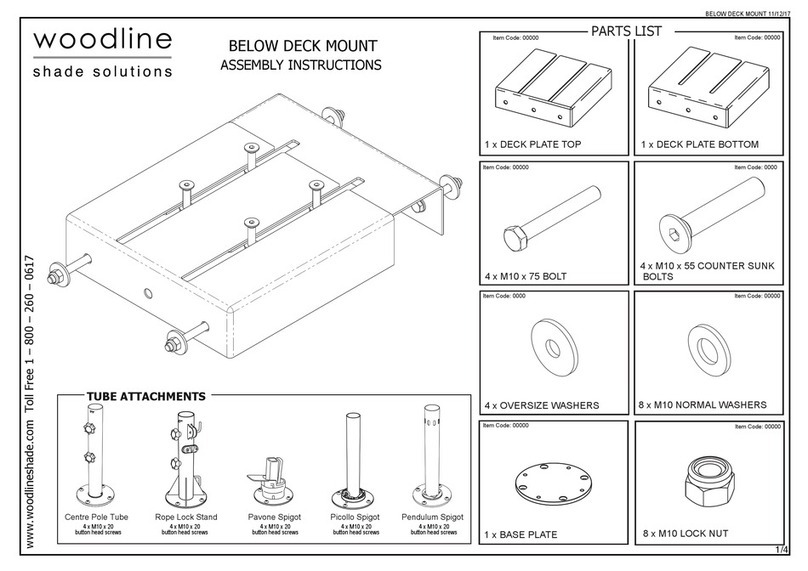

Every Woodline shade solution is meticulously engineered to maximize not just their form and functions, but also to make sure that they

outlast even the harshest conditions. Each item is crafted from the finest marine grade weather-resistant materials, specifically selected

for their ability to endure. Though our shade solutions are built to last, the relentless and extreme nature of the outdoors dictates that

proper care and maintenance will always extend the lifespan of any item.

FRAMES

FITTINGS

WOODEN COMPONENTS

BASES

FABRICS

Constructed from the finest quality aluminum, high grade stainless steel and

durable and sustainable eucalyptus timber. Our frames have been tested in

some of the world’s most inhospitable environments and have only ever bene-

fited from the appropriate application of caution and common sense in exces-

sive wind conditions.

We advocate the use of our cover bags to prolong the life of the canopy

frames and their covering fabrics. We recommend the closure and safe

storage of any collapsible and removable components when the parasol is not

in use or when winds are expected to exceed 24.8 mph (40 km/h).

All fittings, nuts, bolts, pulleys and cleat components are made with high

grade stainless steel and weatherproof nylon. Maintaining these fittings and

components is imperative to the longevity and the proper operation of the

shade system. A simple occasional fresh water rinsing will help keep them

working well and looking good.

It is essential to pick the right base for your parasol, talk to our sales team to

ensure that the parasol you choose has the appropriate base to keep it

anchored properly.

Our canopies and fabric covers are made from the most durable, colorfast,

and dirt-repellent fabrics in the world. That said, proper care such as storage

when not in use and cleaning from time to time will undoubtedly extend

their lifespan.

WIND GUIDELINES

*The umbrella should always be closed during very windy conditions. As with

all umbrellas, common sense wind guidelines prevail: if it is too windy to enjoy

sitting outside under the umbrella, the umbrella structure should be lowered,

folded and secured with the strap.

*When unattended, the umbrella structure should always be left in the closed

position with the canopy folded properly, securely strapped with the cover bag

placed over the umbrella.

*The umbrella structure must always be lowered, properly folded and strapped

during heavy rains, thunderstorms, hail or any other severe weather condi-

tions. Always anticipate to give time to properly fold the canopy, as during

severe conditions if not folded properly, the fabric may become damaged.

*If very extreme weather conditions are anticipated, the umbrella structure

should first be lowered, folded properly, strapped and placed in the cover

bag. Then the entire umbrella structure should be removed from the base and

stored in a clean, dry location.

8/8

CARE AND MAINTENANCE

UV RESISTANT WATER/STAIN RESISTANT BREATHABLE MOLD RESISTANT EASY CARE PROTECTS FROM UV

We only use sustainable eucalyptus timber hand-picked for its strength, weath-

er-resistance, and replenishment efficiency from the world’s finest FSC-ac-

credited plantations and timber mills. Our wooden components are treated

with marine yacht varnish to fortify them for outdoor living.

We recommend the periodic care of wooden components

with a light sanding and reapplication of the varnish coating

once a year to maintain the natural beauty of the wood.

www.woodlineshade.com Toll Free 1 – 800 – 260 – 0617

06 July 2021