THE HOLLOWING PROCESS

W O O D C U T

-

T O O L S

.

C O M

| #

W O O D C U T T O O L S

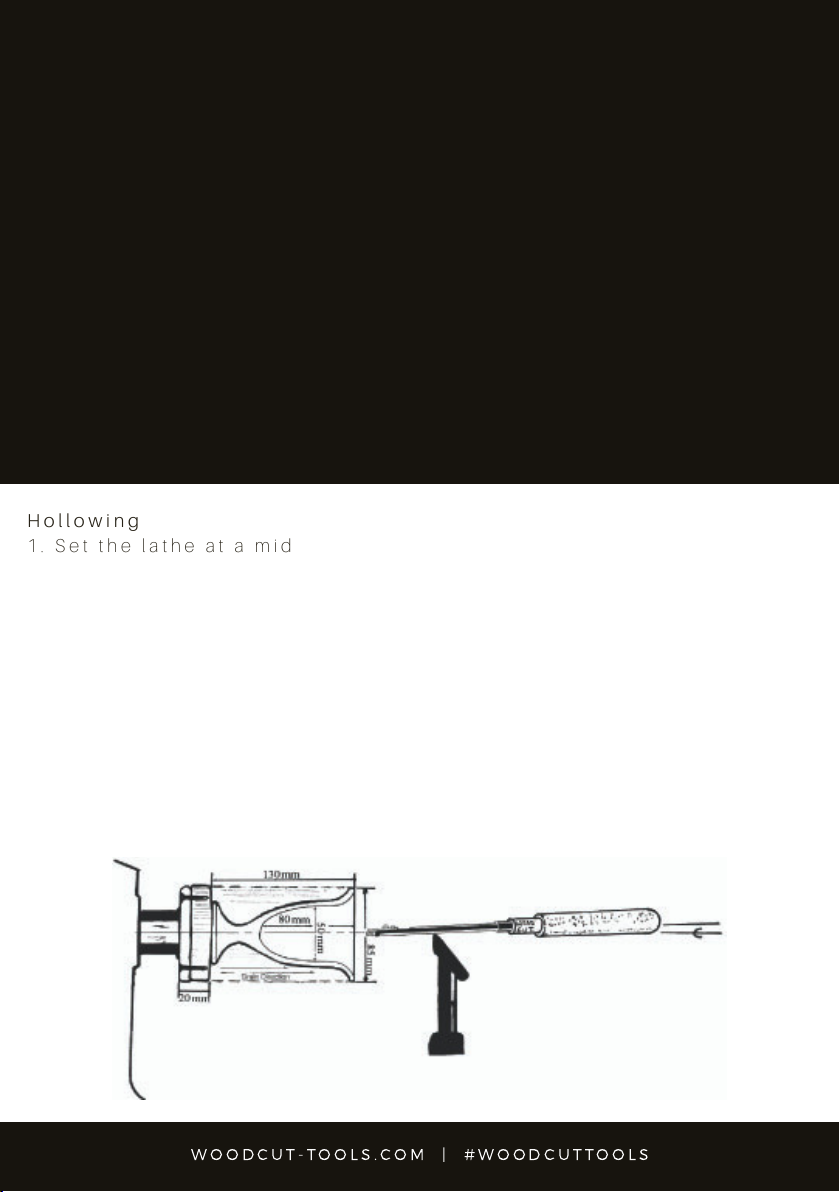

A d j u s t t h e g a u g e t o e n a b l e t h e c o r r e c t a m o u n t o f c u t t e r t o s h o w ,

t h i s w i l l v a r y f r o m a s o f t w o o d t o a h a r d w o o d i . e . s o f t o r g r e e n

w o o d s w i l l h a v e m o r e c u t t e r e x p o s e d ( s a y u p t o a 1 m m o r 3 / 6 4 ” ) a s

o p p o s e d t o h a r d d r y w o o d s ( s a y 0 . 5 m m 1 / 3 2 ” ) . O f c o u r s e w o o d w i l l

v a r y i n s o m a n y w a y s t h a t t h e r e i s n o s u b s t i t u t e f o r e x p e r i e n c e .

T h e s t a i n l e s s s t e e l s e t s c r e w h a s a 7 m m A / F h e a d a n d w i l l a c c e p t a

s o c k e t o r r i n g s p a n n e r o f t h a t s i z e . T o a d j u s t s i m p l y l o o s e n t h e s e t

s c r e w , t h e n h o l d t h e t o o l o v e r a w h i t e p i e c e o f p a p e r , l o o k d o w n

d i r e c t l y f r o m a b o v e a n d m o v e t h e g a u g e b a c k o r f o r w a r d s u n t i l t h e

r e q u i r e d c u t i s a c h i e v e d . T h e n t i g h t e n f i r m l y .

W o o d c u t T o o l s r e c o m m e n d s p r a c t i c e u s i n g g r e e n b r a n c h w o o d .

M a n y f a m o u s w o o d t u r n e r s t u r n a l l t h e i r a w a r d w i n n i n g h o l l o w f o r m s

f r o m g r e e n w o o d , s e a s o n i t c a r e f u l l y a n d t h e n r e t u r n w h e n d r y t o

f i n i s h . P r o v i d i n g i t i s e v e n l y t u r n e d , y o u w i l l b e s u r p r i s e d h o w i t

w i l l d r y c r a c k f r e e , a n d s o m e i n t e r e s t i n g a f f e c t s w i l l o c c u r .

T h e P r o - F o r m e w i l l a l s o h o l l o w f a c e g r a i n t i m b e r . G e n e r a l l y , i f i t s

u n s a f e t o r e a c h w i t h a c o n v e n t i o n a l g o u g e t h e n t h e W o o d c u t

h o l l o w i n g t o o l s w i l l a l m o s t a l w a y s c o m p l e t e t h e f o r m .

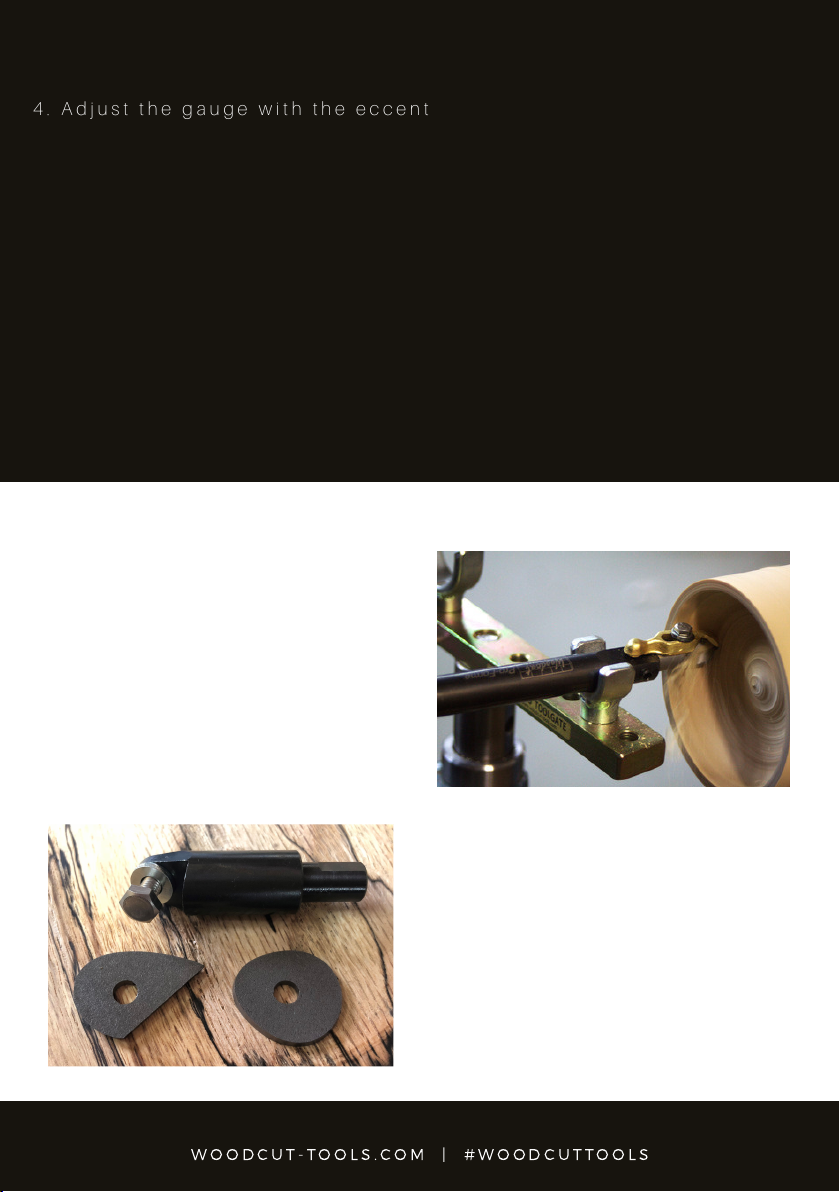

A drilling tool can be produced from a chisel

handle with a long series drill bit in the end where

the tool would be. Simply hold the tool in your

hands level and push into the end grain. Now you

can cut to the centre without experiencing a lump

at the bottom of the hollow form. Roll the tool

anti-clockwise until the gauge is rubbing on the

wood, then with the gauge firmly against the

vessel wall roll the tool back until the required cut

is achieved. You will see the different thickness of

shavings appear as you experiment. Do not use

the tool tentatively. Keep a firm cut at all times.

Wo od cu t To ol s re co mm en ds t ha t yo u st ar t b y h o l l ow in g op en n ec k ve ss el s

un ti l yo u be co me c om fo rt ab le w it h th e fe e l o f t he P ro -F or me t oo l. An o pe n

ve ss el w il l en ab le y ou t o se e wh at t he t o o l i s do in g an d le ar n ho w to h ol d th e

to ol . If y ou a re a tt em pt in g a de ep er v e s s e l , dr il l a 12 mm ( 1/ 2” ) ho le d ow n

th ro ug h th e ce nt re f ir st .