Customer record:

Please note the product model, serialnumber on the nameplate of the productandcomplete the following line.

Whenyou contact the distributoror supplierforafterservice, please use theserial number.

Model: Serialnumber:

Cautions:

Please read all the safety and operation procedures in the instruction manual before you use this product.

Following the instructions will help you operate this device safely and easily.Please always operate the device in strict

accordance with the instructions provided.

Please retain the instructions and customer record in safe place.

If you encounter difficulties, or have any questions regarding the use, or safe operation of the device, please contact

yourlocal distributor immediately. Your safety and satisfaction is our primary mission.

1. Introduction

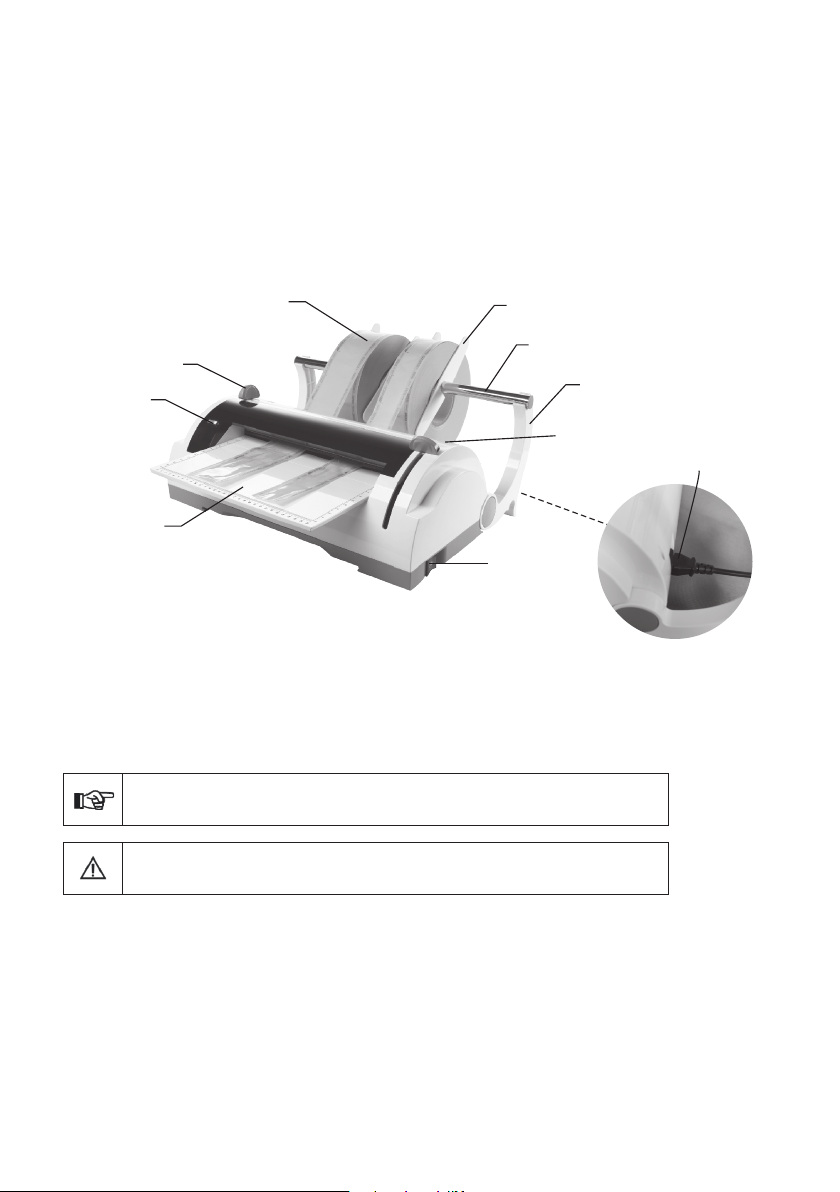

SELINA is the Thermo-sealing machine which fits as a natural complement to the range of steam sterilizer.

It is an elegantly, space-saving designed piece of equipment that is both user-friendly and reliability, even with heavy

use.

SELINA is therefore a useful option for all those users who require professional equipment with an excellent ratio of quality to

price and performance.

SELINA is an electronically controlled thermo-sealer with a sealing band of 12 mm fit to resist the sterilization processes of the

modern sterilizers featuring fractioned pre-vacuum, and to assure in time the sterility of the packages.

Efficient heat control in the sealing area is achieved thanks to the automatic temperature adjustment, ensuring high

and constant performance.

The solid structure in plastic and aluminum and the ergonomic and minimalist shape help to maintain a high level of

hygiene, weight and overall size and excellent stability during use.

All this with the objective of offering a product suited to the daily needs in the medical/dental area.

For a good operation of the thermo-sealer the first and essential task is its correct installation; in this way possible

malfunctions or damages to the unit will be avoided.

2