TABLE OF CONTENTS 1____________________________________________

INTRODUCTION 2__________________________________________________

INTENDED USE 3__________________________________________________

TECHNICAL SPECIFICATIONS 3______________________________________

TOOLS REQUIRED 3_____________________________________________

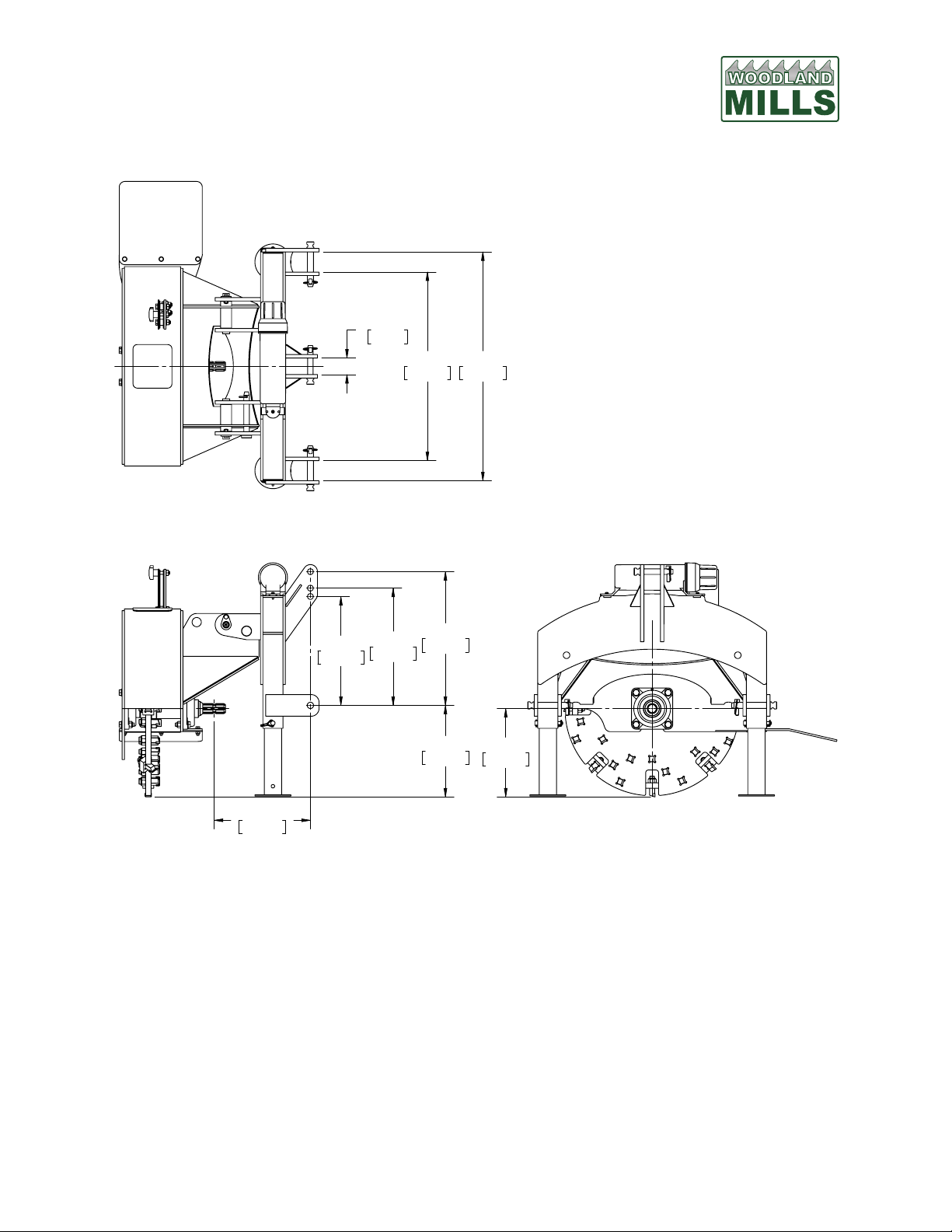

OVERALL DIMENSIONS 4_________________________________________

3-POINT HITCH DIMENSIONS 5____________________________________

GENERAL SAFETY RULES 6_________________________________________

PERSONAL SAFETY 7______________________________________________

MACHINE USE AND CARE 8_________________________________________

ASSEMBLY 9______________________________________________________

1. DEFLECTOR 9_______________________________________________

2. MANUAL TUBE 10_____________________________________________

SET-UP PROCEDURES 11___________________________________________

TRIMMING THE PTO SHAFT 11_____________________________________

PTO SHAFT CLUTCH RUN-IN 13____________________________________

FLYWHEEL TOOTH TORQUING 15__________________________________

EQUIPMENT OPERATION 16_________________________________________

STUMP GRINDING PROCEDURE 19________________________________

INCORRECT GRINDING PROCEDURES 20___________________________

PULLING THROUGH THE CENTRE 20_____________________________________

GRINDING LEFT-TO-RIGHT 20___________________________________________

CHAINSAW HOLDER 21___________________________________________

STORAGE 21___________________________________________________

MAINTENANCE 22_________________________________________________

REPLACING TEETH 22___________________________________________

PARTS LIST 23____________________________________________________

EXPLODED ASSEMBLY 24__________________________________________

NOTES 25________________________________________________________