

Fig. 12

Fig.

13

Fig. 14

Can only connect in one

position. Match Notch

with Indent

Waterproof

Plug

Fig. 10

“L” Bracket

can be adjusted

to any holes on

Strap as needed

Tension

Adjustment Bolt

Strap

“L” Bracket

Strap

Tension Adjustment Bolt

Drill Hole Size

11/64"

Strap

Fig. 11

Shoulder

Nut