SM3120-14F Page 7 of 7 © Woodhead Feb-08

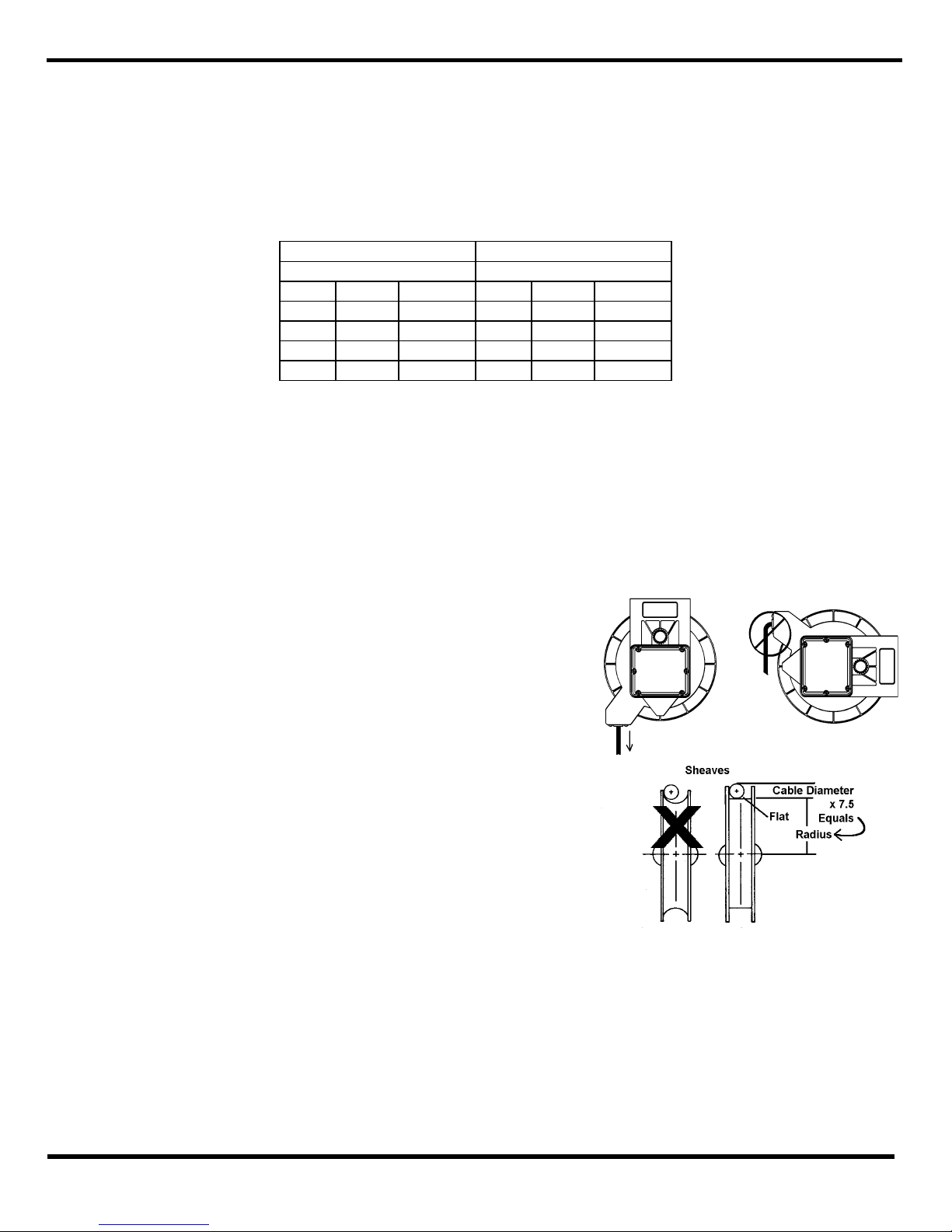

POW-R-MITE REEL REFERENCE CHART FOR REELS WITH CABLE INCLUDED.

Reel Includes Cable:

Model Cable

Number Length

(ft) Size OD” Reel w/o

Cable #

9224 85-1630 31 16-3 .430 095105203

9228 85-1630 51 16-3 .430 095105203

9234 85-1640 31 16-4 .485 095105204

9238 85-1640 51 16-4 .485 095105204

9253 85-1430 26 14-3 .560 095105203

9358 85-1430 51 14-3 .560 095104203

9363 85-1440 26 14-4 .605 095104204

9367 85-1440 46 14-4 .605 095104204

9383 85-1230 26 12-3 .640 095104203

9385 85-1230 36 12-3 .640 095104203

9394 85-1240 31 12-4 .670 095104204

9242 85-1030 21 10-3 .695 095105203

9206 86-1660 46 16-6 .565 095105206

9208 86-0202 39 16-8 .645 095105208

9306 85-0506 36 14-6 .740 095104206

9308 86-0203 21 14-8 .795 095104208

92481 86-0202 51 16-8 .645 095106208

92401 AMR62120150 31 16-10 .720 095106210

92411 87-0108 31 16-12 .740 095106212

92482 86-0203 31 14-8 .845 095106208

92402 86-0803 21 14-10 .905 095106210

92433 85-1230 51 12-3 .640 095106203

92443 85-1240 41 12-4 .670 095106204

92463 85-0508 31 12-6 .800 095106206

92483 86-0204 21 12-8 .915 095106208

92434 85-1030 41 10-3 .695 095106203

92444 85-1040 31 10-4 .750 095106204

92464 85-0510 21 10-6 .880 095106206

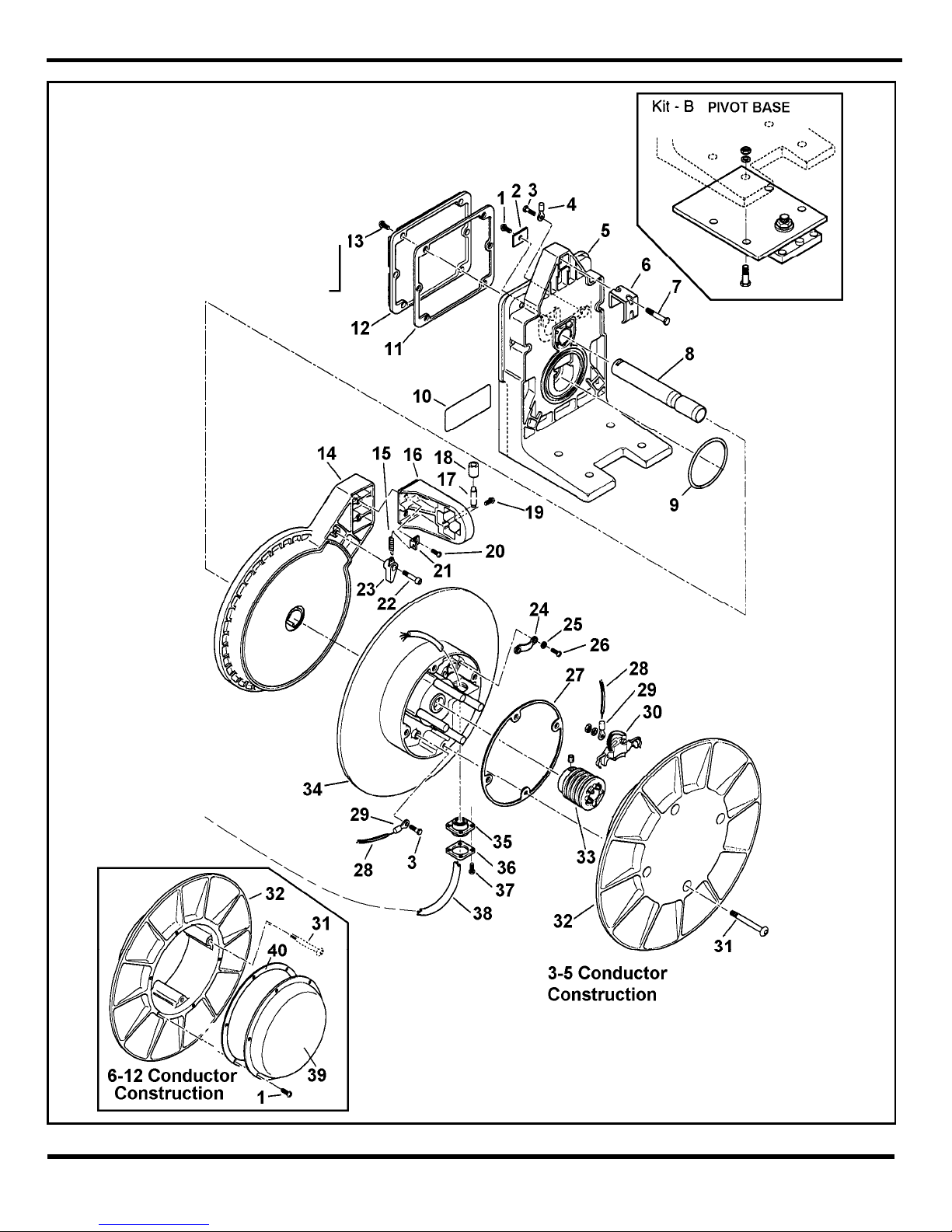

Reference

Number

Part Number

Qty.

Description

AMC03500231 1 Screw pan head M5x12mm

1 AMC03500231 7 Screw pan head m5x12mm 6-12 conductors

2 AMM41100003 1 Shaft retainer

3 AMC03510130 2 Bolt hex head M5x10mm

AM00041P0127 1 Terminal - for #10-#12 AWG wire

4 AM00041P0126 1 Terminal - for #16-#14 AWG wire

5 AMM04160004 1 Base

6 3 Clamp-Included in Clamp Kit “D” below.

7 3 Bolt hex head M6-Included in Clamp Kit “D” below.

AMM34370002 1 Main shaft – 3 to 5 conductors

AMM34370003 1 Main shaft – 6 to 8 conductors

8 AMM34370004 1 Main shaft – 10 to 12 condcutors

9 AMC47040141 1 O-ring

10 1 Name plate

11 AMM14240007 1 Junction box gasket

12 AMM04540004 1 Junction box cover

13 AMC03500253 6 Screw pan head M6x16mm

AMH41220074 1 Spring pocket assembly -- 0951-04-xxx

AMH41220075 1 Spring pocket assembly -- 0951-05-xxx

AMH41220076 1 Spring pocket assembly -- 0951-06-xxx

AMH41220078 1 Spring pocket assembly -- 0951-08-xxx

14

AMH41220079 1 Spring pocket assembly -- 0951-09-xxx

15 AMC60610121 1 Extension spring

16 AMM04730007 1 Cable guide frame See Kit “E”

17 AMM24060125 4 Roller shaft See Kit “E”

18 AMM86700006 4 Roller See Kit “E”

19 AMC03500253 4 Screw pan head M6x16mm See Kit “E”

20 AMC03500255 2 Screw pan head M6x20mm See Kit “E”

21 AMM53350002 1 Spring clip

22 AMC15070225 1 Screw shoulder M8x10x16

23 AMM86750002 1 Ratchet pawl

24 AMM70780007 1 Cable clamp

25 AMC01070517 2 Flat washer M5

26 AMC03500233 2 Screw pan head M5x16 OD .380-.539