43730 E. SOUTHERN AVE., PHOENIX, AZ 85040 | USA

SAFETY INFORMATION

WARNING!

RISK OF ELECTRICAL SHOCK! Turn ALL power to the unit OFF before service.

All service should be done by or under the supervision of a trained technician.

THIS ELECTRIC FLASH CURE UNIT IS INTENDED SOLELY FOR THE PURPOSE OF CURING

INK ONTO FINISHED TEXTILES AND CUT GOODS. THIS FLASH IS NOT INTENDED FOR

USE IN HEATING, CURING OR BAKING OF ANY OTHER MATERIALS WHATSOEVER. THIS

FLASH IS INTENDED FOR IN-DOOR USE ONLY.

THE EXCLAMATION WITHIN AN EQUILATERAL TRIANGLE IS INTENDED TO ALERT THE

USER OF IMPORTANT SAFETY PRECAUTIONS SHOP PERSONNEL SHOULD BE AWARE

OF DURING OPERATION.

For your safety, do not store or use gasoline or other flammable vapors and liquids in the vicinity

(at least three feet) of this or any other appliance.

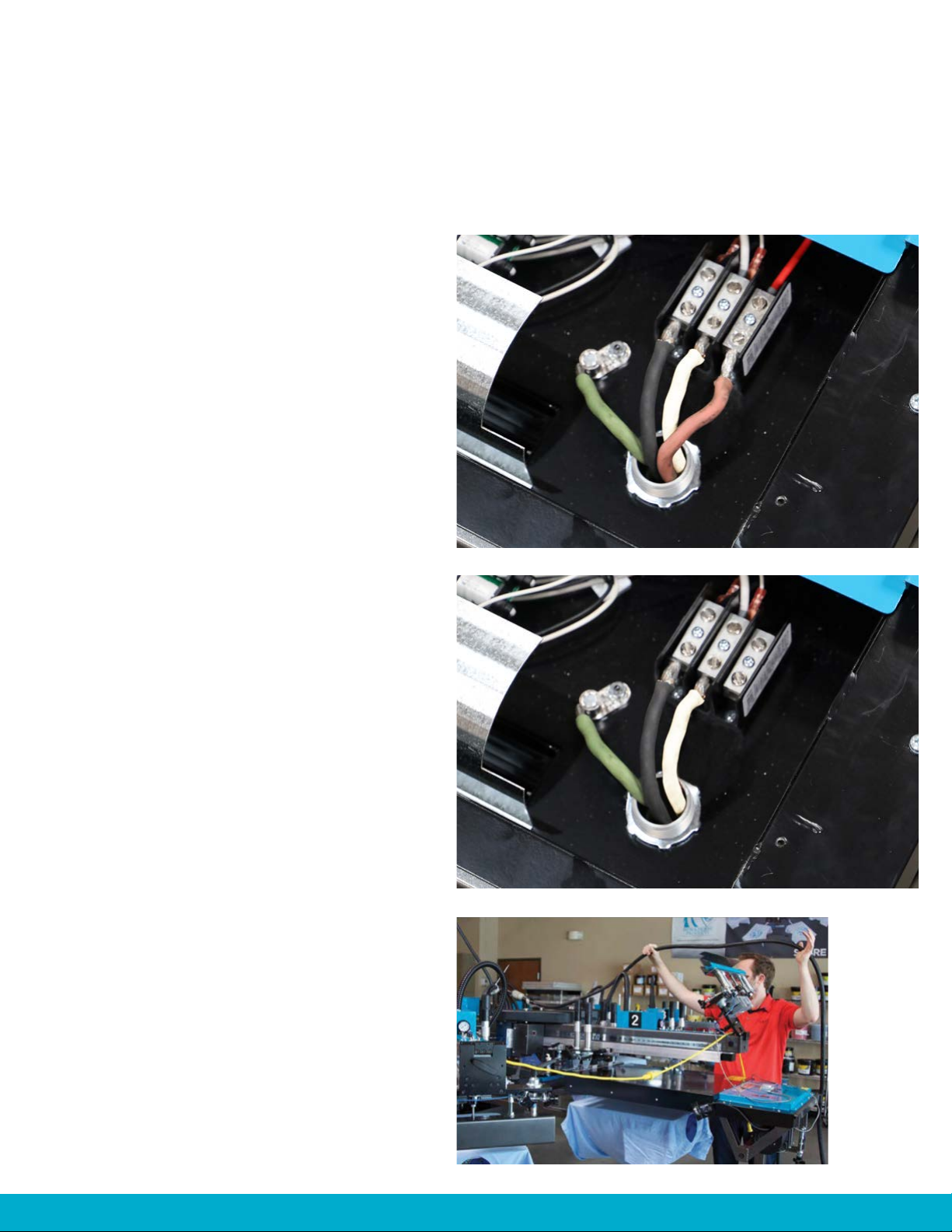

Proper grounding (a ground rod at the equipment footing), according to NEC requirements, must

be provided during electrical connection by a QUALIFIED ELECTRICIAN.

Never alter the internal wiring of this machine.

Never place any item other than the stock to be cured under the flash heaters.

Once in position lock wheels before using the flash unit.

Keep all loose articles (including clothing, hair, jewelry, etc.) away from the hot elements.

Never leave the machine unattended when it is operating.

Do not perform maintenance on this machine until all power has been shut off at the flash AND at

the incoming power circuit breaker. Also, disconnect the control cable leading to the machine.