6 Safety MAN1354

(01/24/2024)

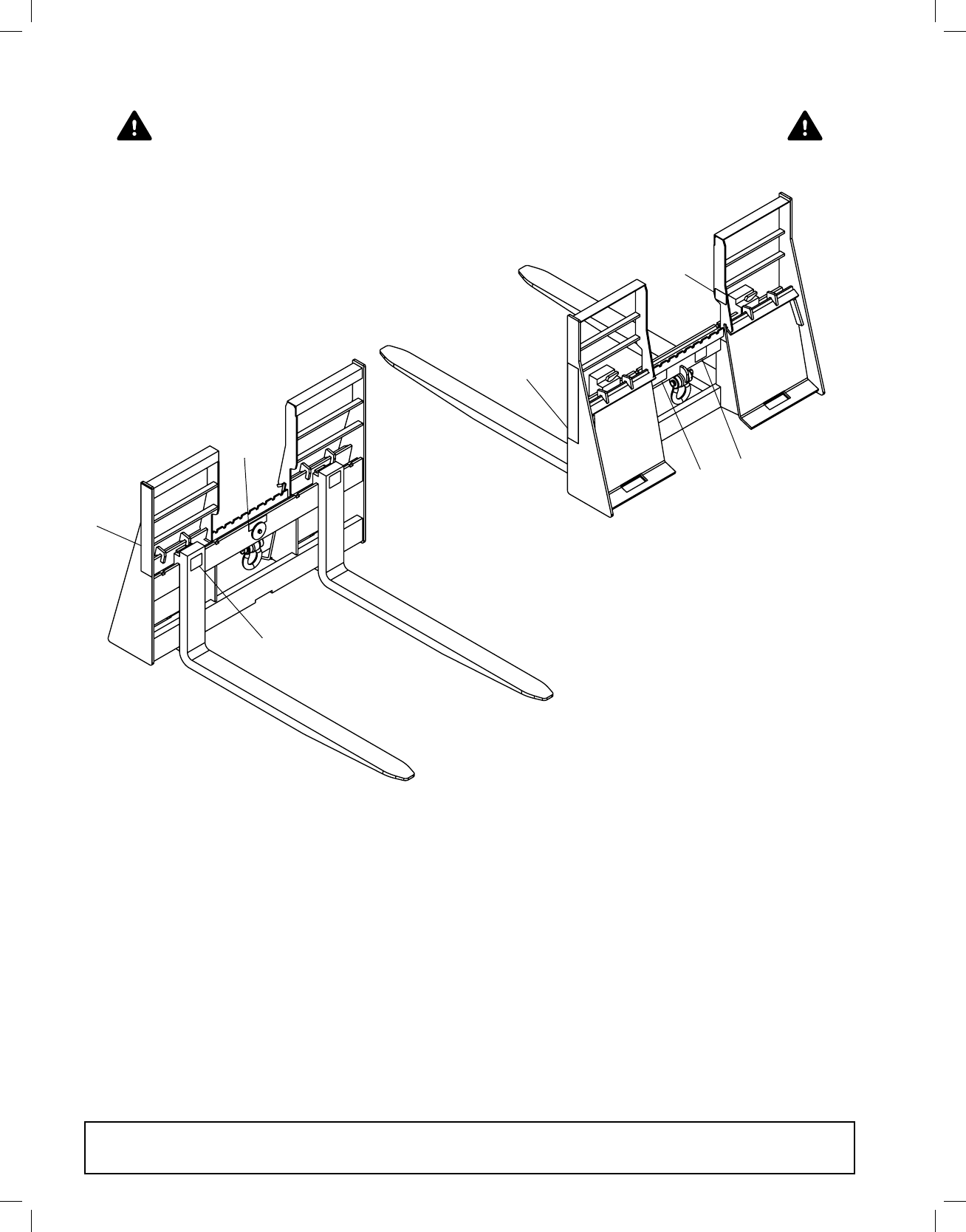

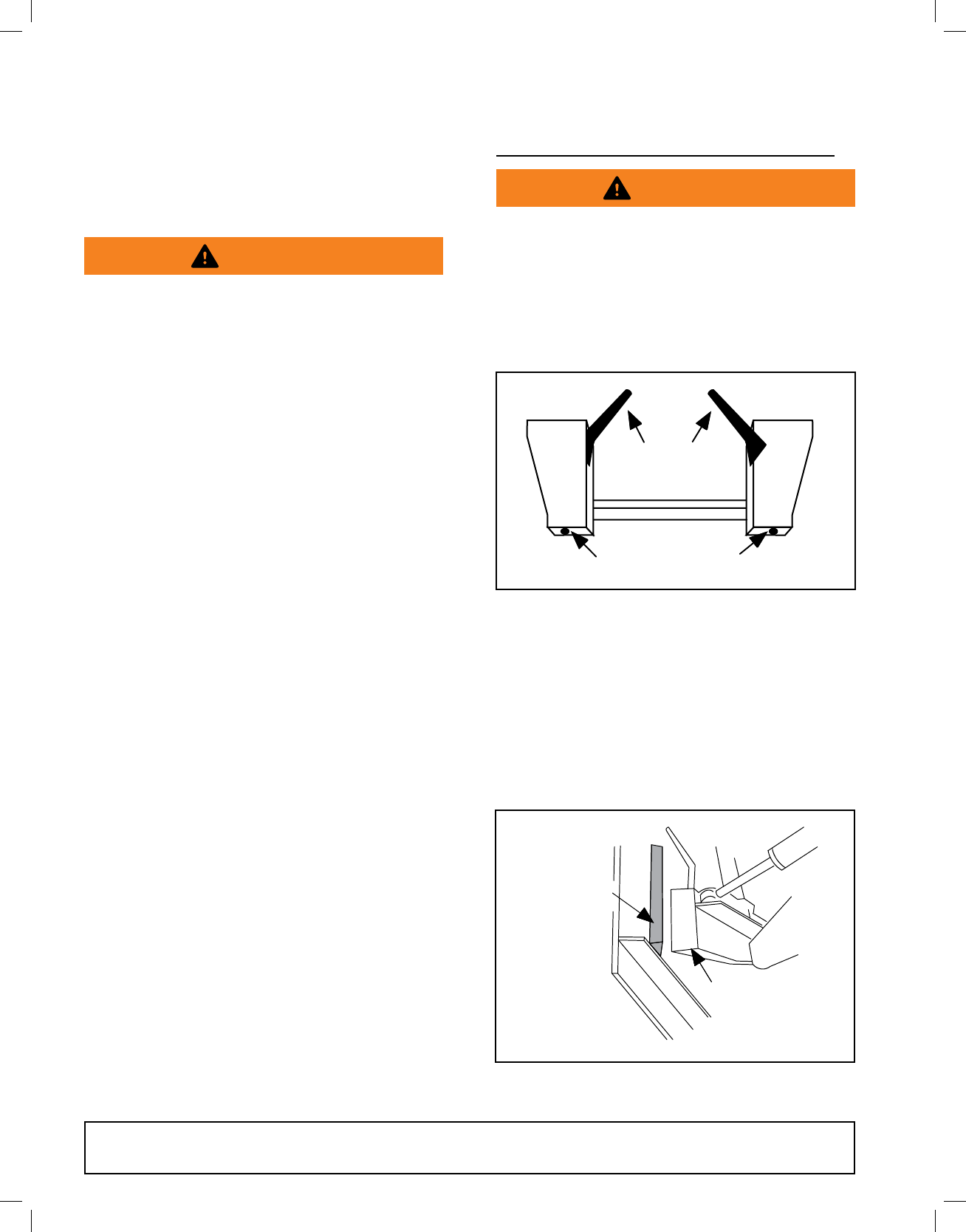

■Do not put Pallet Fork into service without

forks properly engaged on frame rails and fork

lockplate secured in place. Fork locks must

be engaged into fork lock notches. Replace if

damaged.

■Consult local utilities before digging. Know lo-

cation and depth of all underground cables,

pipelines, and other hazards in working area

and avoid contact.

■Contact with high voltage, overhead power

lines, underground cables, gas lines, and other

hazards can cause serious injury or death from

electrocution, explosion, or re.

■Keep bystanders away from equipment.

■Do not operate or transport equipment while

under the inuence of alcohol or drugs.

■ Operate only in daylight or good articial light.

■Keep hands, feet, hair, and clothing away from

equipment while engine is running. Stay clear of

all moving parts.

■Always comply with all state and local lighting

and marking requirements.

■Do not allow riders. Do not lift or carry anybody

on the power unit or attachments.

■Always sit in power unit seat when operating

controls or starting engine. Securely fasten

seat belt/operator restraint, place transmission

in park or neutral, engage brake and ensure all

other controls are disengaged before starting

power unit engine.

■Look down and to the rear and make sure area is

clear before operating in reverse.

■Use extreme care when working close to fences,

ditches, other obstructions, or on hillsides.

■Use caution when handling loose or shiftable

loads.

■Do not operate or transport on steep slopes.

■Allow for forklift length when making turns.

■Stop the forks gradually when lowering or lifting.

■Do not stop, start, or change directions sudden-

ly on slopes.

■Use extreme care and reduce ground speed on

slopes and rough terrain.

■Watch for hidden hazards on the terrain during

operation.

■Stop power unit and implement immediately

upon striking an obstruction. Dismount power

unit, using proper procedure. Inspect and repair

any damage before resuming operation.

■Leak down or failure of mechanical or hydraulic

system can cause equipment to drop.

■AVOID INJURY OR DEATH FROM FALLING

OBJECTS:

• Do not carry shiftable items. Hay bales, logs,

fence posts, stones, and other objects can

roll or fall from a raised attachment and

crush operator or children, bystanders or

animals.

• This unit is not equipped with any method to

prevent objects such as round bales, posts,

or logs from rolling back onto operator.

• Do not handle round hay bales.

• Carry loads low and drive slowly.

• Do not carry large objects that can fall out of

attachment into operator zone.

• Never lift load higher than necessary to clear

the ground when moving.

■Before leaving operator’s seat, lower lift arms

and put attachment on the ground. Engage

brake, stop engine, remove key, and remove

seat belt.

MAINTENANCE

■NEVER GO UNDERNEATH EQUIPMENT. Never

place any part of the body underneath equip-

ment or between moveable parts even when the

engine has been turned off. Hydraulic system

leak-down, hydraulic system failures, mechan-

ical failures, or movement of control levers can

cause equipment to drop or rotate unexpectedly

and cause severe injury or death.

• Service work does not require going

underneath.

• Read Operator’s Manual for service in-

structions or have service performed by a

qualied dealer.

■Before performing service work that requires re-

pair or replacement of parts, remove attachment

from power unit. Hydraulic system failures, me-

chanical failures, or movement of control levers

can cause equipment to drop or rotate unex-

pectedly and cause severe injury or death.

■Do not modify or alter or permit anyone else to

modify or alter the equipment or any of its com-

ponents in any way.

SAFETY RULES

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

MAN1354_2024-01.indd 6MAN1354_2024-01.indd 6 1/24/24 12:37 PM1/24/24 12:37 PM