▢

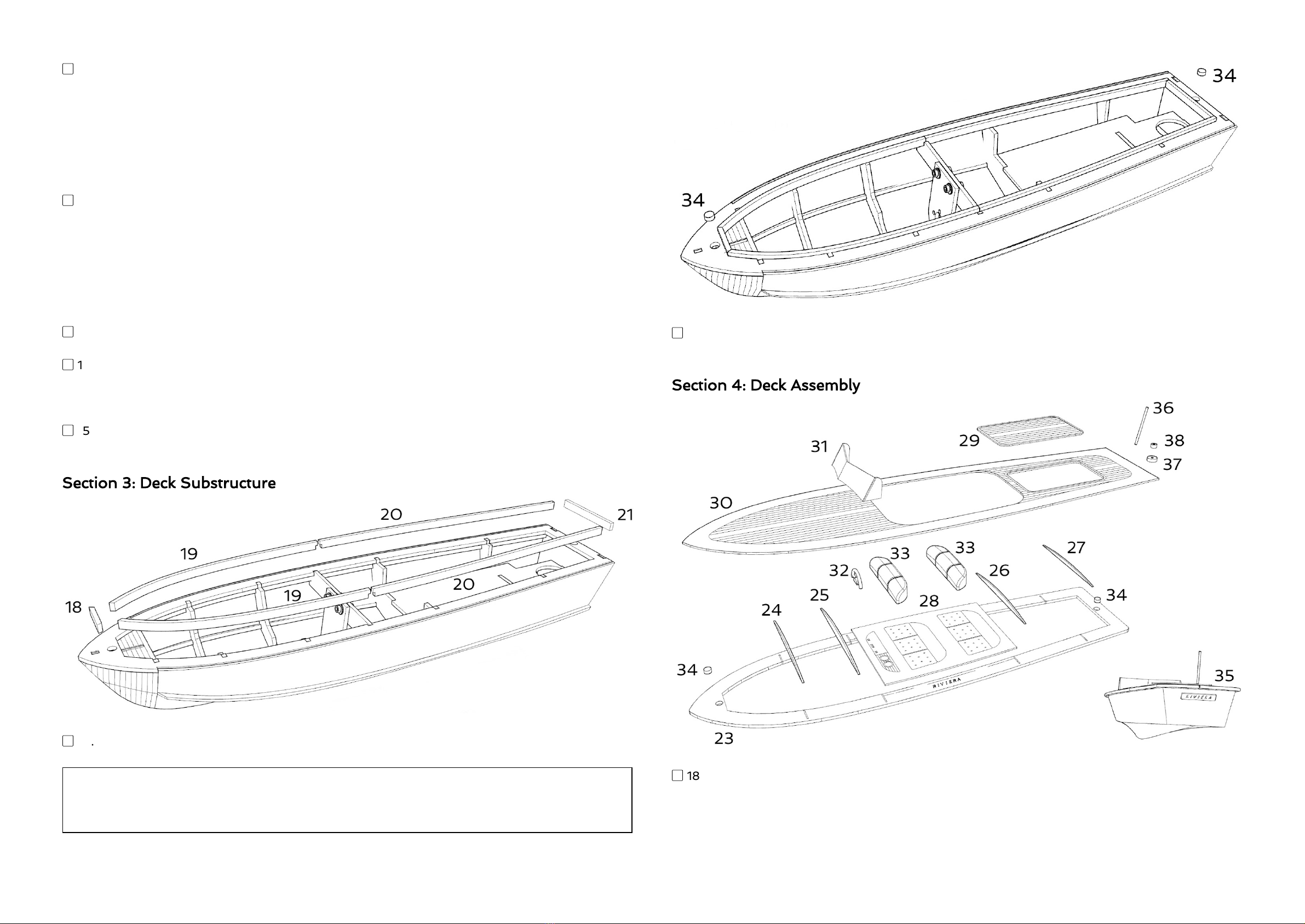

19. Glue the four deck formers (24, 25, 26, 27) and the cockpit floor (28) in position over the

deck frame. Ensure the deck formers remain vertical and are accurately ‘centered’.

▢

20. Locate the printed deck (30) and glue this accurately in position to the deck frame and

formers. If necessary wet the printed side of the wood to assist the bending process. In order for

the deck to clip snuggly onto the hull it’s essential that the deck frame (23) remains absolutely flat

during this process. If necessary use suitably heavy weights to hold the edges of the deck down

while the glue dries.

▢

21. Glue the engine hatch centrally over the hole in the rear deck.

▢

22. Assemble the flag pole and base from parts 36, 37 & 38 and glue to the stern as shown.

Section 5: Finishing

In this section we’ll make the boat waterproof and prepare for final installation of the radio

control and running gear.

▢

23. Unbolt the motor mount bracket (4a) and attach your chosen 280 brushed motor. Refit the

bracket / motor and slide your propeller tube into the hull. Accurately align the tube with the

motor shaft in both the vertical and horizontal planes, then permanently glue the shaft in place

using 15-minute epoxy. TIP! To guarantee alignment use a small piece of tight-fitting neoprene

tube to link the motor and shaft. When the epoxy has set, remove the motor.

▢

24. Trial fit the rudder tube, adjust as required (it should be absolutely vertical), then remove it

for refitting after the hull is painted.

▢

25. Apply two generous coats of Guild Lane sanding sealer to the hull and battery tray (7), leave

to dry between coats and sand after each coat with 800-grit (or similar) paper. If necessary,

repeat until you’re happy that the wood has been suitably sealed. Apply one generous coat of

Guild Lane High Build Primer to the hull, lightly sand with 1200-grit paper and check for

imperfections. Fill as necessary using lightweight filler, sand, re-prime then sand again until the

hull is deemed suitable for the gloss top coats.

▢

26. Add top coats to suit your chosen colour scheme. The prototype uses Guild Lane Gloss

White and Gloss Dark Blue enamel, plus Oratrim Corsair Blue for the trim line (see

Recommended Materials).

▢

27. Stain the deck and nameplate (35) as required (we used Antique Pine woodstain) and seal

with gloss varnish. Again, the prototype uses Guild Lane Gloss Fuel Proofer (see Recommended

Materials).

▢

28. Paint the cockpit floor as desired, along with the steering wheel (32) and seat backs (33),

then glue the steering wheel and seat backs in position.

▢

29. The Perspex windscreen (31) is supplied flat, pre-scored, with a protective film applied. Peel

away the protective film and gently bend the screen along the score lines to form the shape.

CAUTION! Bending the screen in two directions will snap it. The idea is to create a live hinge at

the score lines so that the screen can be formed and glued on in one piece. For this we suggest

Canopy Glue (see Recommended Materials).

▢

30. Locate the remaining deck magnets (34) and glue into the circular pockets in the deck

frame (23) making sure that the correct polarity orientation is observed. Glue the nameplate (35)

in position on the Transom.

Section 6: Motor & Radio Installation

We recommend the Planet TS2+2 two-channel radio system for the Riviera. Designed specifically

for boat and car modellers the stick-style system is supplied with a future-proof 6-channel

receiver and a competitive price tag. Visit jperkins.com for details and pricing and pick one up at

your local model shop.

▢

31. Refit the motor then join the motor shaft and prop shaft using tight-fitting neoprene tube.

NOTE! You may need to shorten the prop shaft by cutting a small length from the non-threaded

end.

▢

32. Fit the propeller and refit the rudder (making sure the O-ring seal is in place between the

rudder tube and hull), then tighten the rudder tube nut and washer against the top of the radio

tray.

▢

33. Attach your servo to the servo and battery tray (7) using double-sided servo tape and use a

piano wire pushrod to link it to the tiller arm.

▢

34. Use padded double-sided tape to attach your receiver (forward of the rudder servo), then

test the model for balance, in water. Establish the ideal location for your chosen 2S LiPo battery

then attach it using hook and loop tape. Check for leaks and rectify.

HAPPY CRUISING

The Riviera drives well in most conditions but, like all small model boats, excels in calmer water

and looks very much the part, displacing a satisfying bow wave and leaving a tidy wake. Steering

is positive and with the 280 motor / 2S LiPo combination the speed is beautifully matched to the

type. Don’t be tempted to over-power it. The Riviera has a semi-displacement (rather than a

planing) hull and is not designed for out-and-out speed. Like the full-size motor boat it

resembles, this is a gentleman’s Sunday cruiser and is best driven accordingly.

We hope you’ve enjoyed building this model and are suitably enthused to try other boats in

the Wooden Model Boat Company range.